Method for producing nickel belt

A manufacturing method and technology of nickel strips, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal rolling, etc., can solve the problems of reducing the purity of nickel strips, increasing the internal resistance of nickel strips, and low production efficiency, so as to reduce labor costs , shortened production cycle, and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

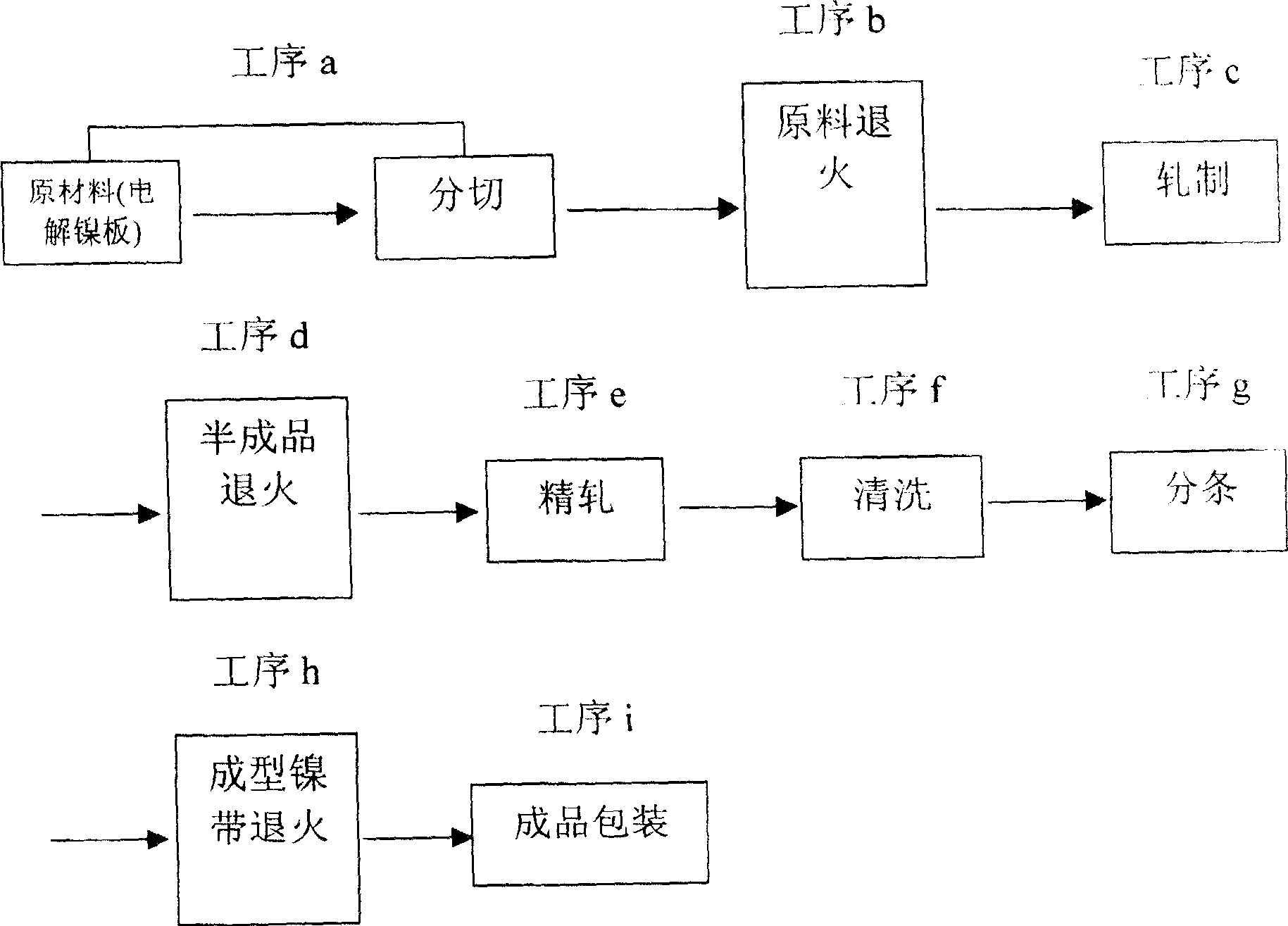

[0043] Such as figure 2 As shown, this embodiment includes the following steps:

[0044] a. Slitting the high-purity electrolytic nickel plate;

[0045] b. Heat the slit electrolytic nickel plate to 300°C, keep it warm for 10 hours, and perform raw material annealing treatment to fully analyze harmful substances such as hydrogen and sulfur in the electrolytic nickel plate, improve material properties, reduce brittleness, and increase toughness; resistance can be used Furnace (including well-type or horizontal inert gas atmosphere protection furnace, inert gas can use argon, nitrogen, etc., the following semi-finished products, finished annealing well-type inert gas atmosphere protection furnace is the same), or diesel combustion box-type heating furnace for annealing treatment ;

[0046] c. Rolling the pretreated electrolytic nickel plate; rolling includes repeated rolling, so that the thickness of the nickel plate is gradually rolled to the semi-finished product thickness ...

Embodiment 2

[0060] Such as figure 2 As shown, the steps of this embodiment are the same as that of Embodiment 1, the only difference is that the heating temperature is 410° C. and the temperature is kept constant for 7 hours.

Embodiment 3

[0062] Such as figure 2 As shown, the steps of this embodiment are the same as those of Embodiment 1, except that the heating temperature is 450° C. and the temperature is kept constant for 5 hours.

[0063] In the above three embodiments, the tolerance of the annealing heating temperature of the finished product is controlled within ±5° C., which can obtain a better processing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com