Preparation method of catalyst for paraxylene produced by toluene selective disproporationation

A xylene catalyst and selectivity technology, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of less mesopores, affecting the diffusion rate of reaction products, affecting reaction activity and selectivity, etc. , to achieve the effect of increasing the diffusion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

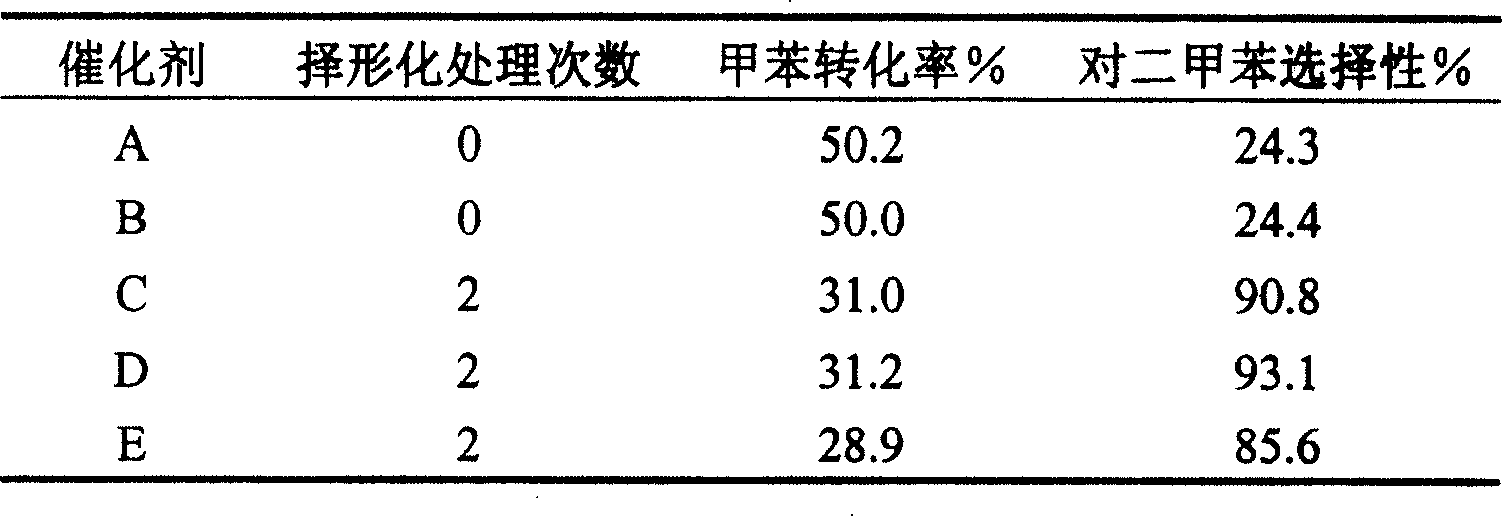

Embodiment 1

[0016] Get 40 grams of ammonium hydrogen type ZSM-5 former powder and add 25 grams of silica sol (by weight percentage, containing SiO 2 40%) and 5 milliliters of EO-PO copolymer nonionic surfactants, kneaded and extruded into strips, dried and baked at 500°C for 2 hours to obtain the shaped catalyst precursor A without shape-selective treatment, wherein EO is ring Ethylene oxide, PO is propylene oxide.

Embodiment 2

[0018] Get 40 grams of ammonium hydrogen type ZSM-5 former powder and add 25 grams of silica sol (by weight percentage, containing SiO 2 40%) and 3.0 grams of hay powder (below 200 orders), kneaded and extruded into strips, dried at 500 ° C for 2 hours to obtain the shaped catalyst precursor B without shape-selective treatment.

Embodiment 3

[0020] Get 50 grams of catalyst precursor A, add 48 milliliters of n-hexane and 2.5 grams of benzyl silicone oil (average molecular weight about 600) as the solution, and distill off n-hexane in an oil bath at 90°C. The residue after evaporating to dryness was heated up to 500° C. in a muffle furnace, kept for 3 hours, and then naturally cooled to obtain a catalyst subjected to a shape-selective treatment. Repeat the above-mentioned silicone oil modification treatment process to obtain a finished catalyst product C, the catalyst mesopore part ( ≥20A) pore volume 0.22 ml / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com