H218O production method and apparatus for rectifying 18O isotope enriched water

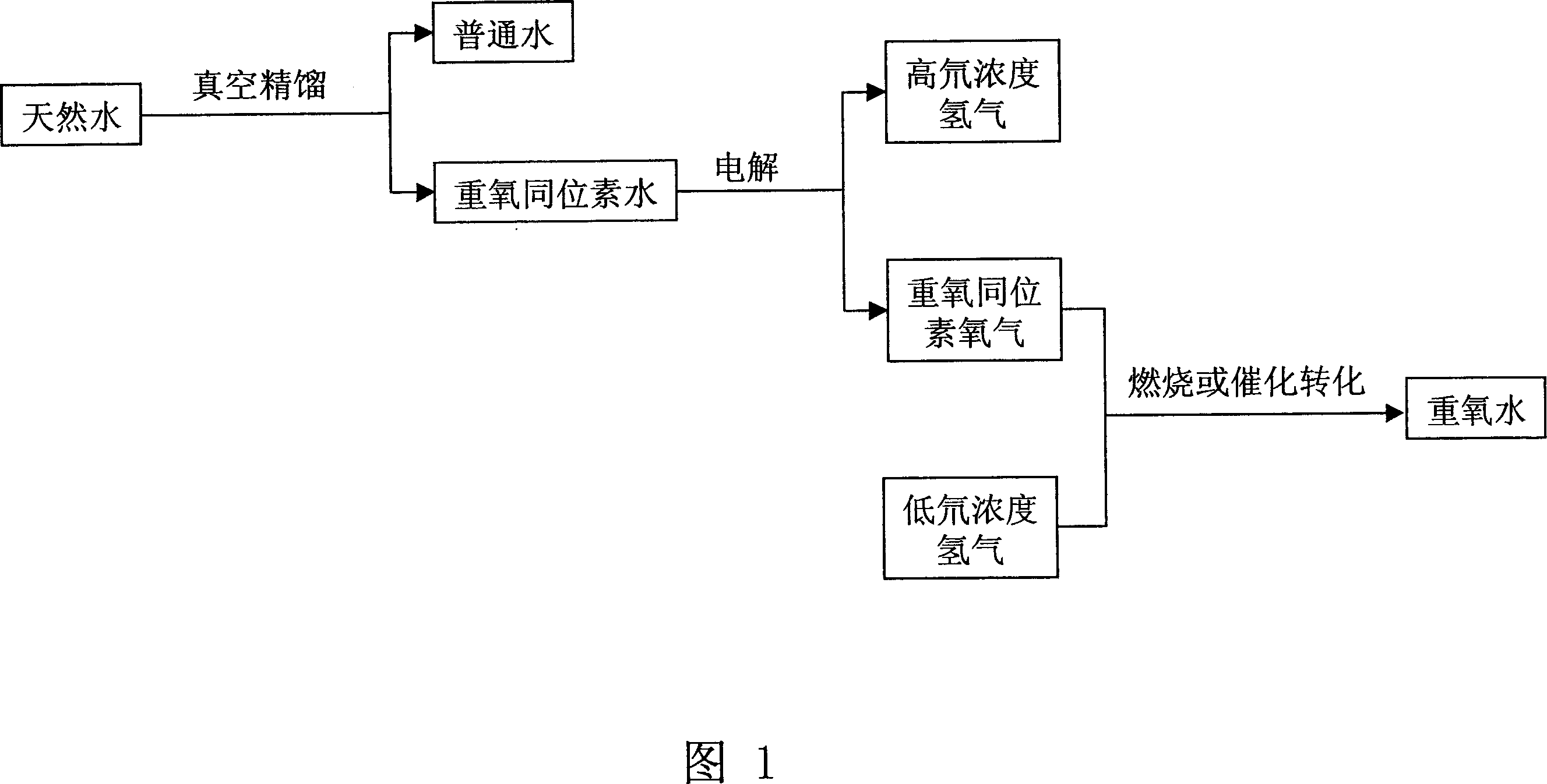

A technology of isotope and heavy oxygen water, which is applied in the field of water rectification device for enriching heavy oxygen isotope to produce heavy oxygen water and enriching heavy oxygen isotope water, to achieve the effect of convenient source, convenient operation and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

