Scanning electron microscope

a scanning electron microscope and electron microscope technology, applied in the field of scanning electron microscope, can solve the problems of reduced volume, eventual change in the shape of the circuit pattern, dark image, etc., and achieve the effect of improving throughput and high-visibility imag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

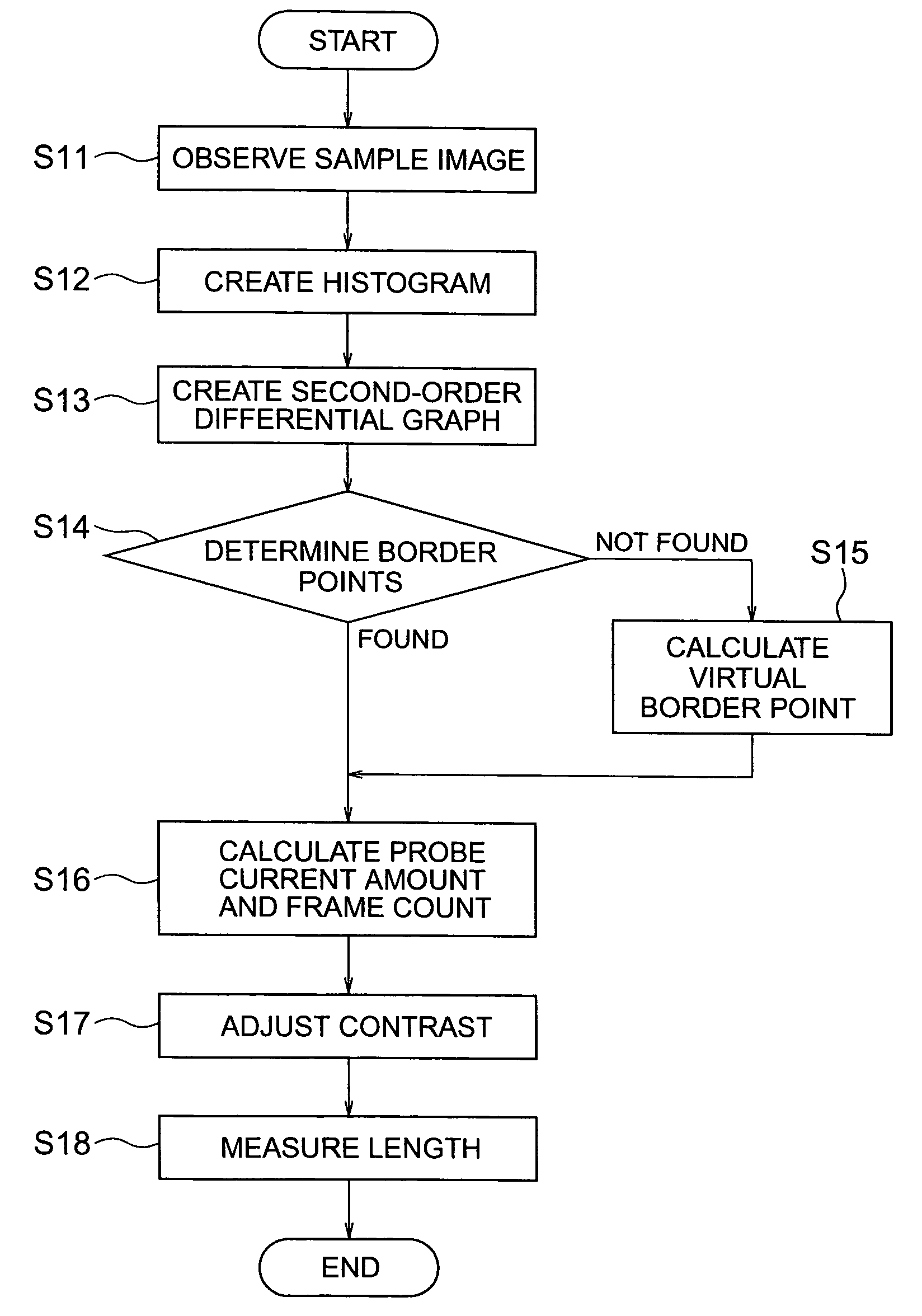

[0029]In the following, embodiments of the present invention will be described with reference to the accompanying drawings.

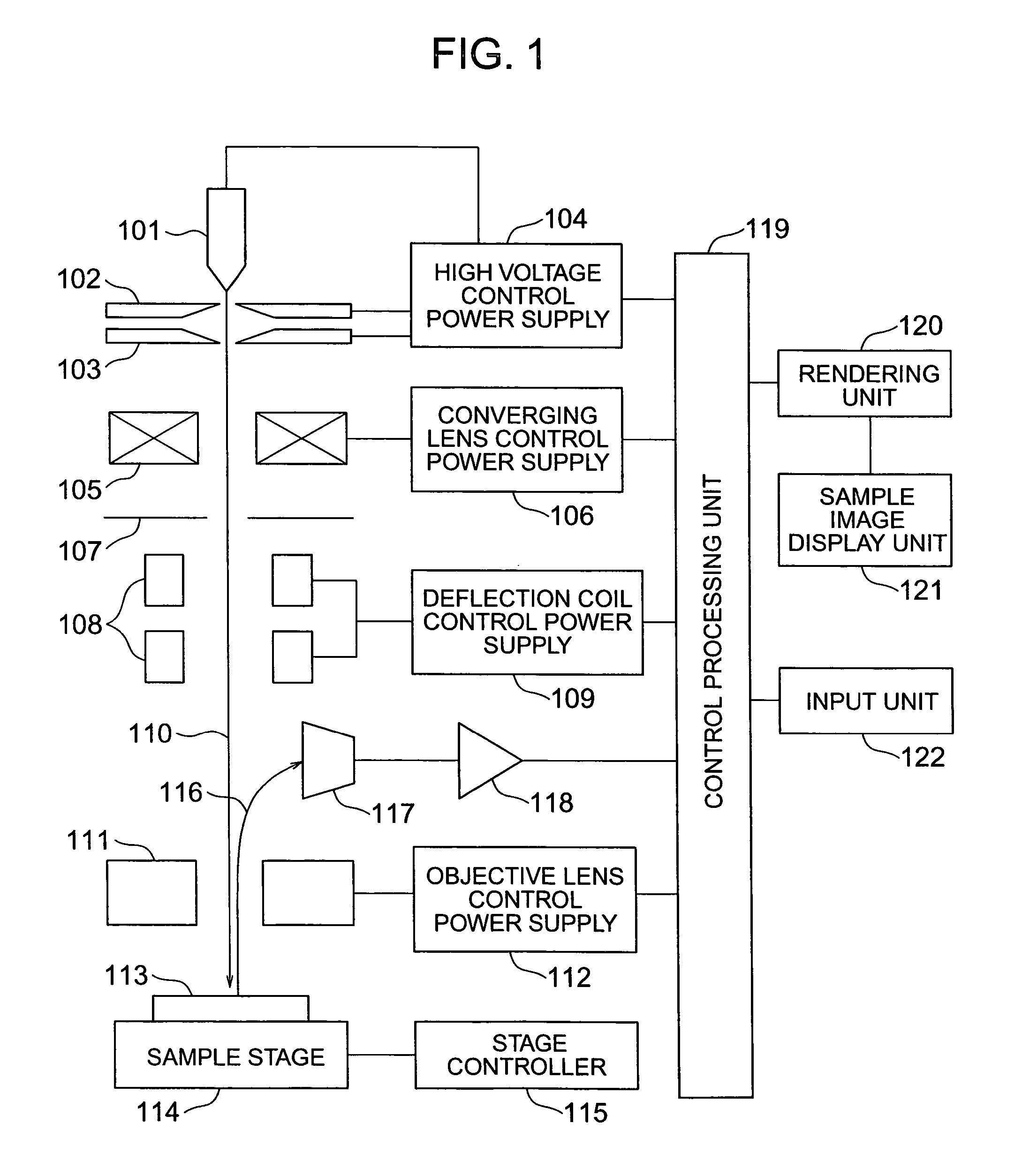

[0030]FIG. 1 is a block diagram generally illustrating a scanning electron microscope according to the present invention. A voltage is applied between a cathode 101 and a first anode 102 by a high voltage control power supply 104 which is controlled by a control processing unit 119 to draw a predetermined emission current from the cathode 101. Since an accelerating voltage is applied between the cathode 101 and a second anode 103 by the high voltage control power supply 104 controlled by the control processing unit 119, a primary electron beam 110 emitted from the cathode 101 is accelerated to travel to a subsequent lens system. The primary electron beam 110 is converged by a convergence lens 105 controlled by a convergence lens control power supply 106, and an unnecessary region of the primary electron beam 110 is removed by an aperture plate 107. Then, the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| scanning electron microscope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com