Hair-coloring compositions, aerosol products, and methods for coloring hair

a technology of compositions and aerosol products, applied in the direction of hair cosmetics, toilet preparations, pharmaceutical active ingredients, etc., can solve the problems of difficult to achieve dark shades, messy and time-consuming process, and difficulty in producing dark shades, so as to improve the color deposition and intensity of direct dyeing, improve the effect of color deposition and intensity of hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

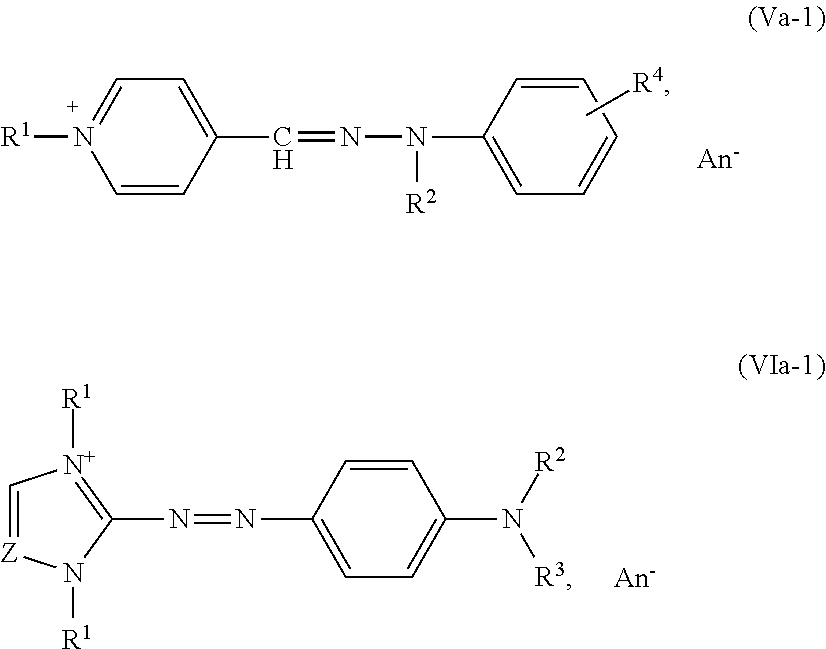

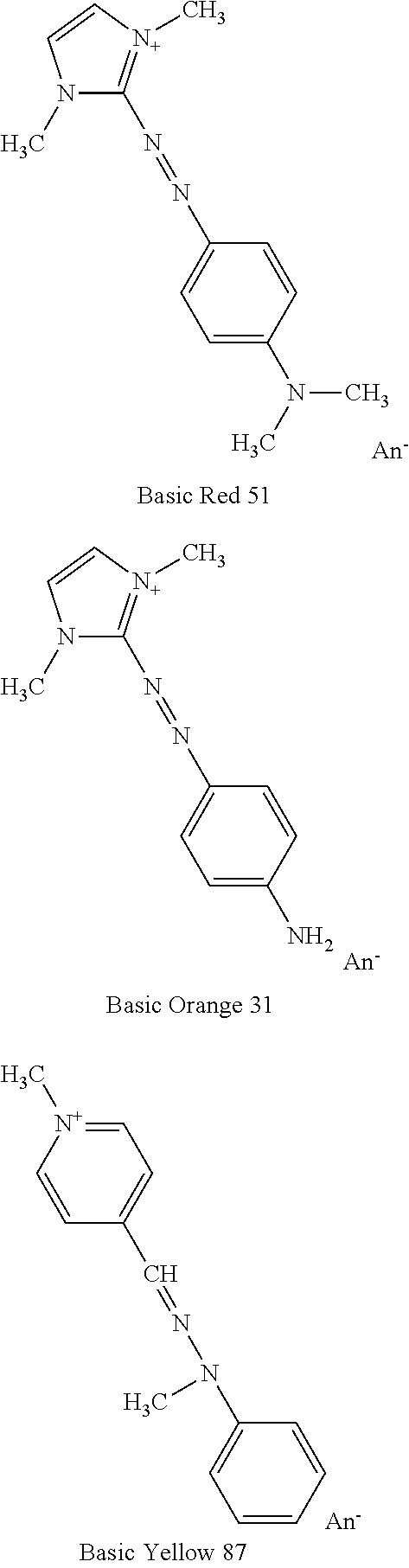

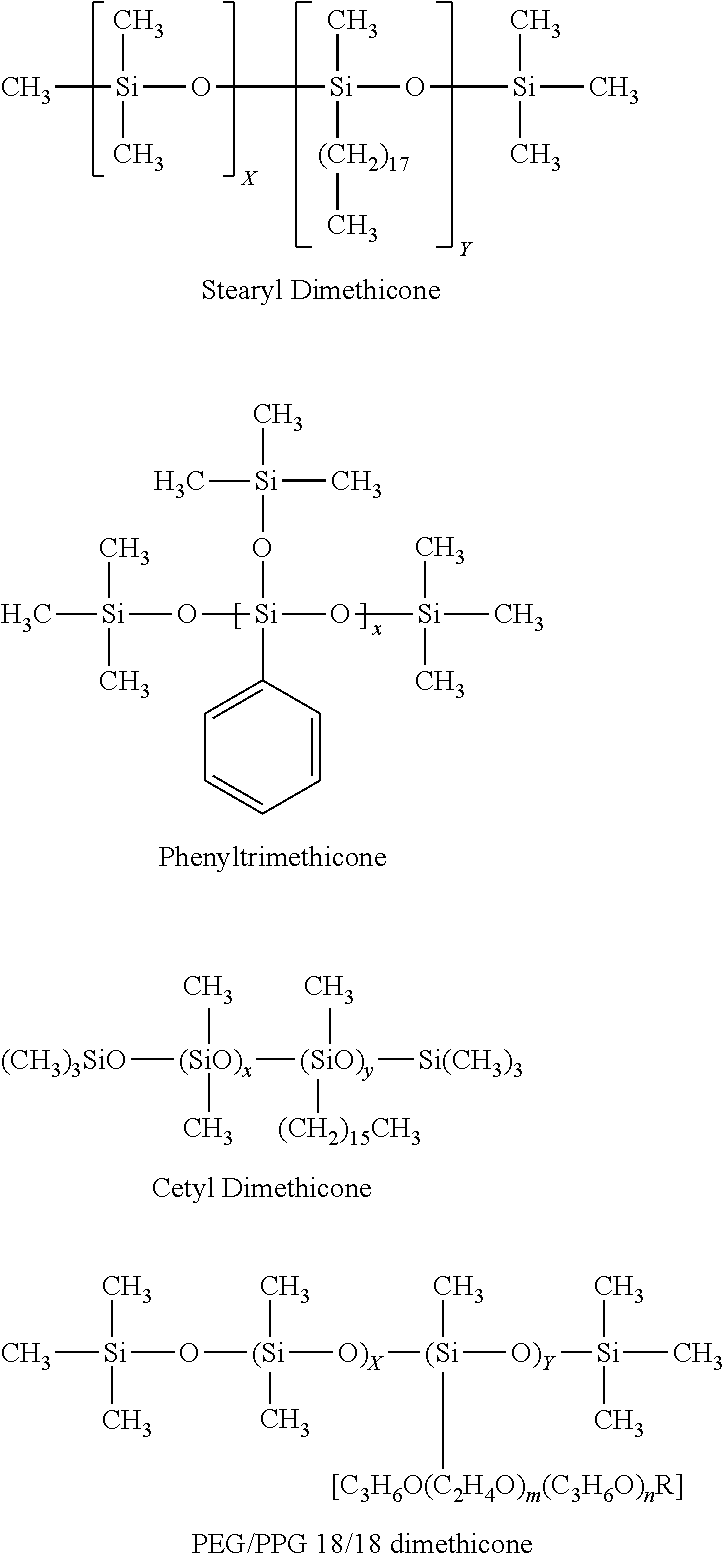

[0288]In certain embodiments, the instant disclosure relates to a hair coloring composition comprising:[0289](a) about 0.01 to about 15 wt. %, preferably about 0.05 to about 10 wt. %, more preferably about 0.1 to about 5 wt. % of at least one direct dye selected from nitro-phenylenediamines, nitro-aminophenols, azo dyes, anthraquinones, triarylmethane dyes, indophenols, and a mixture thereof;[0290](b) about 0.1 to about 25 wt. %, preferably about 1 to about 15 wt. %, more preferably about 1 to about 8 wt. % of at least one nonionic film forming polymer for example, film forming polymers selected from polyalkyloxazolines; vinyl acetate homopolymers; vinyl acetate copolymers; homopolymers and copolymers of acrylic esters; copolymers of acrylonitrile and a nonionic monomer; styrene homopolymers; styrene copolymers (for instance copolymers of styrene and of an alkyl (meth)acrylate; copolymers of styrene, of alkyl methacrylate and of alkyl acrylate; copolymers of styrene and of butadiene...

