Multi-layered carbon substrate for gas diffusion layer

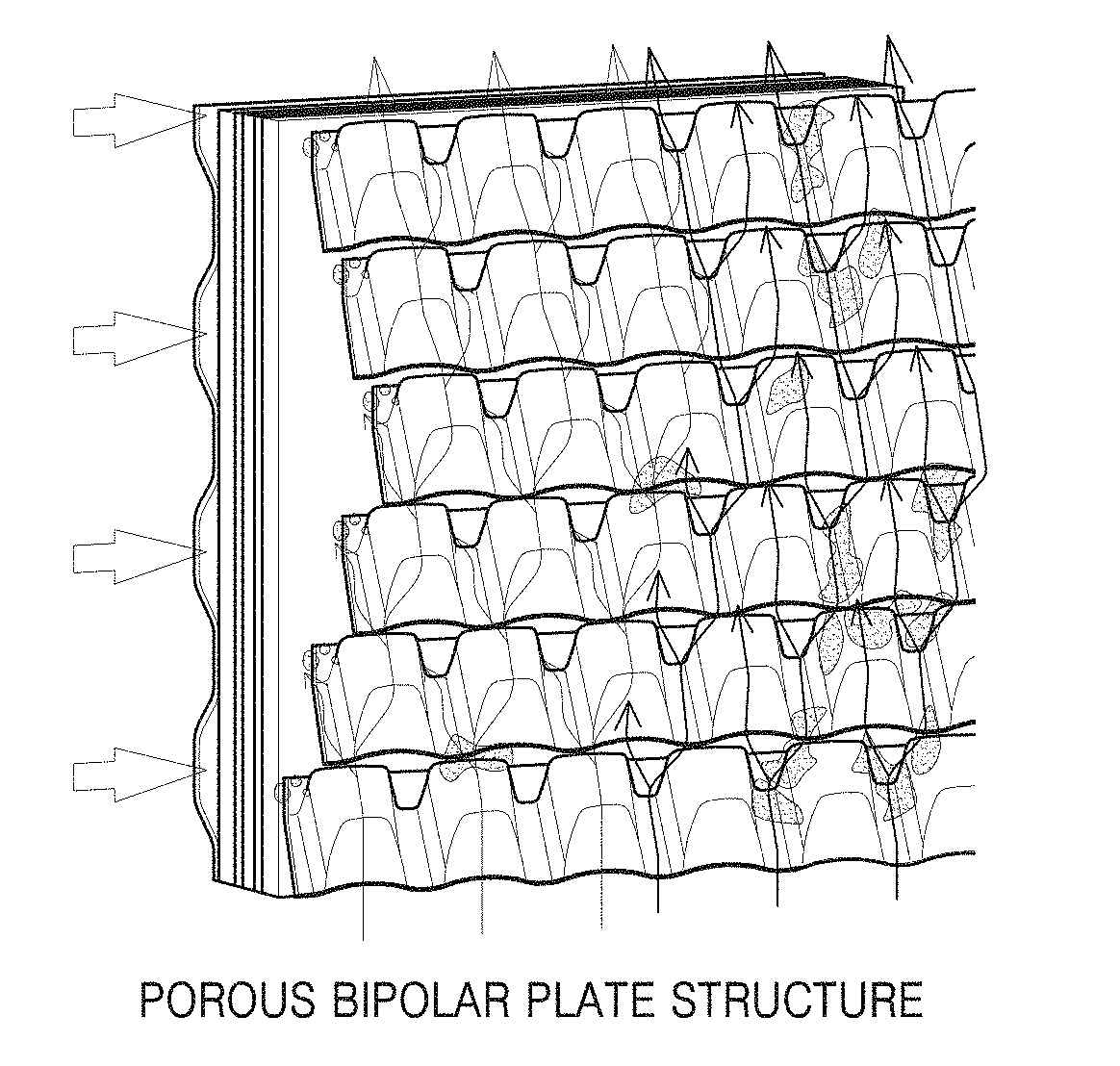

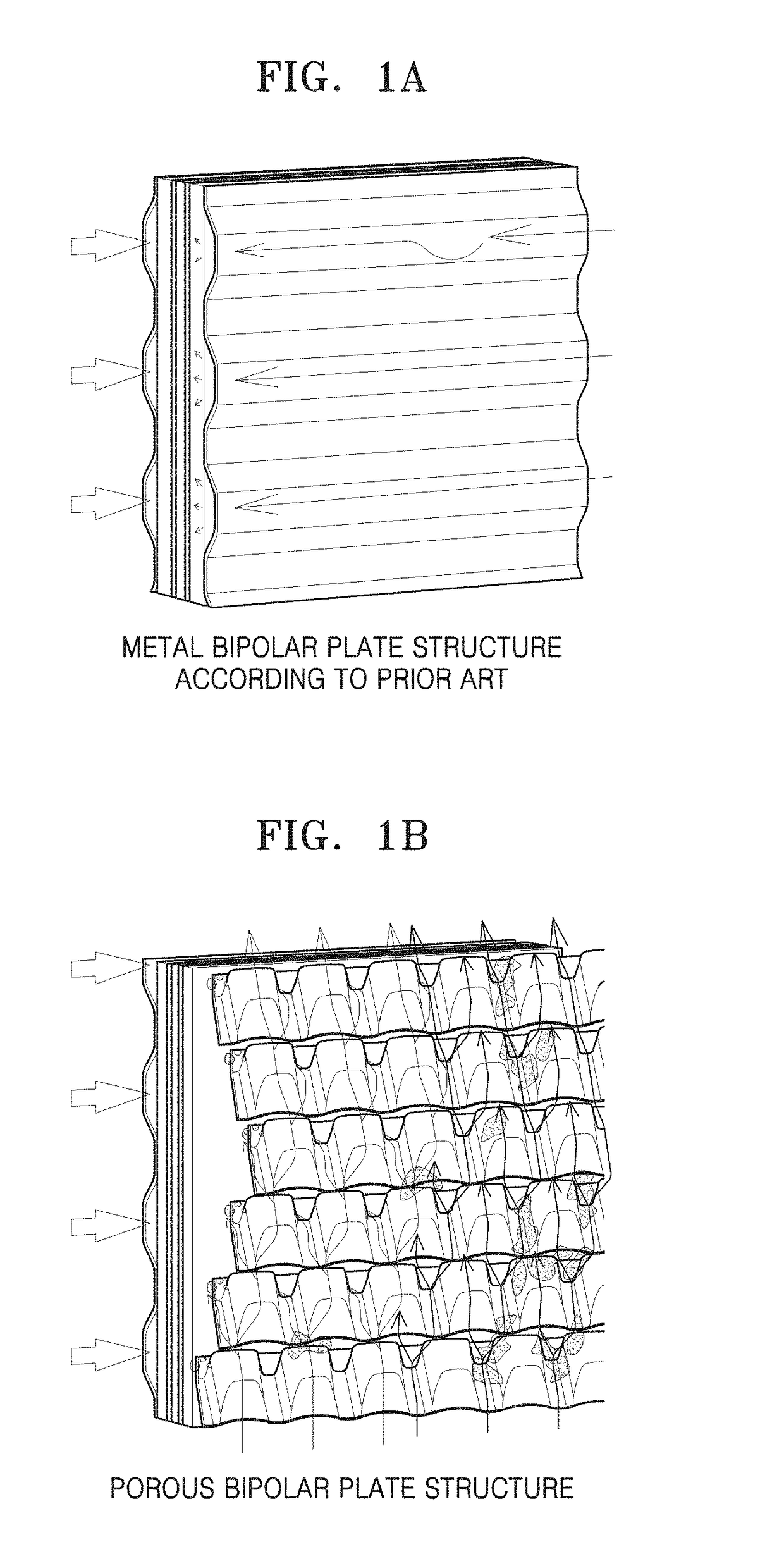

a carbon substrate and gas diffusion technology, applied in cell components, electrochemical generators, batteries, etc., can solve the problems of increasing the power consumption of pumps, shrinking or expanding stacks of pemfcs, and reducing the performance and durability of fuel cells, so as to improve the spring characteristics of the gas diffusion layer, improve the bending strength of the carbon substrate, and reduce the effect of gas diffusion layer infiltration into the flow field of the metal bipolar pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

