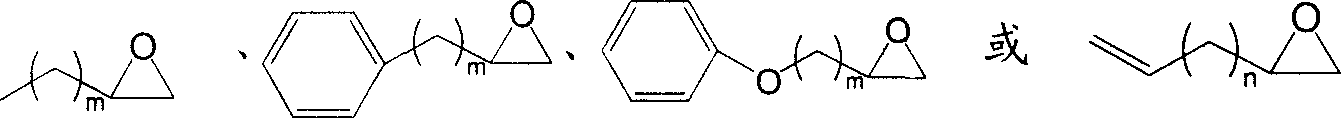

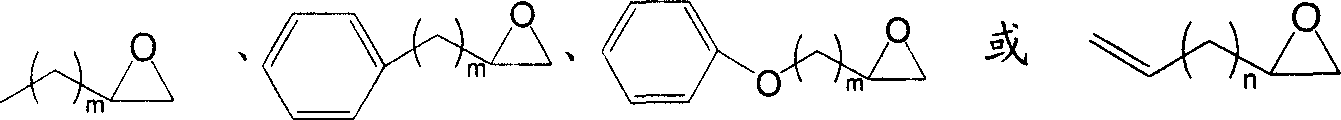

Addition reaction method for preparing cyclic carbonate from epoxide and carbon dioxide

A technology of epoxy compounds and cyclic carbonates, applied in organic chemistry and other directions, can solve the problem of less research on gold catalysts, and achieve the effects of easy separation, easy purification, and simple catalyst system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

[0019] Weigh 60 grams of resin with product code number 201×7, add 30 grams of sodium hydroxide, stir at room temperature for 6 hours, filter, dry at 80°C in air for 3 hours, add 60ml of 0.09% aqueous chloroauric acid solution in mass percentage After stirring slowly for 10 hours, dry at 80° C. in air for 3 hours to obtain the required catalyst Au-Na / D201 × 7, the gold mass percentage of the catalyst is 0.05%, and the mass percentage of sodium is 0.05% (implementation example 1).

[0020] Na 2 CO 3 , KOH and K 2 CO 3 One of them replaces NaOH, and all the other are the same as in Example 1 to obtain catalyst Au-Na / 201×7-1, Au-K / 201×7 and Au-K / 201×7-1, and the gold content of the catalyst is respectively 0.04 %, 0.05% and 0.04%, the mass percentage of alkali in the catalyst is respectively 0.02%, 0.03%, 0.05% (embodiment 2-4).

[0021] Replace D201×7 with one of 201×7FC, 201×7SC, 201×7MB, 201×7DL, 201×4, D201, D201FC, D201SC, D201MB and D202, and the rest are the same as i...

Embodiment 15-19

[0023] Add 2 g of Au-Na / 201×7 catalyst into a 1-liter high-pressure reactor equipped with electromagnetic stirring, add 40 ml of propylene oxide, introduce 3 MPa of carbon dioxide, heat the reactor to 120 ° C, and stir for 20 hours. The reactor was cooled to room temperature and the chromatographic yield of propylene carbonate was 81%.

[0024] The catalyst was directly reused 4 times, and the yields of propylene carbonate were 75%, 78%, 76% and 76%, respectively.

Embodiment 20

[0026] Add 2 grams of Au-Na / 201×7 catalyst into a 1-liter high-pressure reactor equipped with electromagnetic stirring, add 40 ml of 1,2-epoxyhexene, introduce 4 MPa of carbon dioxide, and heat the reactor to 100 ° C. The reaction was stirred for 24 hours. The reactor was cooled to room temperature, and the chromatographic yield of 1,2-hexenyl carbonate was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com