Controlled cooling heat treating process and its device for bainite ductile iron

A technology of bainitic nodular graphite and controlled cooling, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the large-scale promotion and application restrictions of nodular cast iron wear parts, high production cost of bainitic nodular cast iron, easy to form Problems such as carbides or oxides, to achieve the effect of low cost, simple structure, and improved hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

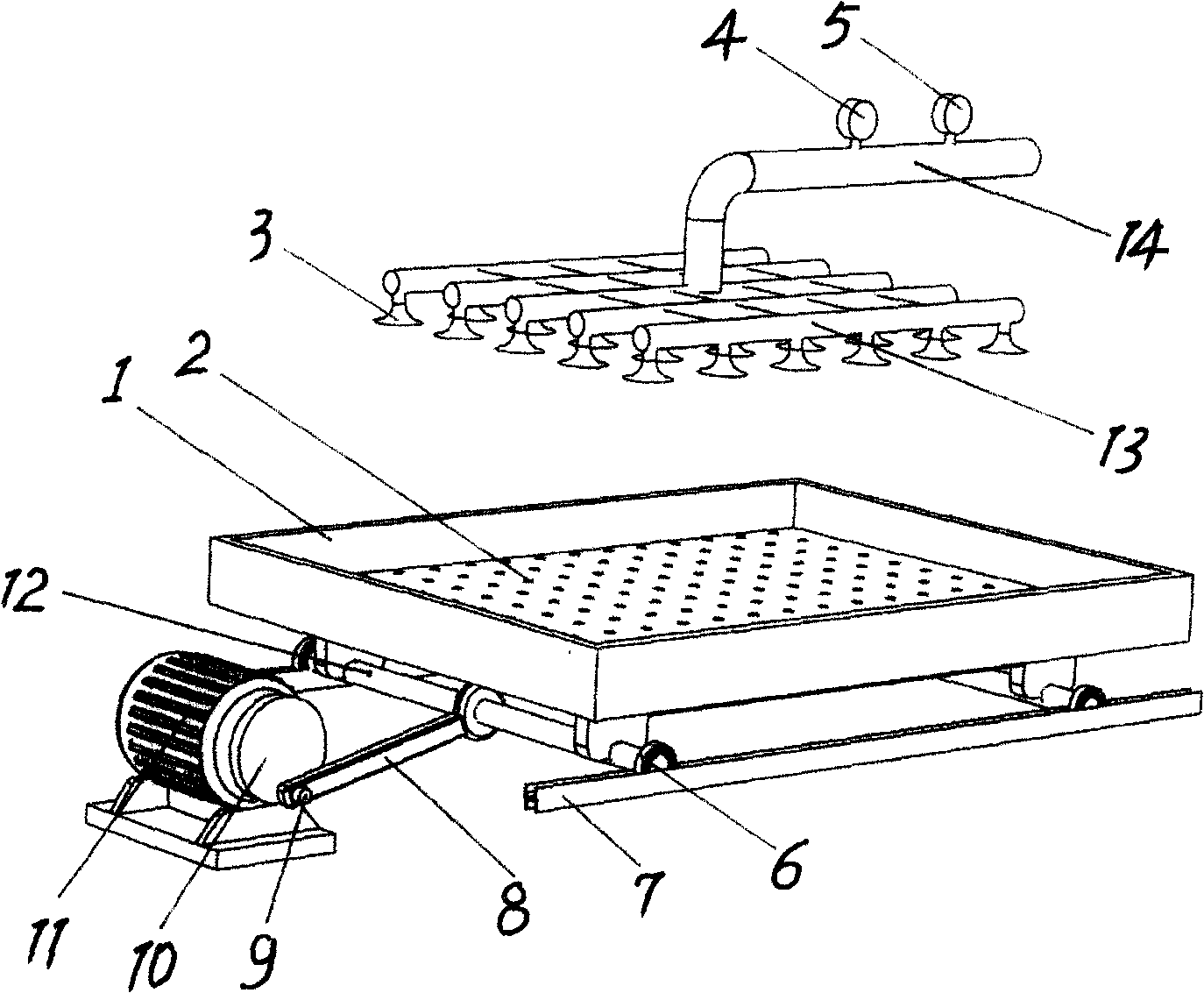

[0016] Attached below figure 1 The atomizing spray device of the present invention is further described.

[0017] figure 1 Among them, a drainage hole 2 is provided on the bottom plate of the workpiece table 1, two symmetrical wheel axles 12 are installed under the workbench 1, and rollers 6 are installed at both ends of each wheel axle 12, and the rollers 6 are placed on the guide rail 7, so that on the guide rail 7 Rolling, wherein the wheel shaft 12 is connected to one end of the connecting rod 8, the other end of the connecting rod 8 is fixed on the eccentric shaft 9, and the eccentric shaft 9 is fixed on the runner 10 connected to the output shaft of the motor 11, so that the eccentric shaft on the runner 10 The shaft 9 and the connecting rod 8 change the circular motion into a linear motion, so that the workbench 1 moves back and forth under the drive of the motor 11; above the workbench 1, there is a tube group 13, and each tube is equipped with multiple nozzles 3, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com