Two-stage single phase bi-directional PWM power converter with DC link capacitor reduction

a power converter and dc link technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of reducing the potential reducing the power density of the converter, and substantial voltage ripple voltage on the dc side of the converter, so as to reduce the dc link capacitance and improve the power density. , the effect of low dc ripple voltag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

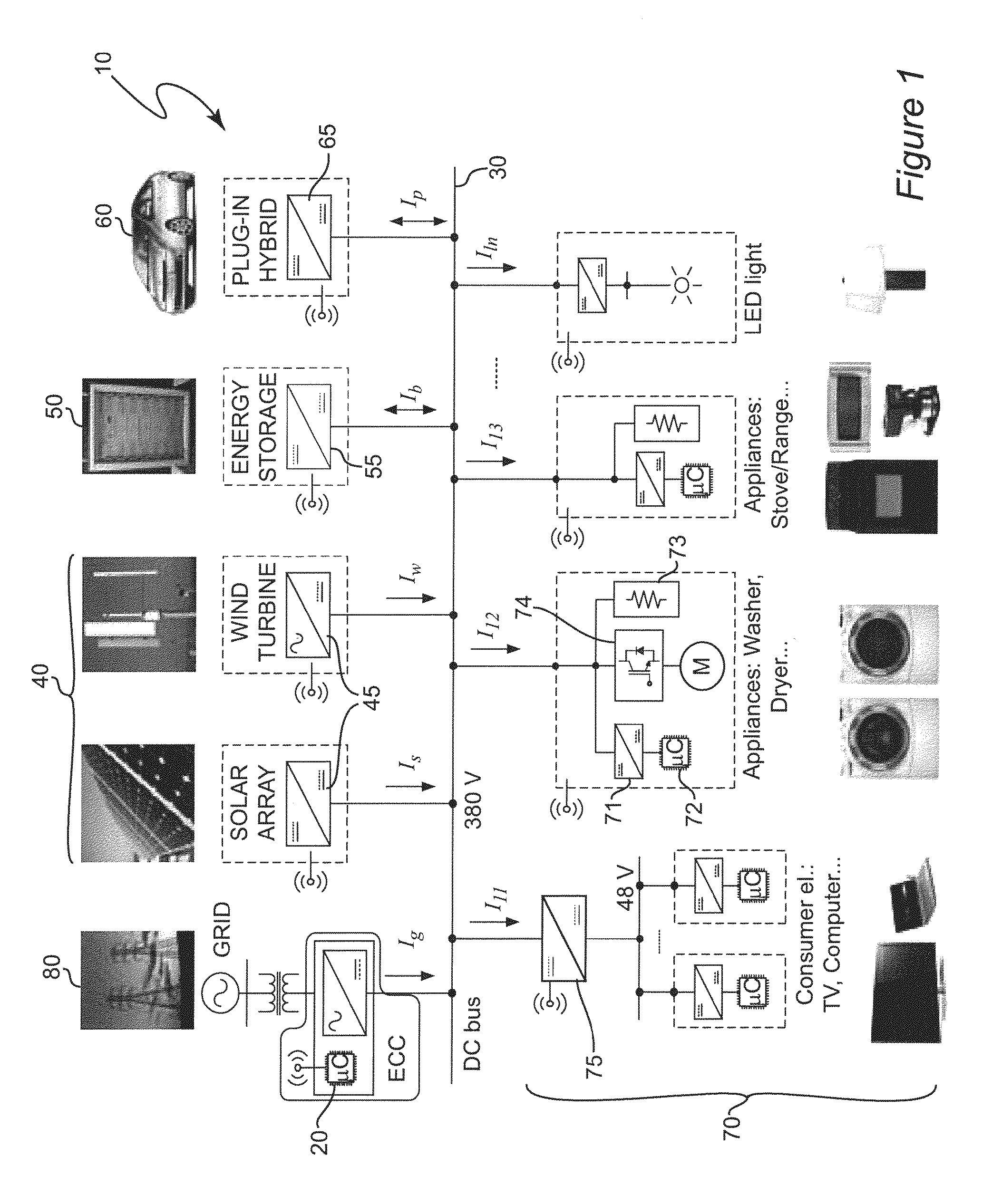

[0036]Referring now to the drawings, and more particularly to FIG. 1, there is shown, in highly schematic form, a generalized depiction of a DC nanogrid 10 which is an exemplary environment for application of the invention, generally depicted at 20. It should be understood that FIG. 1 is arranged to facilitate an understanding of the application of the invention and no portion of FIG. 1 is admitted to be prior art in regard to the present invention.

[0037]Essentially, a DC nanogrid is a power distribution grid which is generally very limited in geographic extent (e.g. limited to a building or one or a limited number of residences or a vehicle such as a ship or aircraft) in which power is distributed over DC bus 30 at a nominal DC voltage of 380 volts although other nominal voltages can be employed and, in any case, the nominal design voltage is unimportant to the successful practice of the invention. It should be understood that DC bus 30 can also be embodied as a plurality of DC bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com