Super-hydrophilic surface treatment method of filtration medium, super-hydrophilic filter for oil-water separation and method of fabricating the same

a technology of superhydrophilicity and surface treatment, which is applied in the direction of filtration separation, membranes, separation processes, etc., can solve the problems of poor treatment efficiency, and easy loss of hydrophilicity of hydrophilic surface body, and achieves easy fabrication, excellent superhydrophilicity and superoleophobicity in water, and the effect of easy surface treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

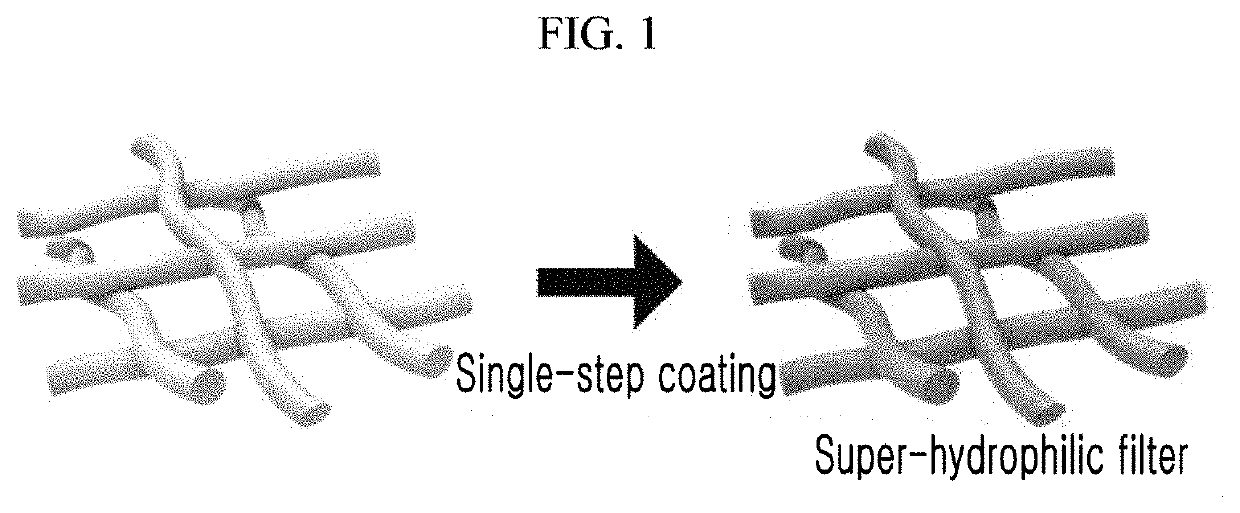

on of Super-Hydrophilic Filter According to Single-Step

[0072]Coating Process

[0073]1-1: Preparation of Filtration Filter

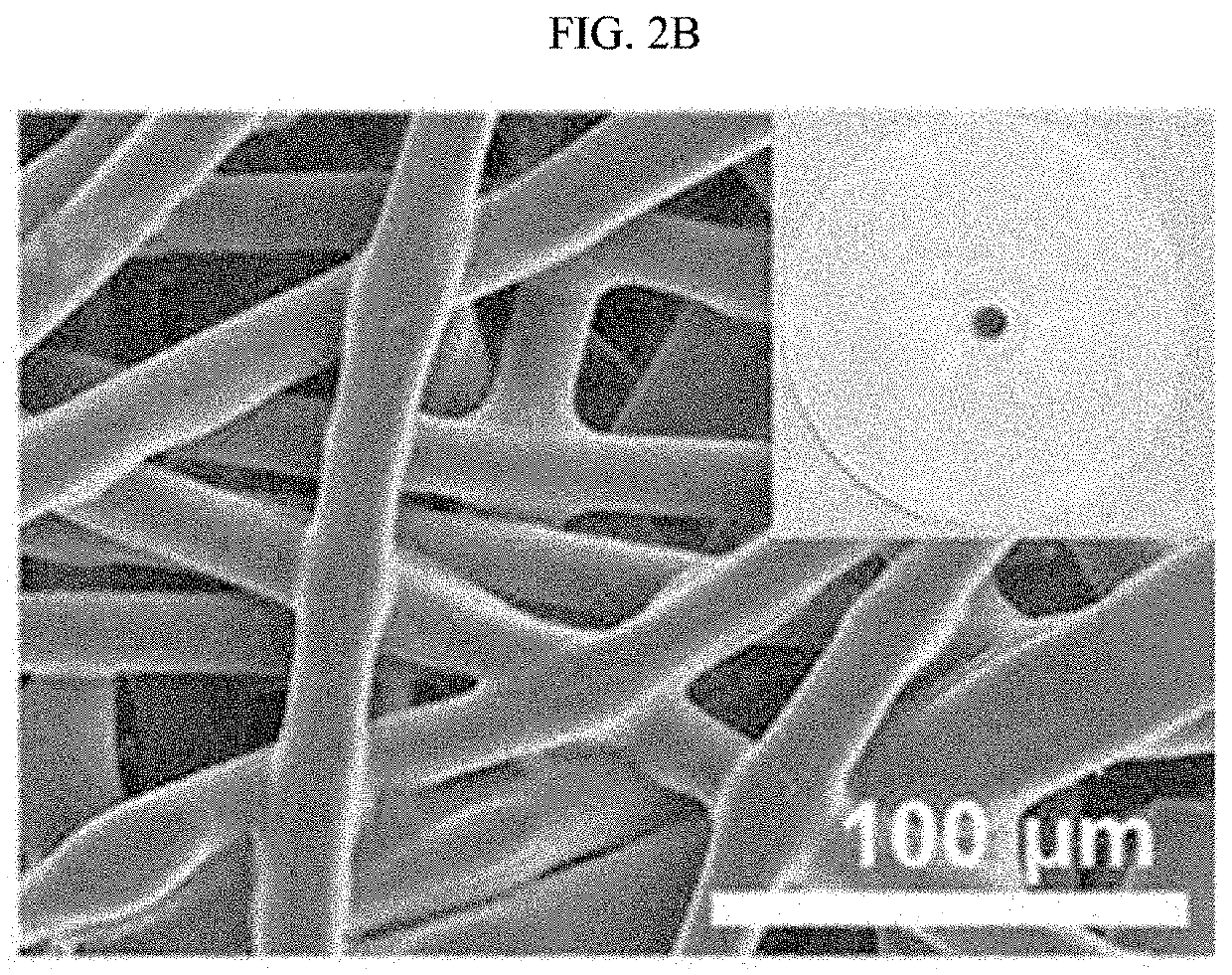

[0074]To fabricate a super-hydrophilic filter, a commercially available polyethylene (PE) filter (a membrane filter having a diameter of 47 mm and a nominal pore size of 10 μm; Pall Life Science (USA)) which was not surface-treated was prepared. An SEM photograph of the polyethylene filter before surface treatment is shown in FIG. 2B. Here, polymer fibers and pores formed by cross-linking the polymer fibers are shown. Such a general commercial PE filter has hydrophobicity due to the presence of a methyl group having a low surface tension with respect to the microsized fibers.

[0075]1-2: Formation of Hydrophilic Coating Layer

[0076]The prepared polyethylene (PE) filter was immersed in an aqueous ethanol solution at 20° C. for 10 seconds, and then immersed in a mixed solution including bis-acrylamide (N,N-methylenebisacrylamide) as a cross-linking agent and ammonium per...