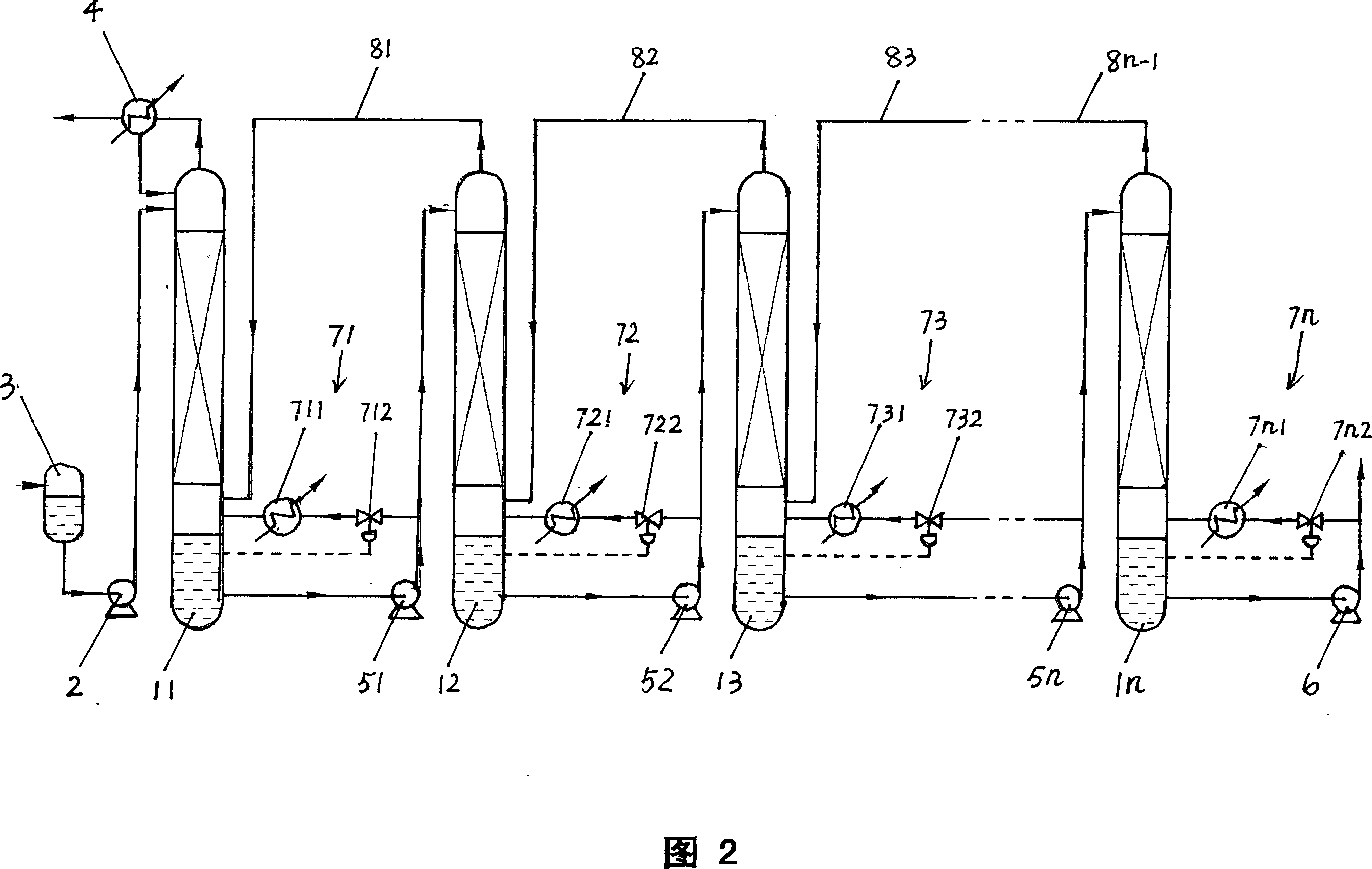

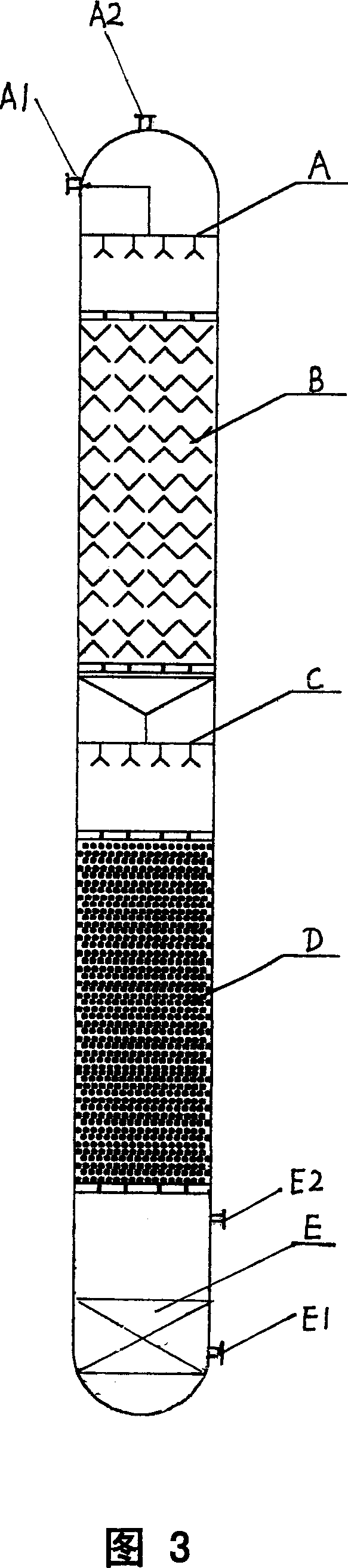

[0032] Raw water content 18 O0.2% atomic, 17 O0.04% atomic, 16 O99.76% atomic. The water rectification device is composed of three rectification towers connected in series. Among them, the diameter of the first rectification tower is 50 mm, and the height of the packing is 5 m; the diameter of the second rectification tower is 20 mm, and the height of the packing is 5 m; Vacuum is established for the three rectification towers respectively, and the feed pump sends the raw material water into the first rectification tower at 5Kg / h. The operating process conditions of each tower are as shown in table 1 (pressure shown in the table is absolute pressure):

[0033] Distillation column serial number

[0034] Operated by the process conditions shown in table 1, the third rectifying tower can be taken out containing 18 O15.0% atomic heavy oxygen water 0.5g / h, its deuterium content is 85.0% atomic. After electrolysis and hydrogenation combustion, a low-deuterium-contain...

Embodiment 2

[0036] Raw water content 18 O0.2% atomic, 17 O0.04% atomic, 16 O99.76% atomic. The water rectification device is composed of six rectification towers connected in series. Among them, the diameter of the first rectification tower is 100mm, the height of the packing is 5m, the diameter of the second rectification tower is 80mm, the height of the packing is 5m, the diameter of the third rectification tower is 50mm, the height of the packing is 5m, the diameter of the fourth rectification tower is 30mm, The height of the packing is 5m, the diameter of the fifth rectification tower is 20mm, the height of the packing is 5m, the diameter of the sixth rectification tower is 15mm, and the height of the packing is 5m. Vacuum is established for the six rectification towers respectively, and the feed pump sends the raw material water into the first rectification tower at 12Kg / h. The operating conditions of each tower are as shown in table 2 (pressure shown in the table is absolute pre...

Embodiment 3

[0040] Raw water content 18 O0.2% atomic, 17 O0.04% atomic, 16 O99.76% atomic. The water rectification device is composed of nine rectification towers connected in series / parallel. Among them, the first rectification tower to the fourth rectification tower form a series group, the fifth rectification tower and the sixth rectification tower form a series group, the seventh rectification tower to the ninth rectification tower form a series group, and the latter two are connected in series The groups are all connected after the fourth rectification tower to form a series / parallel water rectification device. The tower diameter and packing height of the first rectifying tower to the sixth rectifying tower are the same as embodiment 2, the tower diameter of the seventh rectifying tower is 20mm, and the packing height is 5m, the eighth rectifying tower tower diameter is 20mm, and the packing height is 5m, and the packing height is 5m. The diameter of the nine rectification towers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com