example 1

Inventive Aerosol Hair-Coloring Products

[0321]

AB(wt. %)(wt. %)INCI USRedRedDirect DyesBASIC RED 51 &≤1≤1BASIC YELLOW 87Nonionic Film FormerVP / VA COPOLYMER2PVP0.3Thickening AgentPOLYACRYLATE-30.20.2(anionic)EthanolALCOHOL DENAT.16.316.3WaterWATER45.647.3SiliconesDIMETHICONE & BIS-0.50.5PEG / PPG-14 / 14DIMETHICONEFillerXYLOSE0.010.01MiscellaneousSALTS, PH≤2≤2ADJUSTERS,BUFFERING AGENT,PRESERVATIVES, ETC.PropellantDIMETHYL ETHER3535

example 2

Influence of Water / Ethanol—Color Uptake

[0322]

CDEFGH(wt. %)(wt. %)(wt. %)(wt. %)(wt. %)(wt. %)INCI USRedRedRedMagenta MagentaMagentaDirect DyesHC BLUE NO. 15 &≤1≤1≤1BASIC RED 51BASIC YELLOW 87 &≤1≤1≤1BASIC RED 51NonionicVP / VA COPOLYMER333333Film FormerThickeningHYDROXYETHYL-0.50.50.50.50.50.5AgentCELLULOSE(nonionic)EthanolALCOHOL DENAT.2537.5502537.550WaterWATER705845715846SiliconeDIMETHICONE &0.80.80.80.80.80.8BIS-PEG / PPG-14 / 14DIMETHICONEFillerXYLOSE0.020.020.020.020.020.02Misc.SALTS, PH≤2≤2≤2≤2≤2≤2ADJUSTERS,BUFFERING AGENT,PRESERVATIVES,ETC.

[0323]Testing was carried out to determine the influence of water and ethanol on color uptake. Compositions C, D, and E are red coloring compositions (juice) that are identical except for the amounts of ethanol and water. Composition C includes 25 wt. % of ethanol (and 70 wt. % of water), Composition D includes 37.% wt. % of ethanol (and 58 wt. % of water), and composition E includes 50 wt. % of ethanol (and 45 wt. % of water). Compositions F, G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com