Preparation method for pure-meat food and method for producing pure-meat food by the preparation

A manufacturing method and preparation technology, which is applied in the field of manufacturing pure meat food preparations and pure meat foods using the preparation, and can solve problems such as insufficient effect and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] According to the combination table in Table 1, weigh the auxiliary raw materials and water, mix them with a mixer, and prepare the basic salt juice.

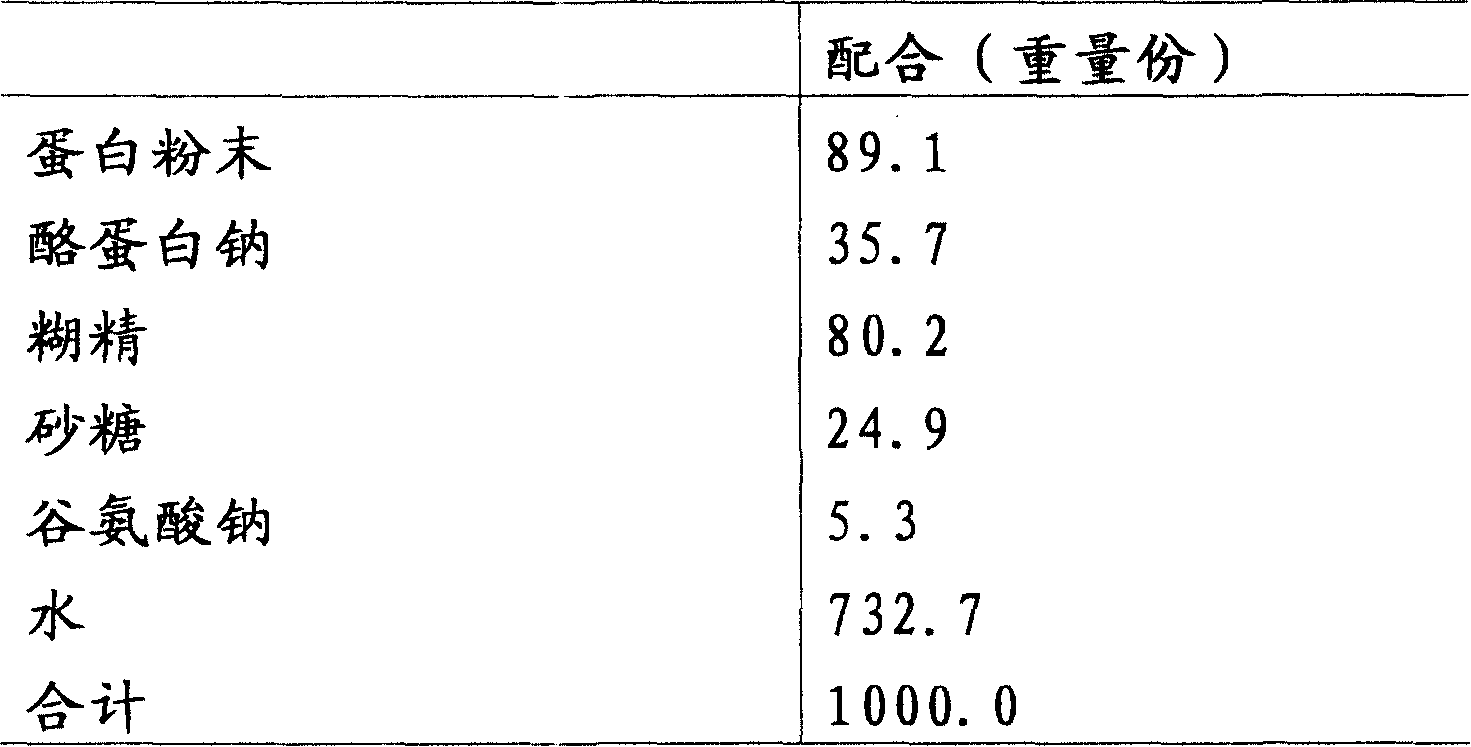

[0085] Table 1 The combination table of basic salt juice

[0086]

