Manufacturing method of organic semiconductor film, organic semiconductor film, thin film transistor, active matrix device, electro-optical device, and electronic device

a manufacturing method and organic semiconductor technology, applied in semiconductor devices, solid-state devices, electrical devices, etc., can solve the problems of remarkably decreasing productivity and yield of organic semiconductor films, low stability of organic semiconductor materials used in liquid phase processes, and effective prevention of variation in properties. , the effect of preventing involuntary variation in properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

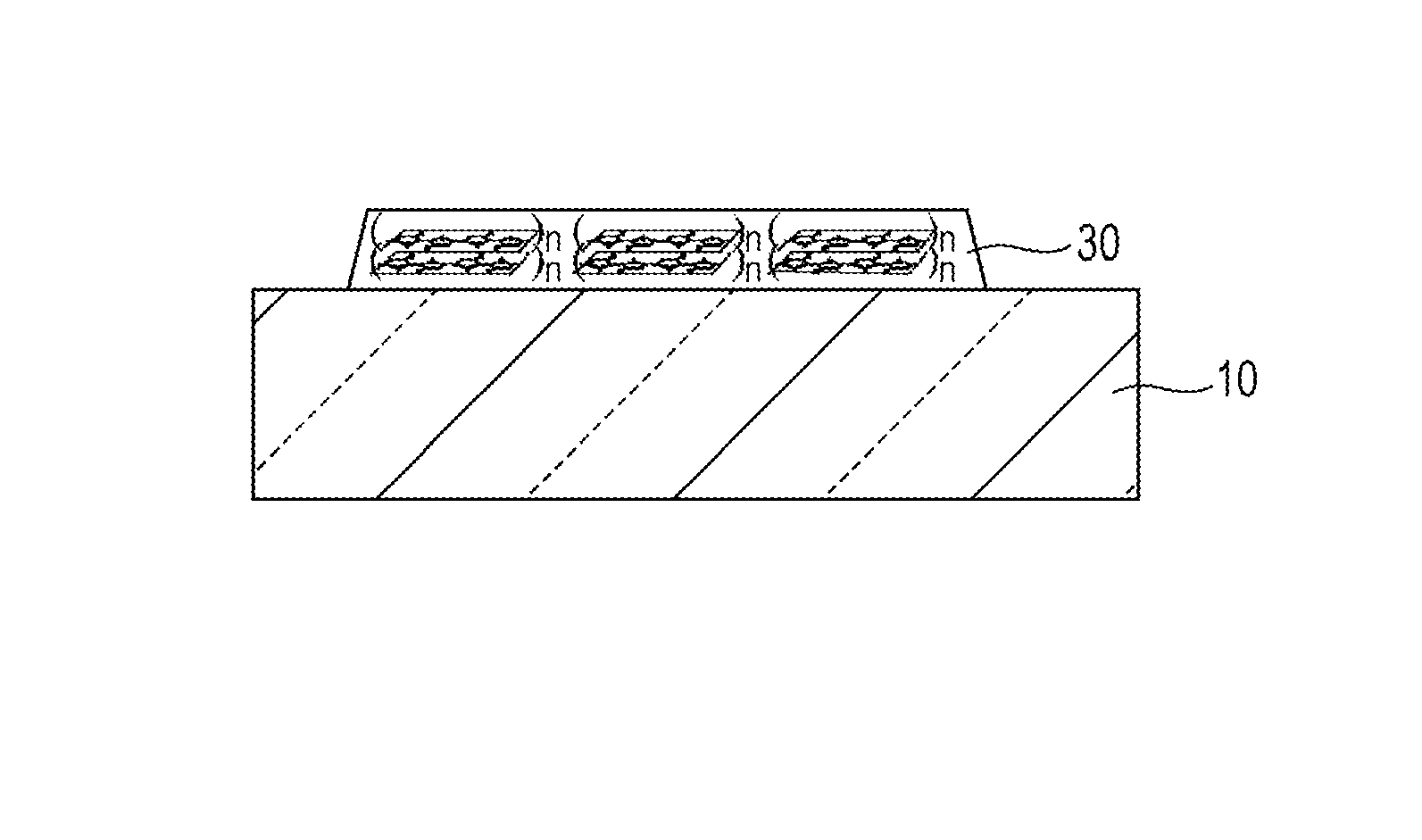

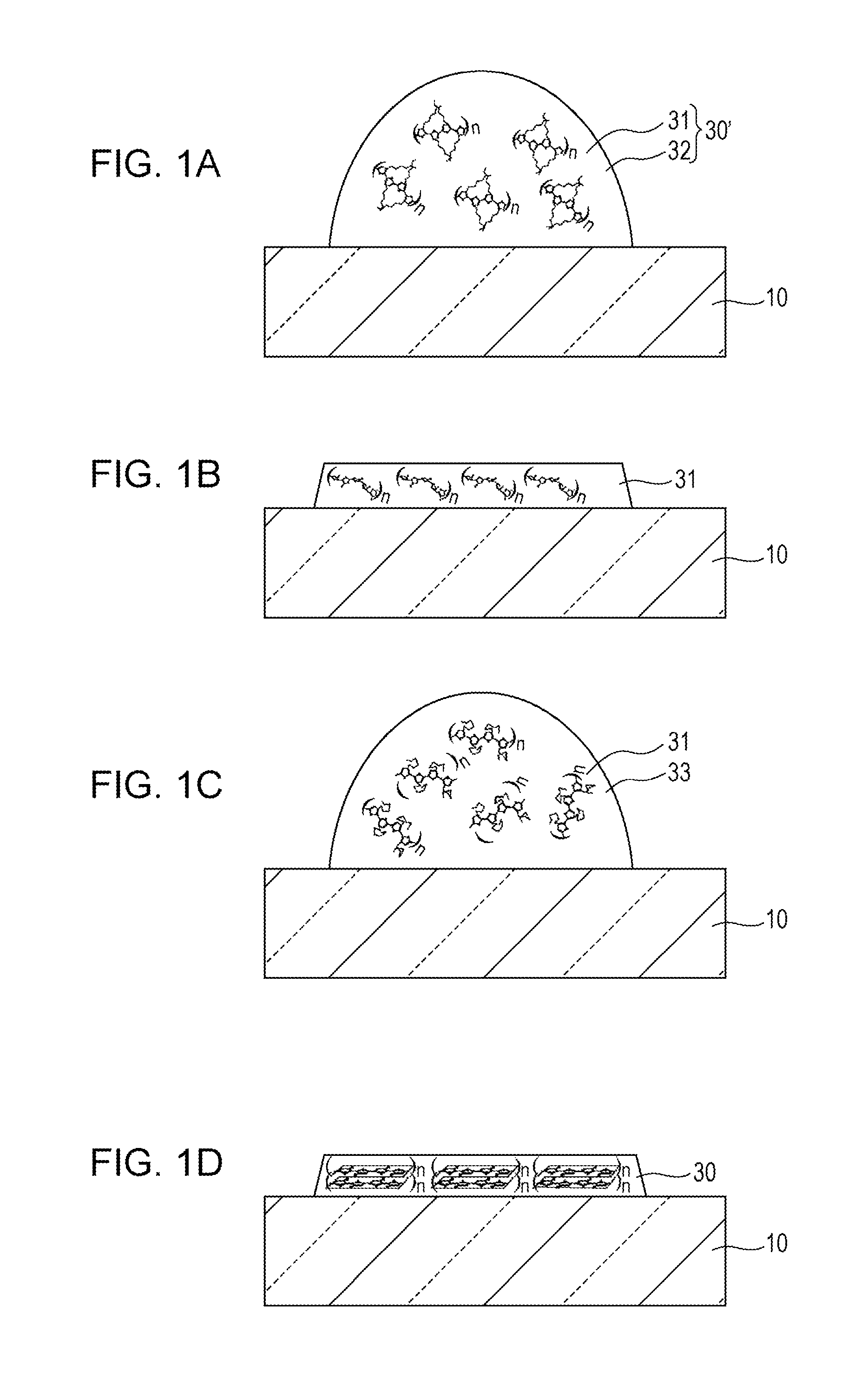

Method used

Image

Examples

example 1

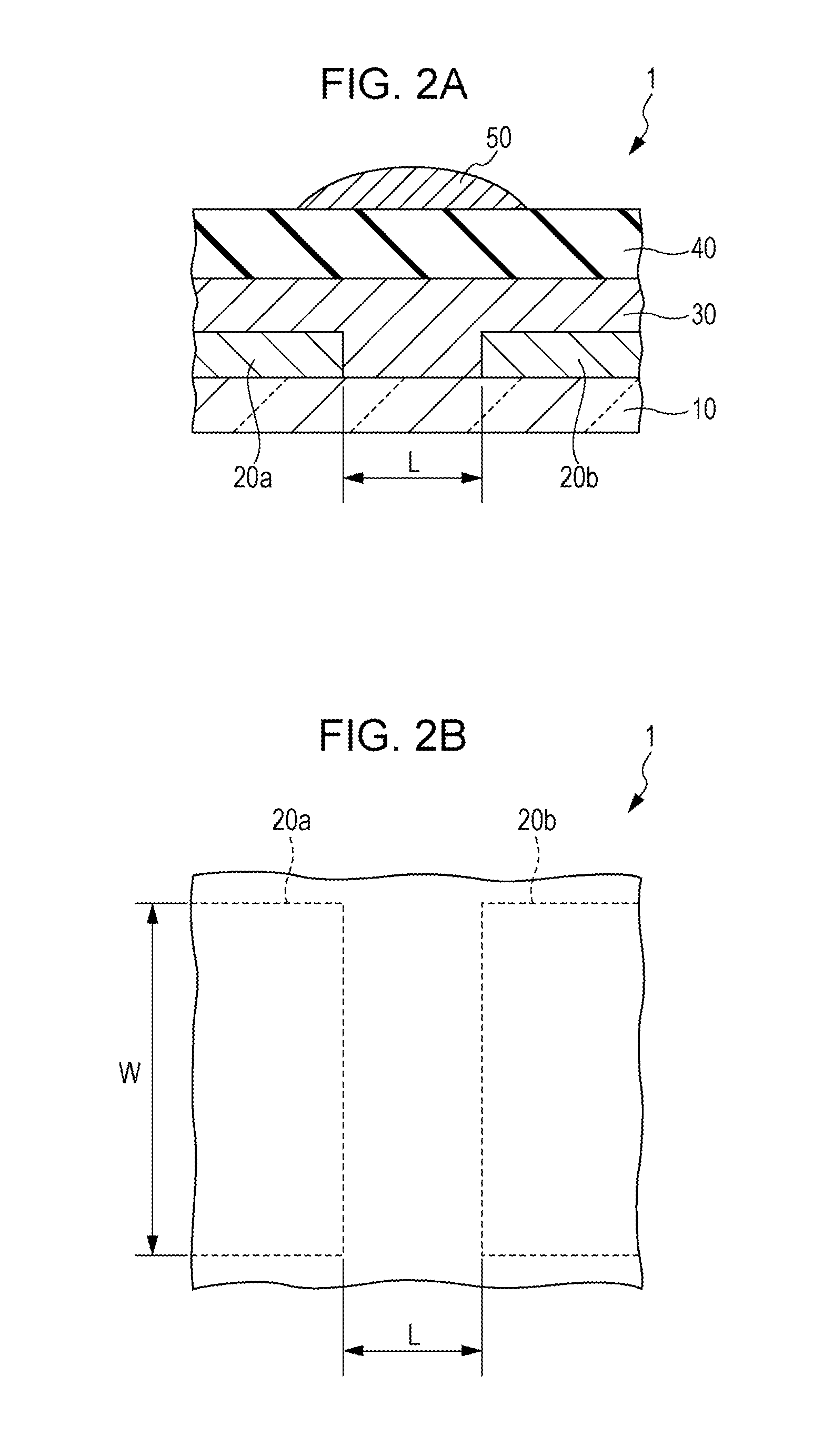

1. Source Electrode and Drain Electrode Forming Step

