Method for preparing olefin by catalytic oxidation of petroleum hydrocarbon

A technology for catalytic oxidation and petroleum hydrocarbons, applied in the field of low-carbon olefins, can solve the problems of complex equipment and high energy consumption, and achieve the effects of reducing energy consumption, improving process efficiency, and easy realization of heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

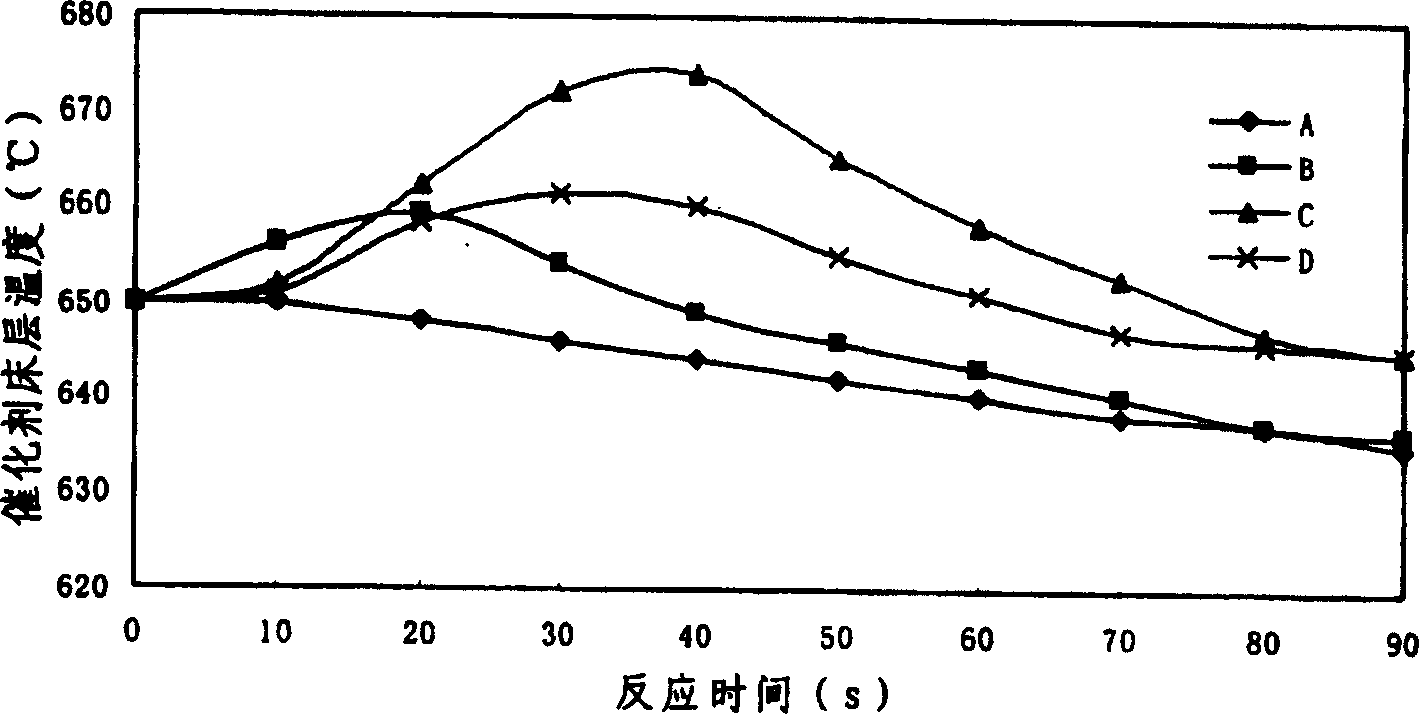

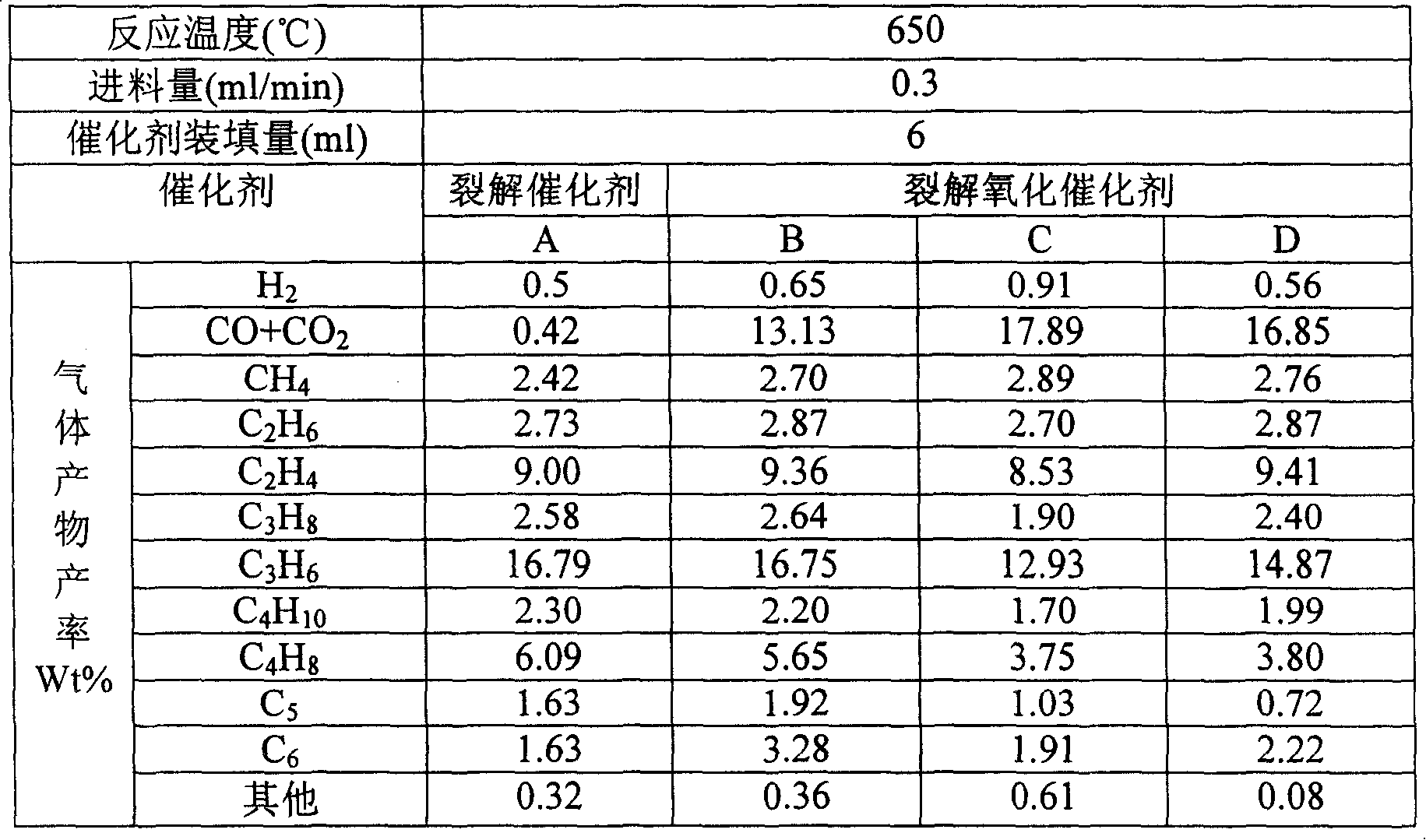

[0018] Fixed bed reactor, the reaction raw material is naphtha, the composition is shown in Table 1. The cracking catalyst is a solid acid catalyst A; the cracking catalyst and three different metal oxide catalysts are uniformly mixed at a volume ratio of 6.5:1 to obtain catalysts B, C and D. The properties of the catalysts are shown in Table 2. The reaction tube has an inner diameter of 6 mm and a tube length of 300 mm. The reaction tube has a jacket outside. When the reaction is carried out, the inside of the jacket is evacuated, and the external heating furnace is closed to stop heating. figure 1 ). The particle size of the catalyst is 40-60 mesh, and the loading amount of the catalyst is 6ml. The reaction carrier gas was pure nitrogen, and the carrier gas flow rate was 22.5ml / min. After 1.5 minutes of reaction, the product passed through the cold trap and collected the gas product by draining the gas. The reaction results are shown in Table 3. Under the action of catalys...