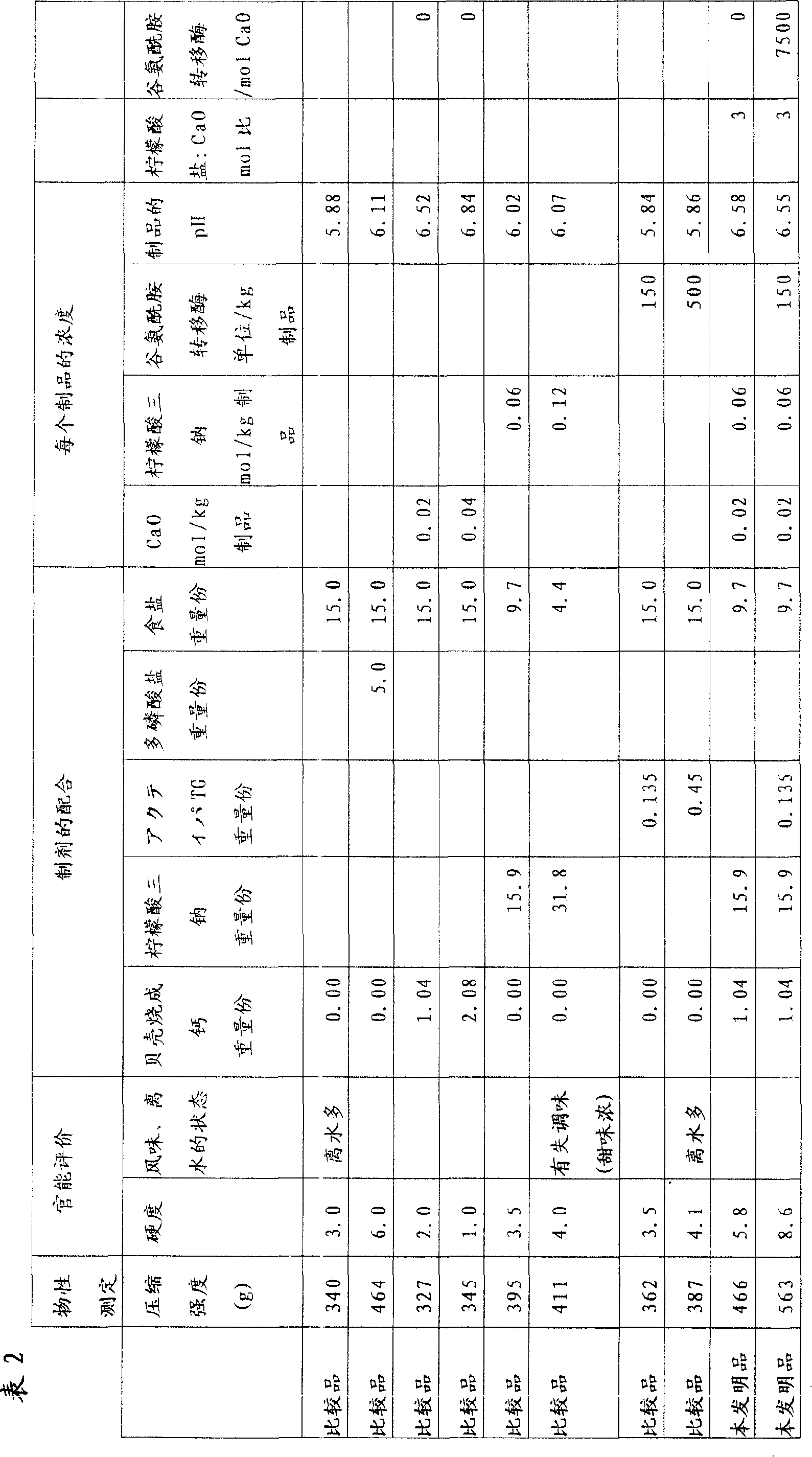

[0087] Then, according to the combination table of Table 2 (according to the amount recorded per 246 parts by weight of basic salt juice), shell fired calcium (made by Eヌシコポレシヨン, calcium oxide content 97%), citric acid Trisodium dihydrate (crystallization), Acteiba TG (specific activity of transglutaminase 1000 units / g), polyphosphate (a mixture of tetrasodium pyrophosphate and sodium tripolyphosphate in a weight ratio of 1:1), table salt, Mix the powder in advance, after preparing the preparation, put the total amount of the preparation into 246 parts by weight of the basic salt juice for each preparation, then add water to make the total amount 286 parts by weight, fully mix with a paddle mixer, and pass it into the colloid mill After neutralization...