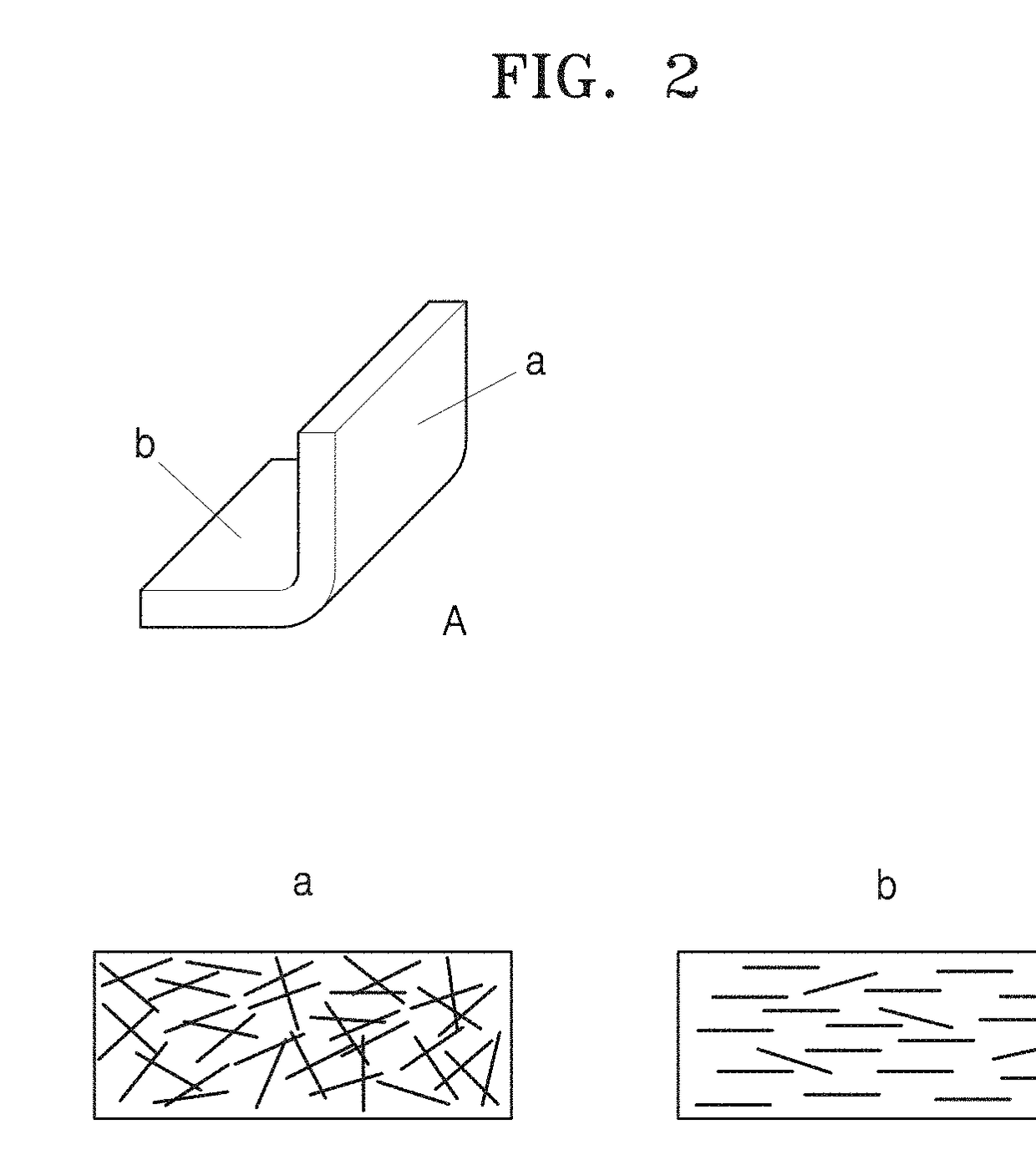

[0072]As raw materials, carbon staple fibers of 90 wt % with respect to a weight of entire fibers were prepared and PVA staple fibers of 10 wt % were prepared, wherein the carbon staple fibers contained carbon by 95%, had a diameter of about 7 μm, a density of about 1.81 g / cc, average lengths of about 6 mm and 12 mm, and a precursor of PAN (here, content amount ratio between the carbon staple fibers of 6 mm length and 12 mm length was 50 / 50). Then, a carbon fiber preweb was manufactured through the carbon preweb manufacturing processes, that is, fiber mixture, dispersion of fibers in water, and deposition on the wire. The carbon fibers dispersed in water were supplied to a paper-making machine via a pump. A supply unit connected to a head box of the paper-making machine had a structure that narrowed toward the head box, and the carbon fibers were arranged in parallel with a direction in which the dispersion liquid flowed. Slits between the wire and the supply unit were adjustable in...

preparation example 2

[0079]A carbon fiber preweb having a MD / TD ratio of 2.0 on the first surface and the second surface was manufactured in the same manner as in preparation example 1, except that there was no section for generating a swirl before the dispersion liquid contacted the wire and a gap between slits on a portion where the dispersion liquid initially contacted the wire was equal to the length of the carbon fiber. After that, the carbon substrate having the characteristics illustrated in Table 1 was obtained through the same processes as in preparation example 1.

example 1

[0080]Two unit carbon substrates manufactured according to preparation example 1 were stacked on each other, compressed, and dried to obtain a stacked unit carbon substrate. The stacking was performed so that a second surface of a first unit carbon substrate at an upper level and a first surface of a second unit carbon substrate at a lower level were in contact with each other.

[0081]The stacking was performed by using a paper-making machine including two head boxes. In a head box of a first zone, a first carbon fiber preweb (unit carbon substrate) was formed and placed on a pickup belt, and then, a second carbon fiber preweb (unit carbon substrate) formed in a head box of a second zone was placed on the pickup belt so that two carbon fiber prewebs can be stacked.

[0082]The dried preweb underwent a heating and pressurizing process at a temperature of about 80° C. to about 150° C. and a pressure of about 1 to about 10 kgf / cm2 and a winding process to obtain the carbon fiber preweb.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com