Low lead release plumbing components made of copper based alloys containing lead, and a method for obtaining the same

a technology of low lead release and plumbing components, which is applied in the direction of water mains, decorative surface effects, decorative arts, etc., can solve the problems of heavy metals that are highly polluted and toxic to human health, difficult to be coated properly, and released into the environment, and achieves high environmental safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Copper Alloys

Five not etched samples identified as A, B, C, D, and E, are obtained from 5.15 mm diameter drawn annealed wire in CuZn37Pb3 (according to CEN denomination). Sample A, examined by a scanning electron microscope (SEM) gave the results shown in FIGS. 1 and 2. Thereafter, samples B, C, D and E were treated following the procedures described in Table 1.

After treatment, rinsing in water and drying without hot air, samples B, C, D and E were examined by SEM technique giving the results reported in FIGS. 3 to 6, respectively. From these micrographics, it appears that methanesulfonic acid and acetic acid are effective in selectively dissolving the surface smeared lead, while citric acid is effective if used in conjunction with an oxidizing agent, as e.g. hydrogen peroxide.

example 2

Copper Alloys

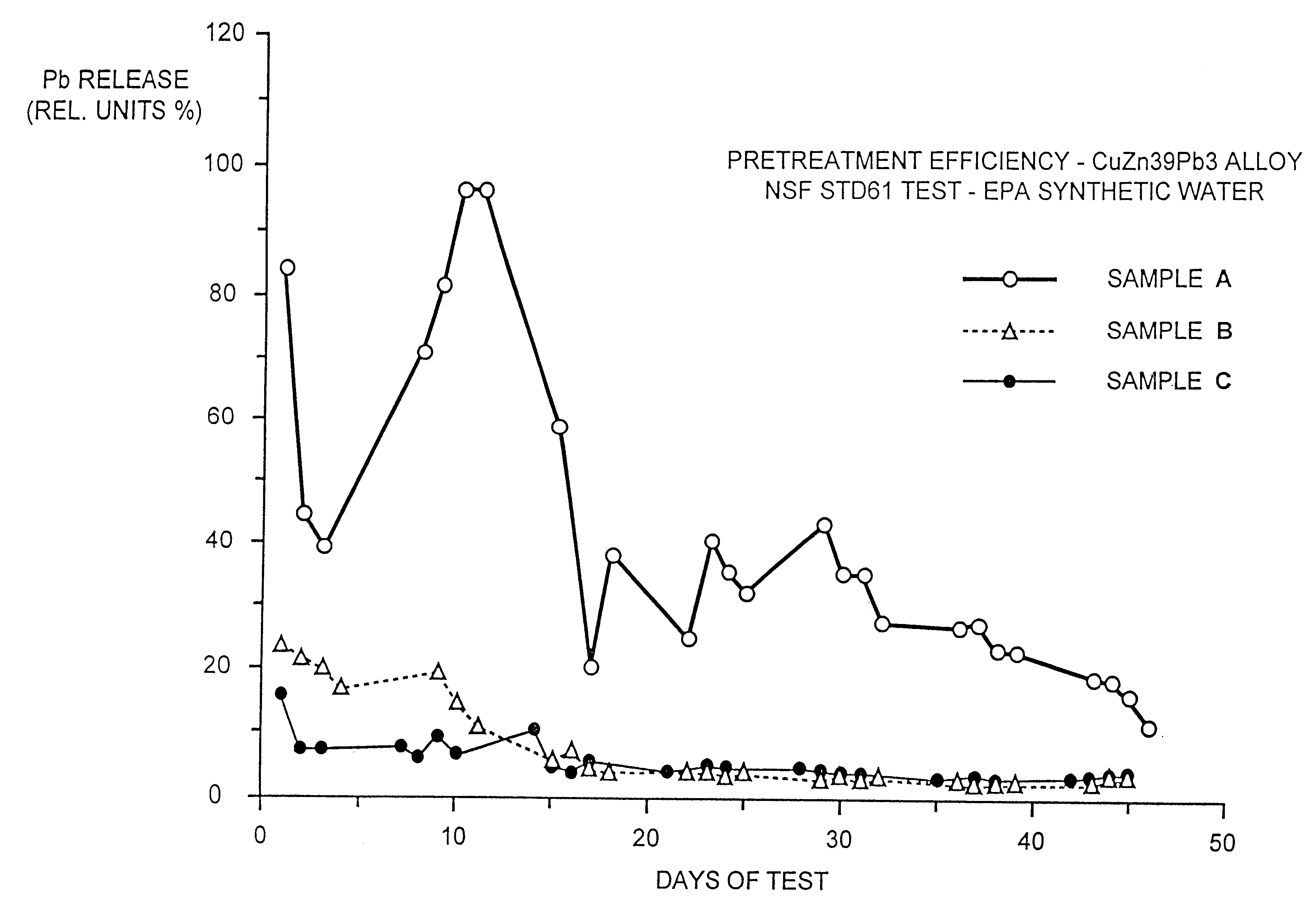

Three samples, identified as A, B and C, were taken from the same bar in CuZn39Pb3, extruded and drawn to 50 mm diameter, normally available in commerce. All samples were drilled and machined with lathe turning operation, under the same working conditions, in order to obtain 100 mm high cylinders with internal diameter of 36 mm and external diameter of 50 mm All samples were degreased and washed with tap water, Sample C was subjected to lead selective dissolution by:

1--immersion in solution "a": 0.1 M sulfamic acid (pH 1.25), at 40.degree. C. for twenty minutes;

2--washing with water;

3--immersion in solution "b": 0.1 M NaOH (pH 12.7) at 40.degree. C. for ten minutes;

4--washing with water and hot air-drying.

The overall amount of lead and copper recovered from solutions "a" and "b" per square decimeter of treated surface came to 11.4 mg and 0.1 mg, respectively. Sample B was subjected to steps (1) and (2) only of the aforedescribed procedure, then dried with hot air.

Inner ...

example 3

Copper Alloys

Four samples A, B, C and D from the same bar in brass CuZn39Pb2 brass, normally extruded and drawn to 50 mm diameter, normally available in commerce, were drilled and machined with lathe turning operation, under the same working conditions, obtaining 100 mm high cylinders, with internal diameter of 36 mm and 50 mm external diameter. All samples were degreased and washed with tap water.

Samples A and B were subjected to lead-selective dissolution by:

1--immersion in solution "a": 0.1 M fluoboric acid at 40.degree. C. for twenty minutes;

2--washing with water;

3--immersion in solution "b": 0.1 M NaOH at 20.degree. C. for ten minutes;

4--washing with water and hot air-drying.

The overall amount of lead and copper recovered from solutions "a" and "b" per square decimeter of treated surface came to 7.3 mg and 0.1 mg, respectively. Sample B was subjected only to steps (1) and (2) of the aforedescribed procedure, then dried with hot air.

All samples were then subjected to a test for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com