Amphiphilic peptide matrices for treatment of osteoporosis

a technology of amphiphilic peptides and matrices, applied in the field of therapeutic methods, can solve the problems of increased fracture risk, increased fracture risk, and increased morbidity and mortality of osteoporotic vertebral fractures, and achieves the effects of high fracture risk, improved treatment effect, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

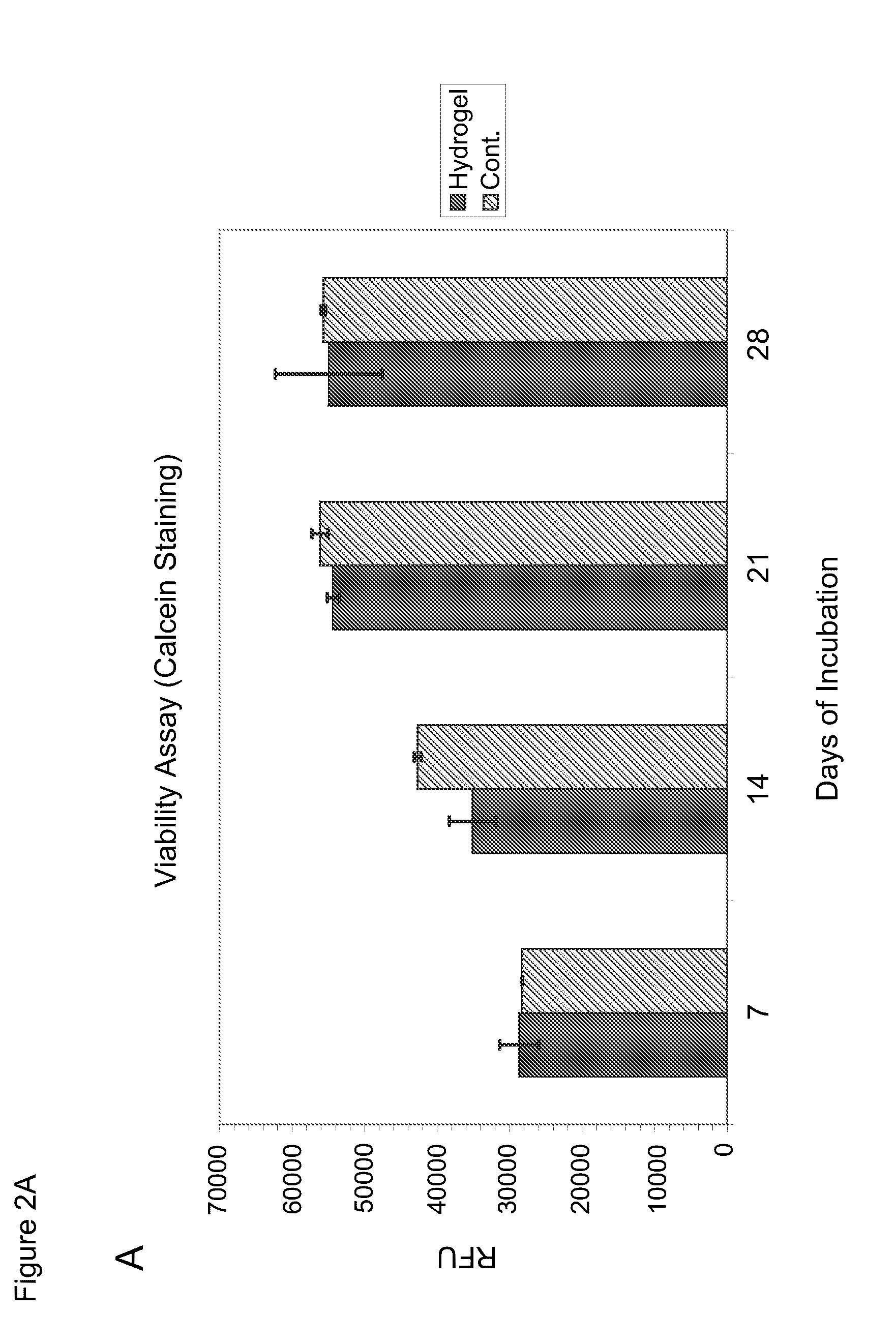

Image

Examples

example 1

Peptide Synthesis

[0184]The peptides were synthesized by conventional solid phase synthesis methods, using either tBOC or FMOC chemistry. The peptides of the invention may further be prepared using recombinant DNA techniques known in the art.

example 2

Preparation of Peptide Hydrogel

[0185]According to a specific example the matrix is formed in the following way: dissolving the peptides at high pH (above about pH 8) using either buffer (Tris) or NaOH. With the addition of the peptide the pH of the mixture drops and hydrogel is formed. The peptide that is dissolved in alkaline solution may also be titrated with HCl to a pH ˜7 to form a gel. The same can be done with HA or other mineral particles incorporated in the first step (low pH). Upon gelation the particles get trapped in the gel.

example 3

[0186]In vitro biomineralization was performed with monolayer peptide films deposited on SBF1.5 solution (×1.5 ionic profile of blood serum Tris buffered to pH 7.35; Na+ 213.0, K+ 7.5, Ca+2 3.8, Mg+2 2.3, HCO3− 6.3, Cl− 223.0, HPO4− 1.5, SO4− 2 0.75 mM). Mineralization was also obtained on hydrogels that were in contact with SBF1.5 solution.

[0187]A considerable amount of work has been done in-vitro in order to decide whether acidic amino acids are indeed effective in HA formation. Usually these studies are done by exposure of surface active material to ionic solution followed by evaluation of HA nucleation degree on this surface. Ionic solutions, in which nucleation occurs, have a few variables such as, minerals components and their concentrations, buffer capacities, pH, temperature and preparation procedures. The two essential components of SBF1.5 are calcium and phosphate. The solution was prepared according to the prototype-SBF procedure developed by Kok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com