example 2

n of Characteristics of Polymer Filters During Formation of Coating Layer

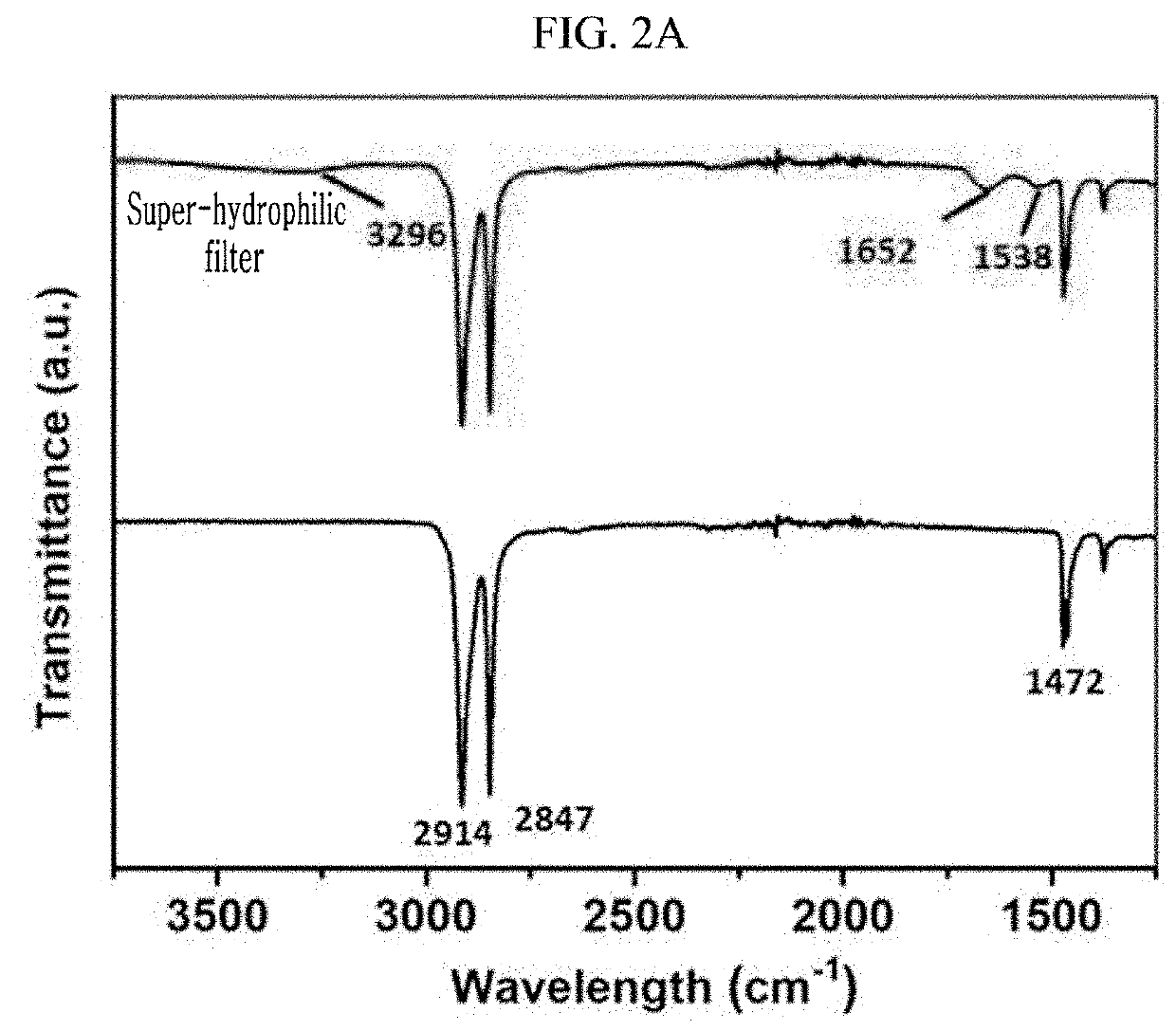

[0078]2-1: Spectroscopic Analysis of Filter

[0079]For a conventional polyethylene (PE) filter and a filter composed of polyethylene fibers having a surface product obtained by the process, it was evaluated whether a functional group was formed using Fourier transform infrared spectroscopy.

[0080]Based on the results of evaluating the formation of the functional group using Fourier transform infrared spectroscopy as obtained in FIG. 2A, the conventional untreated PE filter had characteristic peaks at 1,472, 2,847, and 2,914 cm−1, as widely known in the art. After the single-step coating, the characteristic peaks were further observed at 1,538, 1,652, and 3,296 cm−1, indicating the hydrophilic functional groups, for example, C═O, C═O, and N—H bonds.

[0081]2-2: Evaluation of Hydrophilicity of Filter

[0082]A polymer base, a metal base, and a super-hydrophobic base were subjected to the coating method according to the p...

example 3

on of Large Super-Hydrophilic Filter

[0087]A photograph of a large super-hydrophilic filter with a size of 400 mm×1,000 mm fabricated by the surface treatment process according to the present invention is shown in FIG. 5. The large super-hydrophilic filter was fabricated using a stainless steel mesh (TWP Inc.) as the base, and a mesh base with a length of 400 mm and a width of 1,000 mm was identical to the stainless steel mesh used in Example 2. Because the surface treatment process was applied to a simple immersion method as a single coating process, a large super-hydrophilic filter was able to be easily fabricated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com