Functional ceramic material and its prepn process

A technology for health care materials and functional ceramics, which is applied in the field of ceramic health care materials with bioactivation function and its preparation, can solve the problems of poor durability of treatment and health care effects, insufficient use of performance, and need to improve health care effects. Good effect, accurate chemical composition control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

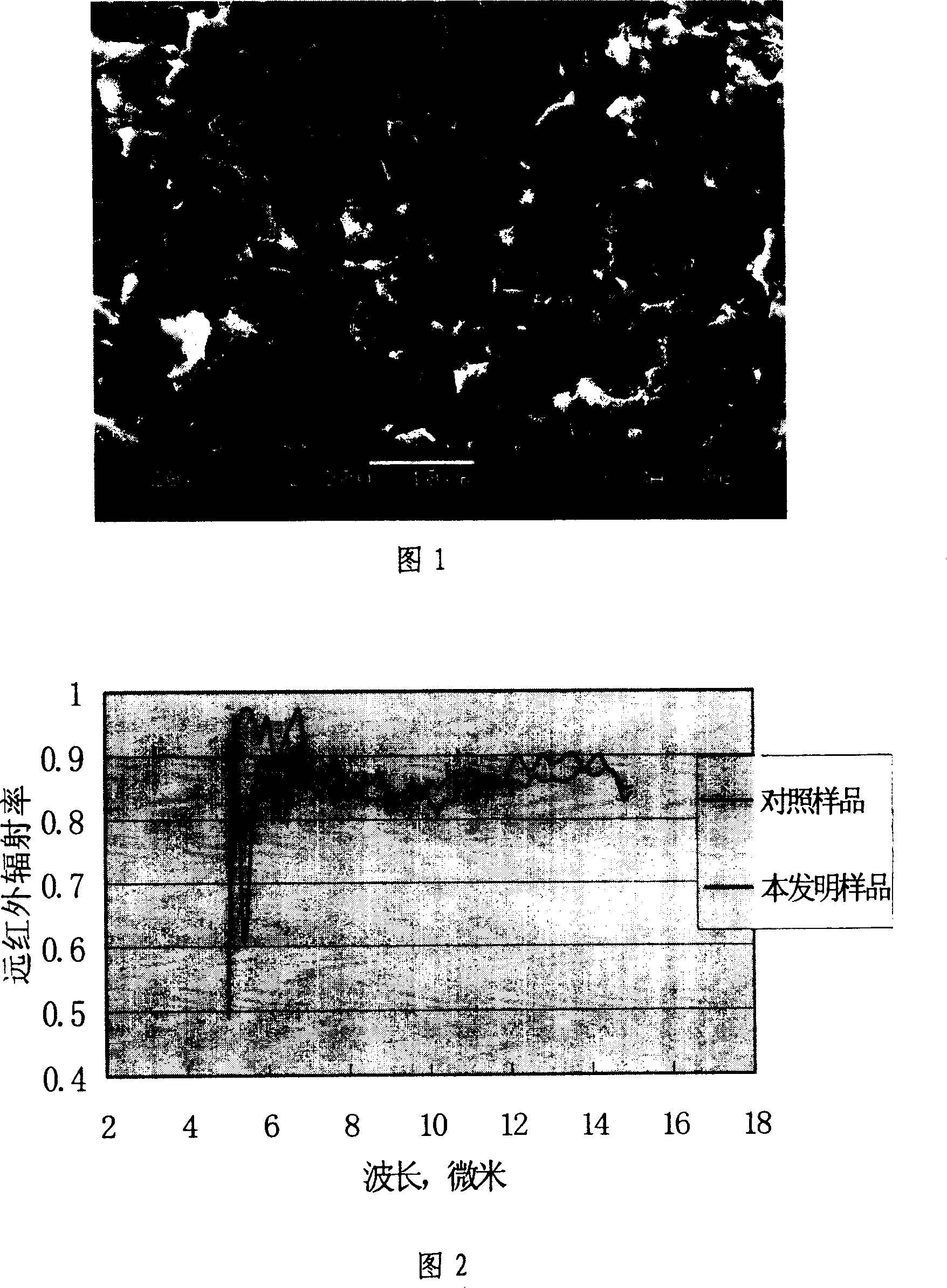

Image

Examples

Embodiment 1

[0042] A kind of functional ceramic health care material ceramic sheet (hereinafter referred to as ceramic sheet) is manufactured.

[0043] The weight percent raw material formula of ceramic sheet is:

[0044] Raw material formula 1: ferrite tourmaline 10%, strontium iron oxide 27%, calcined kaolin 10%, silicon oxide 10%, aluminum oxide 15%, calcium oxide 15%, neodymium nitrate 3%, cellulose 5%, polyacrylic acid 2% , castor oil 3%.

[0045] The preparation method of the ceramic sheet is as follows:

[0046] (1) Batching: according to the weight percentage raw material formula of ceramic sheet described in raw material formula 1, ceramic sheet raw material is prepared;

[0047] (2) Mixing: first ball mill the following raw materials to the following average particle size: tourmaline 8 μm, strontium iron oxide 2.5 μm, kaolin 4 μm, silicon oxide 2 μm, aluminum oxide 9 μm, calcium oxide 4 μm, and then mix with 3% neodymium nitrate , 5% cellulose, 2% polyacrylic acid and 3% cast...

Embodiment 2

[0059] Creates a ceramic sheet. The raw material formula of its weight percentage is:

[0060] Raw material formula 2: magnesium electric 15%, barium iron oxide 20%, calcined kaolin 10%, silicon oxide 15%, aluminum oxide 10%, calcium oxide 20%, europium nitrate 3%, cellulose 2%, polyacrylic acid 3%, Castor Oil 2%.

[0061] When mixing in this embodiment, add 22% water of the total weight of the raw material formula, and mix for 18 hours; mud refining adopts a vacuum mud refining machine, and the extrusion ratio is 1: 2; production capacity 8t / h; feeding screw shaft rotation The speed is 9r / min, and the rotation speed of the extrusion screw shaft is 7r / min; the moisture content of the blank is controlled to 1.5% before sintering, and it is dried at room temperature after molding; other procedures and processes are the same as in Example 1.

Embodiment 3

[0063] Creates a ceramic sheet. The present embodiment adopts described raw material formula 1.

[0064] When mixing materials in the process, add water with 15% of the total weight of the raw material formula, and mix the materials for 36 hours; vacuum mud refining machine is used for mud refining, and the extrusion ratio is 1:1; production capacity is 12t / h; the number of rotations of the feeding screw shaft 12r / min, the rotation speed of the extrusion screw shaft is 10r / min; it is fired in a roller kiln, the kiln is 25 meters long, it takes 3 and a half hours from entering the kiln to exiting the kiln, and the sintering temperature is up to 1100°C. Moisture content 2%; Other operation and technology are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com