Technological method for treating carbolic acid waste water by electrochemical oxidation

An oxidation treatment and electrochemical technology, applied in electrochemical water/sewage treatment, electrode, electrolysis process, etc., can solve the problems of poor electrode stability and low treatment efficiency, and achieve fast reaction rate, high current efficiency and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The titanium substrate was first polished with sandpaper, and then the titanium plate was boiled for a certain period of time with 5% NaOH solution, rinsed with distilled water after taking it out; and then the titanium plate was etched with 10% oxalic acid solution.

[0017] The tin-antimony metal oxide layer is prepared by a thermal decomposition method using a polymeric precursor. At 60°C, add 0.2 mol of citric acid to 1.0 mol of ethylene glycol, and after the citric acid is completely dissolved, add 0.065 mol of SnCl 4 ·5H 2 O and 7.1×10 -3 mol of SbCl 3 , fully stirred and heated to 90° C., and kept at a constant temperature for 30 minutes to prepare a tin-antimony-containing polymer precursor. The precursor was coated on the titanium substrate, kept in an oven at 130°C for 10 minutes, then transferred to a muffle furnace at 500°C for 10 minutes, and repeated 10 times, with the last firing for 30 minutes.

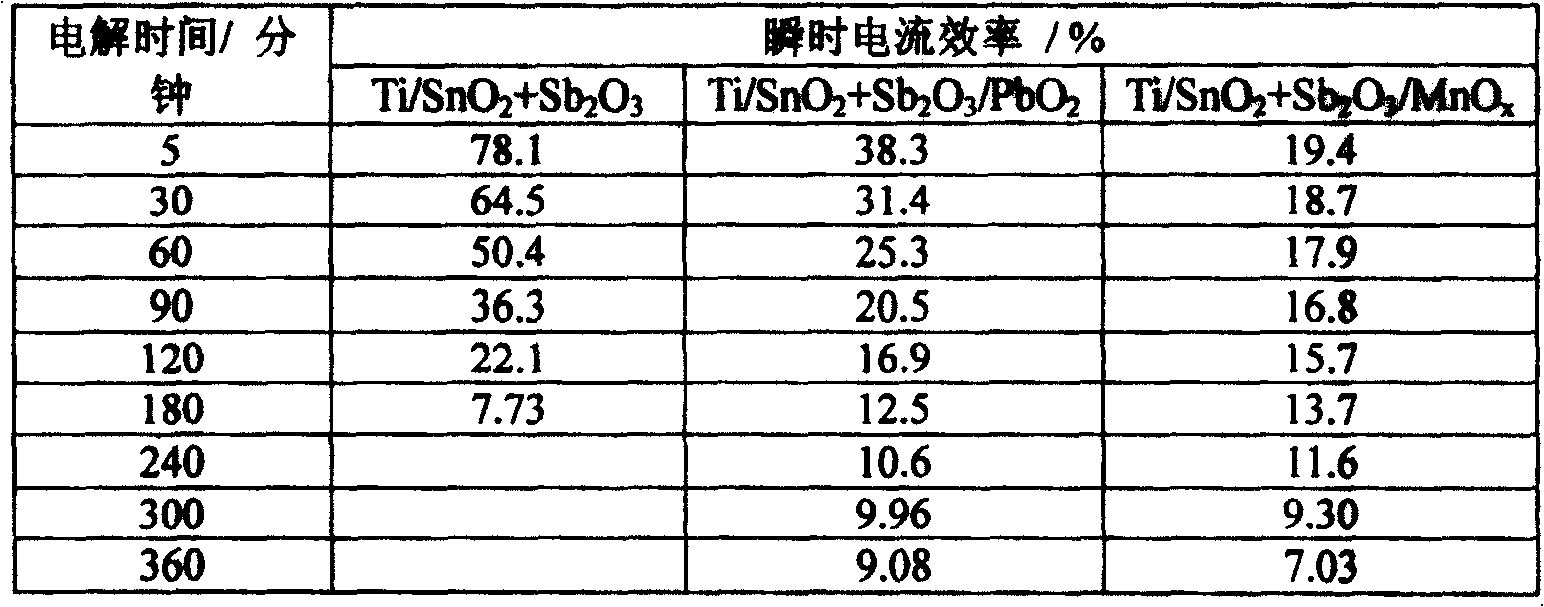

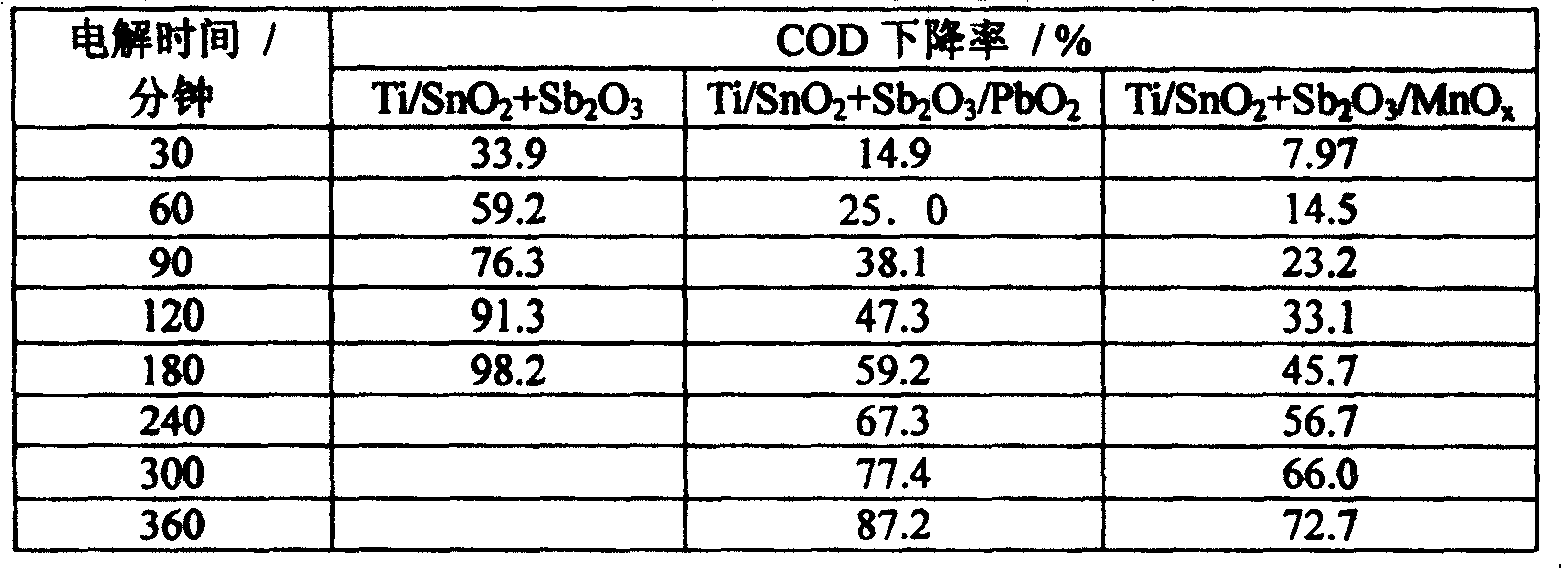

[0018] The concentration of phenol in wastewater is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com