Trivalent chromium chemical conversion treatment liquid for zinc or zinc alloy base and chemical conversion treatment method using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0039]A chemical conversion treatment liquid was prepared as specified below, and the pH of the liquid was adjusted to 3.7 with ammonia water. Thereafter, the above test specimen was dipped in the chemical conversion treatment liquid at 35° C. for 60 seconds.

(A) 40% chromium nitrate: 5.4 g / L (9 mmol / L in terms of Cr3+ ions and 27 mmol / L in terms of NO3− ions)

(B) Potassium fluorozirconate: 2.0 g / L (7 mmol / L in terms of Zr ions)

(C) Ammonium nitrate: 4.8 g / L (60 mmol / L in terms of NO3− ions)

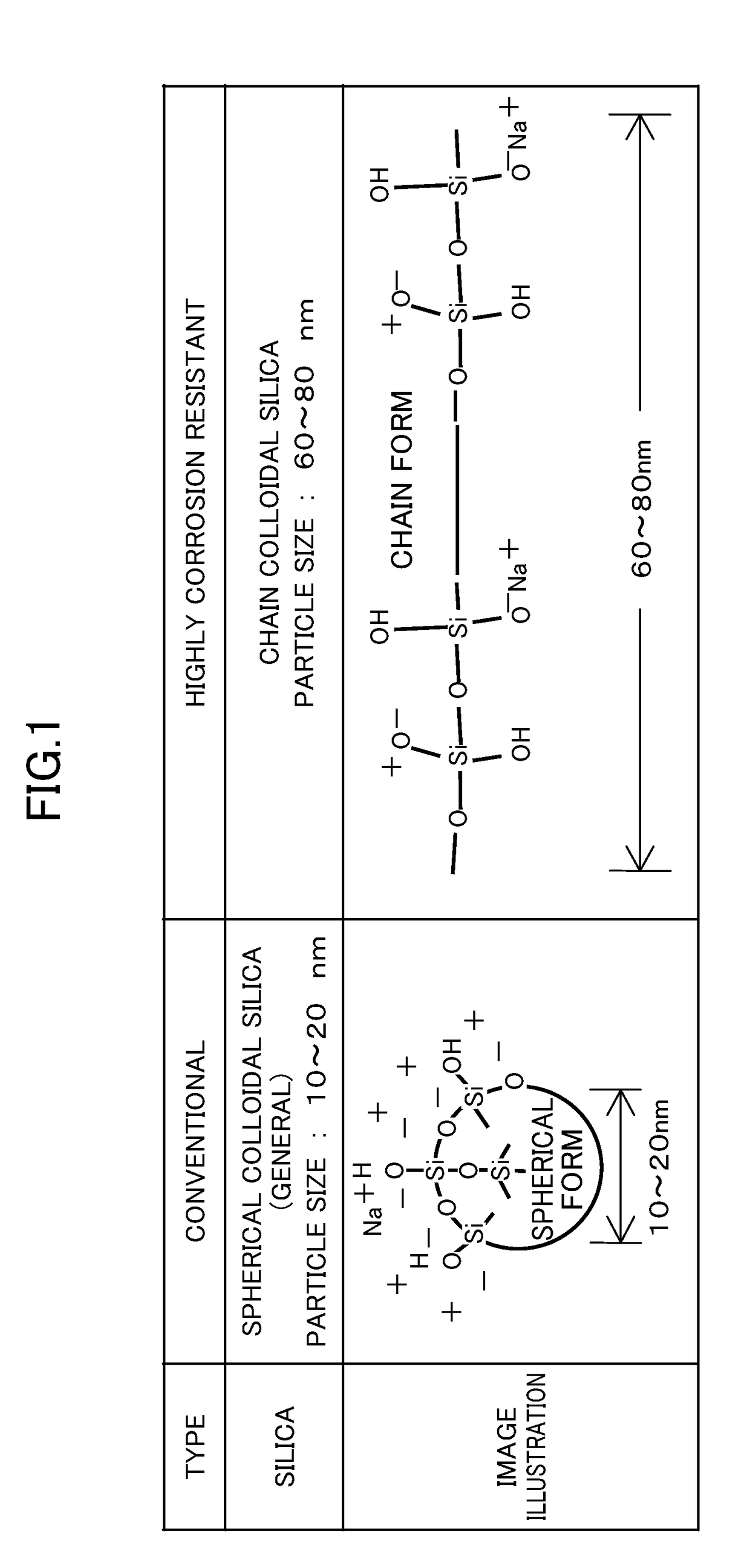

(D) Chain colloidal silica (diameter of 40-100 nm): 20.0 g / L (50 mmol / L)

The residue is water.

example 2

[0040]A chemical conversion treatment liquid was prepared as specified below, and the pH of the liquid was adjusted to 3.5 with ammonia water. Thereafter, the above test specimen was dipped in the chemical conversion treatment liquid at 45° C. for 40 seconds.

(A) 35% chromium chloride: 9.0 g / L (20 mmol / L in terms of Cr3+ ions)

(B) 40% zirconium fluoride: 7.8 g / L (15 mmol / L in terms of Zr ions)

(C) Sodium nitrate: 7.2 g / L (85 mmol / L in terms of NO3− ions)

[0041]Zinc nitrate hexahydrate: 0.75 g / L (5 mmol / L in terms of NO3− ions)

(D) Chain colloidal silica (diameter of 40-100 nm): 40.0 g / L (100 mmol / L)

The residue is water.

example 3

[0042]A chemical conversion treatment liquid was prepared as specified below, and the pH of the liquid was adjusted to 3.5 with ammonia water. Thereafter, the above test specimen was dipped in the chemical conversion treatment liquid at 40° C. for 30 seconds.

(A) 40% chromium sulfate: 8.8 g / L (18 mmol / L in terms of Cr3+ ions)

(B) Ammonium hexafluorozirconate: 2.4 g / L (10 mmol / L in terms of Zr ions)

(C) Ammonium nitrate: 12.0 g / L (150 mmol / L in terms of NO3− ions)

(D) Chain colloidal silica (diameter of 40-100 nm): 64.0 g / L (160 mmol / L)

The residue is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap