Composite pigment original, composite pigment, process for producing ink composition, and ink composition

a composite pigment and pigment technology, applied in the field of composite pigments and pigment originals, can solve the problems of deterioration of dispersed state, low luster of metal powders and the like, and restricted use, and achieve excellent quality, enhanced long-term storage, and facilitated arbitrary coloration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Substrate Sheet

[0129]On a 100 μm-thick PET film, a coating solution having the following composition was coated by spin coating and dried to form a resin layer.

Coating Solution for Resin Layer:

[0130]

PVA (polyvinyl alcohol, average3.3 wt %molecular weight: 10,000, saponificationdegree: 80%)Glycerin1.7 wt %Ion exchanged waterbalance

Resin Layer Coating Conditions:

[0131]Coating conditions: Rotated at 500 rpm for 5 seconds and then rotated at 2,000 rpm for 30 seconds.

[0132]Drying conditions: 100° C., 5 minutes.

[0133]The thickness of the resin layer formed under these conditions was 10 μm.

Formation of Silicon Oxide Layer

[0134]On the thus-processed PET film, a coating solution having the following composition was coated by spin coating and baked to form a silicon oxide layer.

Coating Solution for Silicon Oxide Layer:

[0135]

HAS-6 (produced by Colcoat Co., Ltd.) 10 wt %Ethanol42.5 wt %2-Ethoxyethanol47.5 wt %

Silicon Oxide Layer Coating Conditions:

[0136]Coating conditions: Rotat...

example 2

Preparation of Substrate Sheet

[0149]A resin layer was formed in the same manner as in Example 1.

Formation of Silicon Oxide Layer

[0150]On the PET film processed as above, a silicon oxide layer was formed in the same manner as in Example 1.

Formation of Coloring Material Layer

[0151]A coating solution for forming a coloring material layer having the following composition was prepared as follows.

[0152]A coloring material, a dispersant and ion exchanged water were mixed and then dispersed for 2 hours together with glass beads (diameter: 1.7 mm, in an amount 1.5 times (by weight) the mixture) in a sand mill (manufactured by Yasukawa Seisakusho). Thereafter, glass beads were removed and a coating solution for forming a coloring material layer was obtained.

[0153]

C.I. Pigment Yellow 110 (coloring15.0 wt %material)Styrene-acrylic acid copolymer ammonium 5.0 wt %salt (dispersant, molecular weight:10,000)Glycerin 5.0 wt %Ion exchanged waterbalance

[0154]The coating solution prepared was coated on...

example 3

Aqueous Ink Composition for Inkjet Recording

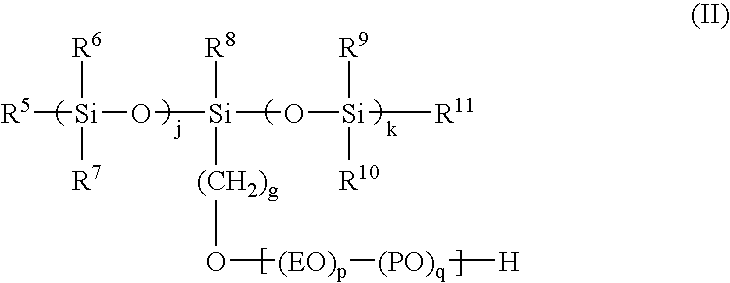

[0168]Solvents and various additives except for a composite aluminum pigment in the blending components shown below were mixed and dissolved to prepare an aqueous dispersion medium for ink, and the composite pigment original obtained in Example 2 was immersed in the prepared aqueous dispersion medium for ink. Then, separation, size-reduction and dispersion of the composite pigment original were performed at the same time by using an ultrasonic disperser to obtain an aqueous ink composition for inkjet recording having a composite pigment content of 15.0 wt %.

Ink Composition 1:

[0169]

Composite aluminum pigment15.0 wt %Styrene-acrylic acid copolymer ammonium 5.0 wt %salt (dispersant, molecular weight:10,000)Glycerin 10 wt %Surfynol 465 (nonionic surfactant, 1.0 wt %produced by Air Product and Chemicals,Inc.)Dipropylene glycol monomethyl ether10.0 wt %Triethanolamine 1.0 wt %HS-500 (sugar alcohol, produced by 2.0 wt %Hayashibara Biochemical La...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com