n-Propylethoxysiloxanes, their preparation and use

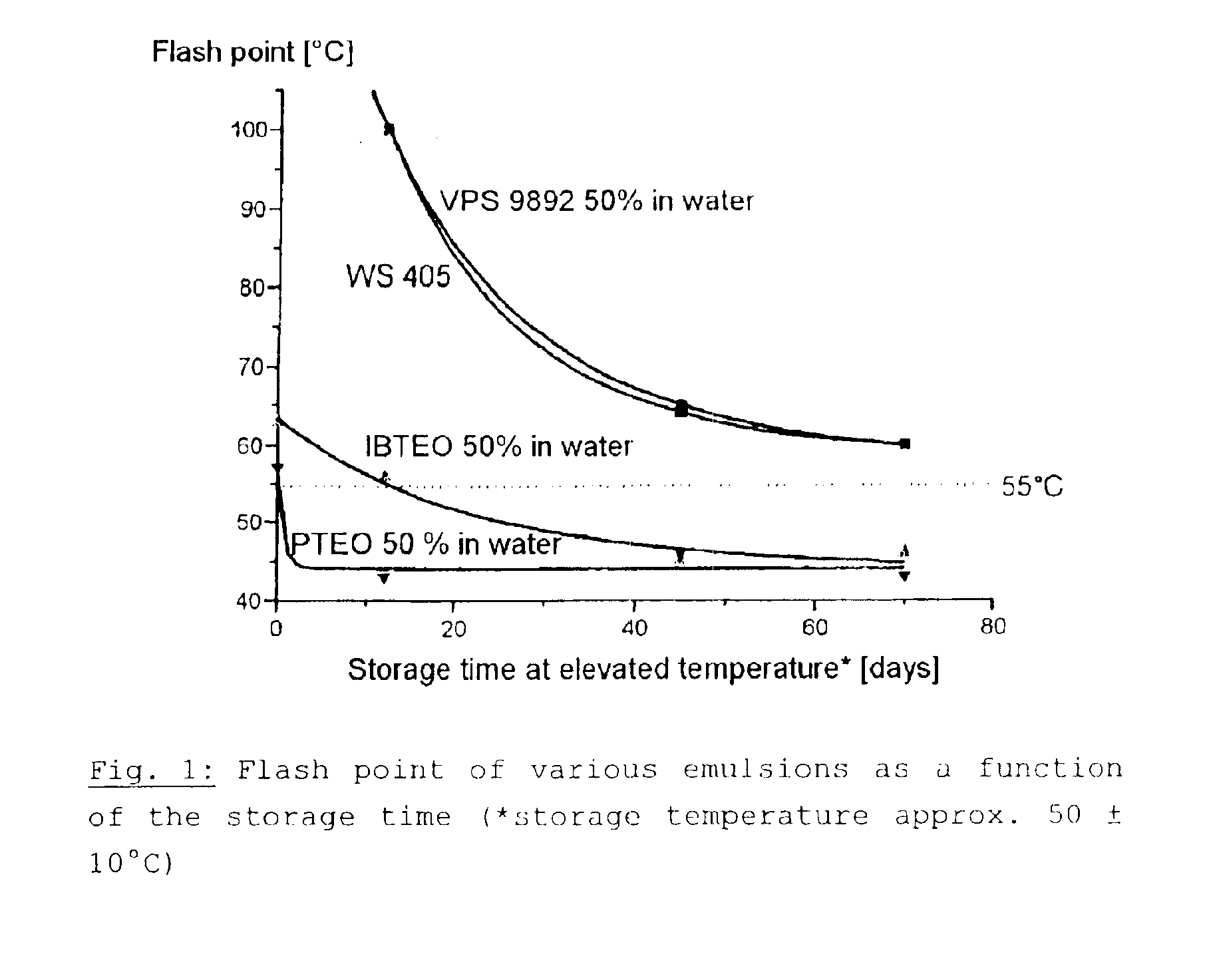

a technology of n-propylethoxysiloxanes and n-propylethoxysiloxanes, which is applied in the field of n-propylethoxysiloxanes, can solve the problems of poor penetration behavior of active substances into substrates, discoloration of substrate surfaces, and at least unwanted sheen or oily appearance of substrates, and achieves high flash point, good application properties, and high effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

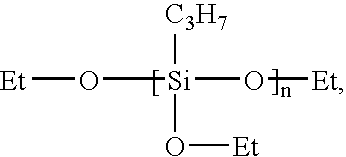

[0066]Preparation of a Mixture of Oligomeric n-propylsiloxanes From n-propyltriethoxysilane and Water (0.8 mol of Water per Mole of Si) Product Designation VPS 9892

[0067]A 2 liter jacketed stirring apparatus is charged with n-propyltriethoxysilane (PTEO) and this initial charge is heated to approximately 80° C. At this temperature, a mixture of ethanol, water and hydrochloric acid is added dropwise by a dropping funnel. The entire reaction mixture is subsequently boiled at reflux for four hours. Thereafter, the ethanol used and the ethanol released during the hydrolysis are removed by distillation, first at ambient pressure and then in vacuo. The liquid remaining at the bottom is VPS 9892.

Amounts used:PTEO1,120.5gWater76.5gEthanol321gHCl (32% by weight in water)1.5gProduct isolated:VPS 9892 (yield: 97% of theory)780.81g

example 2

[0068]Preparation of a Mixture of Oligomeric n-propylsiloxanes (Hydrolyzed With 0.6 Mol of Water Per Mole of Si)

[0069]A 4 literjacketed stirring apparatus is charged with n-propyltriethoxysilane (PTEO) and this initial charge is heated to approximately 80° C. At this temperature, a mixture of ethanol, water and hydrochloric acid is added dropwise by a dropping funnel. The entire reaction mixture is subsequently boiled at reflux for four hours. Thereafter, the ethanol used and the ethanol released during the hydrolysis are removed by distillation, first at ambient pressure and then in vacuo. The liquid remaining at the bottom is the desired propylsiloxane.

Amounts used:PTEO1,442.7gWater75.6gEthanol1,518gHCl (32% by weight in water)1.58gProduct isolated:Propylsiloxane (yield: 91% of theory)1,030.9g

[0070]Composition by GPC (gel permeation chromatography). By means of GPC, mixtures of different molecular size can be separated. By comparison with a standard, it is possible to determine th...

example 4

[0074]Penetration Behavior of VPS 9892 on Lime Sandstone

[0075]A lime sandstone specimen (sawn, commercially customary lime sandstone in blocks 5×5×5 cm, dried in a forced-air drying cabinet at 60° C. to constant weight and then cooled to room temperature in a laboratory for about 3 hours) is immersed in VPS 9892 for 2×5 seconds. Between the impregnating steps, the specimen is allowed to drip-dry for 30 seconds. Following the second impregnation, excess impregnant is dabbed off with an absorbent cloth. Subsequently, the test specimen is left to react at room temperature for about 1 week in the laboratory. Thereafter, the test specimen is split into 2 halves using a hammer and chisel. The fresh fracture surfaces are treated with an aqueous dye solution (Azorubin S). Hydrophilic regions are stained red, hydrophobic regions remain colorless, since they are not wetted by the aqueous ink. The uncolored regions show the depth of penetration. This is measured at different regions by means o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com