Embodiment 2

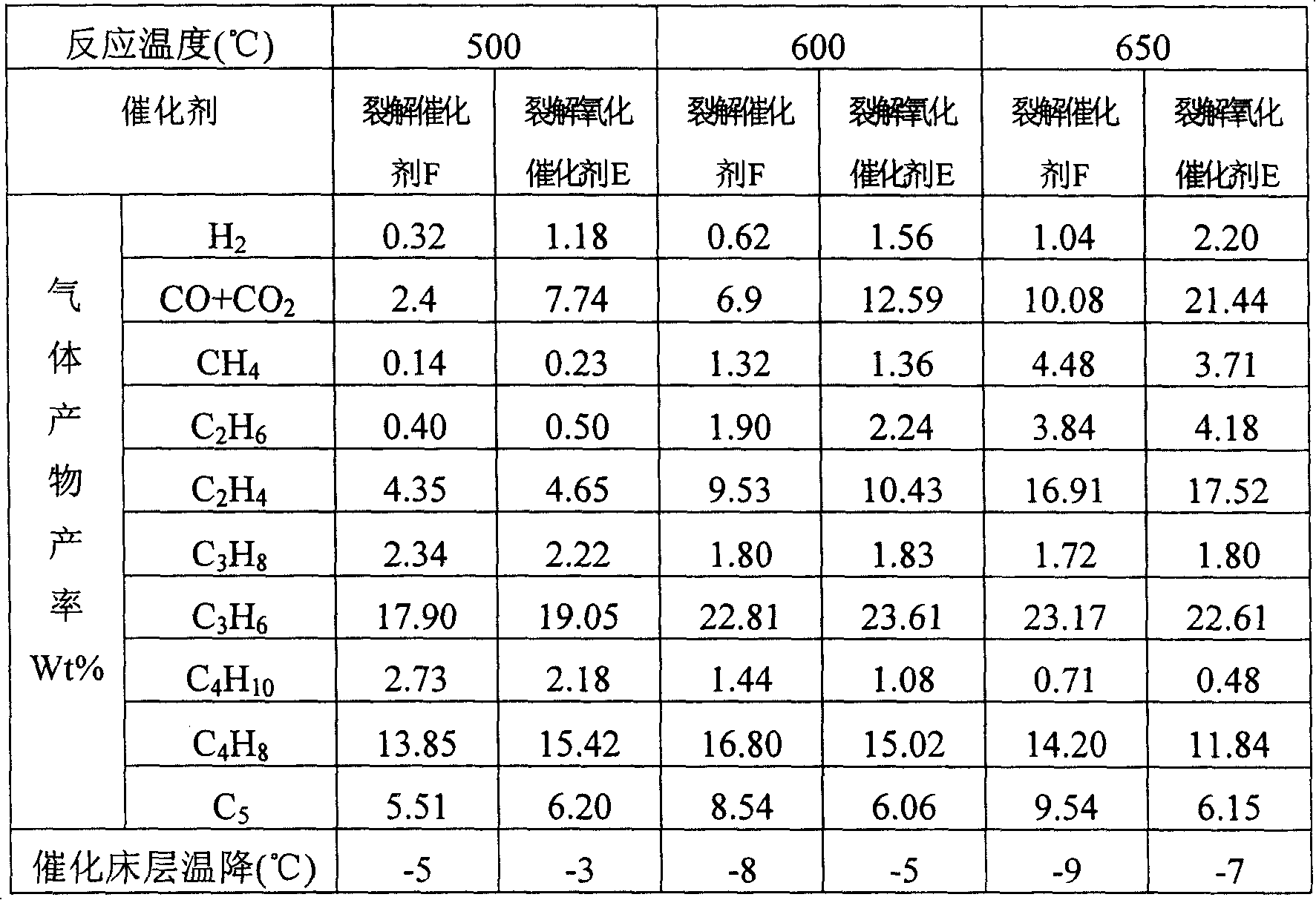

[0027] Fixed fluidized bed reactor, the reaction raw material is Daqing atmospheric residue, and the physical and chemical properties of Daqing residue are shown in Table 4. Composite catalyst E is a mixture of solid acid catalyst F (Chinese patent 03141148.7) and metal oxide catalyst G. The physical properties of the catalyst are shown in Table 5. The weight ratio of F and G is 10:1. Under the action of pure solid acid catalyst F and composite catalyst E respectively, the agent-oil ratio is 18:1, the water-oil ratio is 0.3:1, the reaction time is 60 seconds, the reaction temperature is 500°C, 600°C, 650°C, the reaction results See Table 6.

[0028] Table 4: Physicochemical Properties of Raw Materials

[0029] Density (kg / m 3 )

Kang's carbon residue (m%)

Hydrogen content (m%)

average relative molecular weight

0.9113

4.37

13.12

592

[0030] Table 5: Physical and chemical indicators of catalysts F and G

[0031] ...

Embodiment 3

[0036] The composite catalyst is regenerated after reacting in the reactor, the solid acid catalyst is regenerated by burning, and the metal oxide is regenerated by oxidation. The reaction results after catalyst regeneration are shown in Table 7. The catalyst used for the reaction is E, the reaction temperature is 650° C., and other reaction conditions are the same as in Example 2.

[0037] Table 7: Reaction results after regeneration of cracking oxidation catalyst E

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com