Synthetic method for crosslinking agent-pentaerythritol allyl ether for high molecular polymerization

A technology of pentaerythritol allyl ether and polymer polymerization, applied in ether preparation, organic chemistry and other directions, can solve the problems of poor selectivity, dark product color, low yield of polyol ether, etc., to improve the reaction selectivity and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

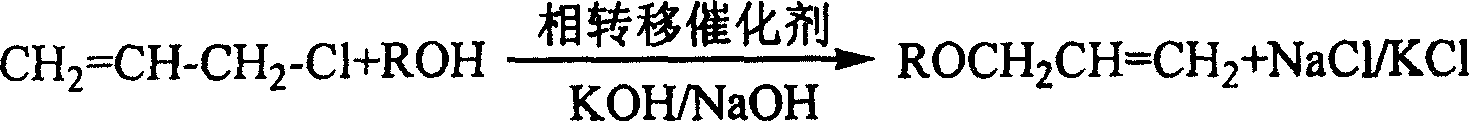

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Add 800g pentaerythritol, 700g sodium hydroxide, 1353g allyl chloride, 450gPEG800, 700g distilled water in 5L, 316L stainless steel reactor, pressurize to 0.2MPa with nitrogen, check airtightness, heating starts Stir, stir and react at a temperature of 60-120°C for 8-10 hours, take samples and analyze the materials in the kettle, after the etherification reaction is completed, discharge the materials while they are hot, separate the sodium chloride from the reaction mixture by centrifugation, and pour the filtrate into the liquid separation tank, and add an equal volume of tap water, and add metered 20% hydrochloric acid aqueous solution to neutralize, the pH value is about 7, then static layering, the lower water layer is separated, the upper oil phase is returned to the reactor, and the vacuum is 20mmHg , dehydration under reduced pressure at a temperature of 100°C to 120°C, removal of trace by-products of propylene alcohol and low molecular weight substa...

Embodiment 2

[0023] In reactor, add 800g pentaerythritol, 982g potassium hydroxide, 1353g allyl chloride, 450gPEG800, 982g distilled water, the condition and operation of synthetic pentaerythritol allyl ether are the same as embodiment 1, filter to obtain refining pentaerythritol allyl ether mixture 1100g, The yield is 81.3% (based on the amount of allyl chloride charged), and its mass composition is 10% pentaerythritol allyl disubstituted; trisubstituted 72%; tetrasubstituted 18% through gas chromatographic analysis.

Embodiment 3

[0025] Add 800g pentaerythritol, 700g sodium hydroxide, 1353g allyl chloride, 200g tetrabutylammonium bromide, 700g distilled water in the reaction kettle, the condition and operation of synthetic pentaerythritol allyl ether are the same as embodiment 1, filter to obtain refined pentaerythritol propane Allyl ether mixture 1070g, yield is 79.1% (in terms of allyl chloride charging amount), through gas chromatography analysis and identification, its mass composition is pentaerythritol allyl ether disubstituted 7%; Three substituted 70%; Four substituted twenty three%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com