Embodiment 2

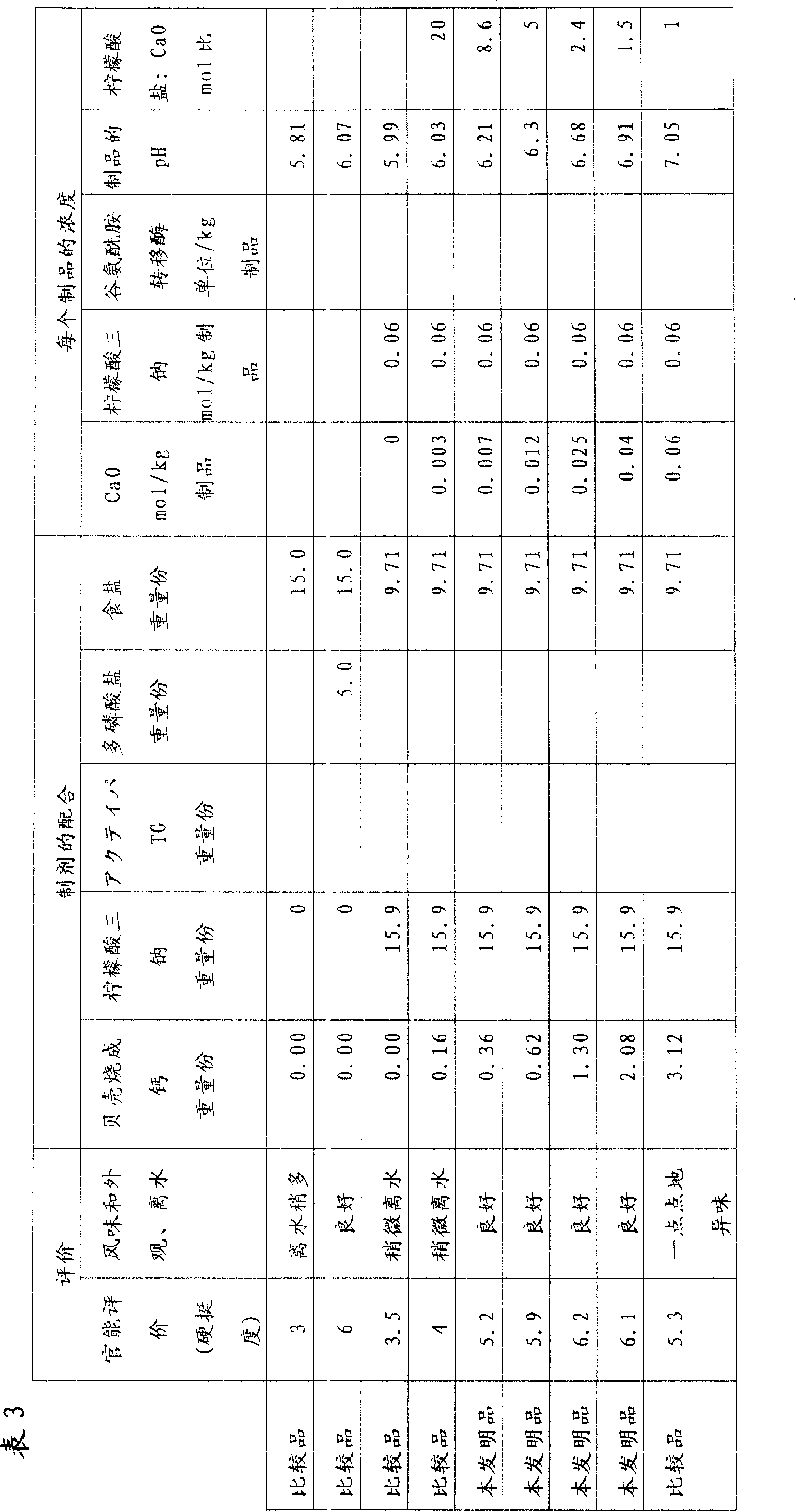

[0094] According to the composition table in Table 3, preparations and brine were prepared in the same manner as in Example 1, and tenderloin ham was prepared, and sensory evaluation and pH measurement were performed.

[0095]

[0096] As shown in Table 3, when more than 0.007 mol of calcined calcium is added per 1 kg of product, the pH of the product exceeds 6.2, and the hardness increases significantly. Corresponding to the increase in the amount of calcined calcium, the hardness also increases. However, the amount of calcined calcium added exceeds 0.040 mol per 1 kg of the product, and a slight odor occurs near the pH of the product exceeding 7.0.

Embodiment 3

[0098] According to the composition table in Table 4, preparations and brine were prepared in the same manner as in Example 1, and tenderloin ham was prepared, and sensory evaluation and pH measurement were performed.

[0099]

[0100] As shown in Table 4, when the molar ratio of the added amount of trisodium citrate to the calcium oxide derived from calcined calcium exceeds 1.5, the hardness increases significantly. In addition, the hardness also increased corresponding to the increase in the added amount of trisodium citrate. When the added amount of trisodium citrate exceeds 0.1 mole per 1 kg of product, the balance of taste will be destroyed, and the extremely sweet taste induced by the aftertaste will appear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com