[0200]First, a plastic substrate was prepared, and a degreasing treatment was performed with respect to a surface using ethanol.

[0201]Gold was vapor deposited on the plastic substrate, and thus a source electrode and a drain electrode were formed. After forming the source electrode and the drain electrode, the plastic substrate on which the source electrode and the drain electrode were formed was immersed in isopropyl alcohol, and was subjected to ultrasonic cleaning for 5 minutes. After the cleaning, the substrate was dried at 60° C. for 10 minutes.

2. Liquid Composition Applying Step

[0202]Next, a liquid composition in which poly(3-hexyl thiophene) (P3HT) (a weight-average molecular weight: 30000) as an organic semiconductor material was dispersed in xylene as a first solvent was applied onto the source electrode, the drain electrode, and the substrate by an ink jet method. An applied amount of the liquid composition was determined...

example 2

[0213]A semiconductor device was manufactured by the same method as that in Example 1 except that the configuration of the liquid composition and the second solvent was changed as shown in Table 1.

example 3

[0214]A semiconductor device was manufactured by the same method as that in Example 1 except that the second solvent applying step was performed by exposing a base material having the liquid composition applied thereto into an atmosphere including the second solvent in a vaporized state. In the second solvent applying step, a temperature of the atmosphere was adjusted to 25° C., and a content of the second solvent in the atmosphere was adjusted to 22 g / m3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com