A layered cement base piezoelectric intelligent composite material and a preparation method thereof

A technology of cement-based materials and composite materials, which can be applied to measurement devices, instruments, building components, etc., can solve the problems of affecting the sensing and driving functions of piezoelectric ceramics, high deformation coordination and cost, and poor anti-interference ability, and achieve good Interfacial adhesion and deformation coordination, improved sensitivity and long-term stability, strong and stable piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

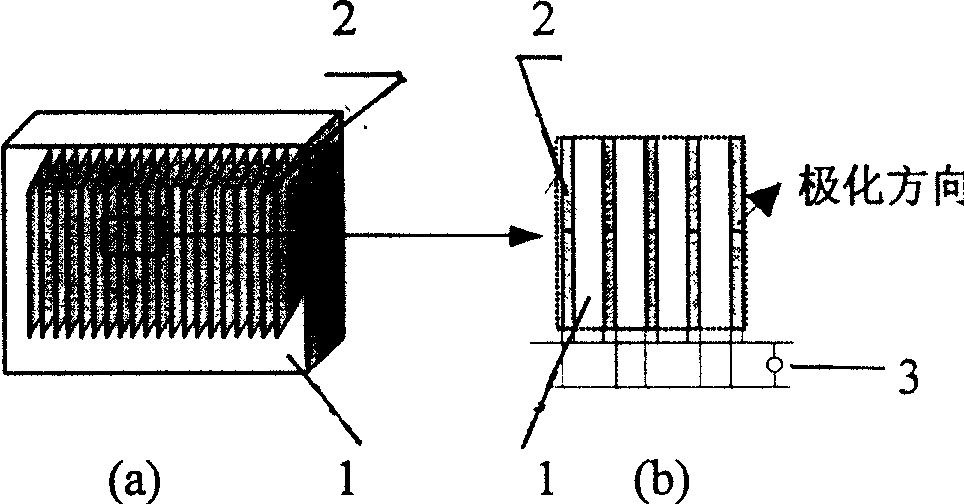

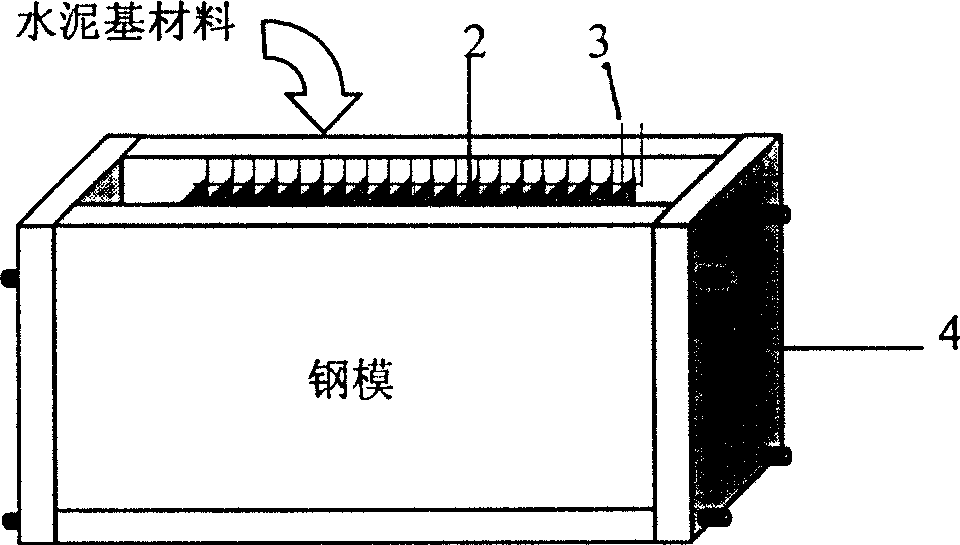

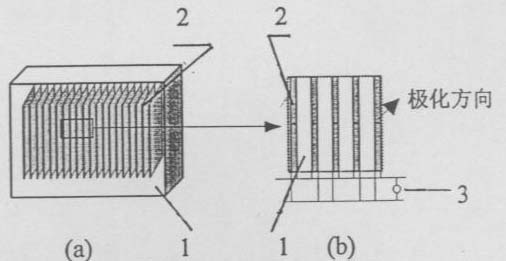

Embodiment 1

[0022] Using PZT piezoelectric ceramic sheet, piezoelectric constant d 33 650×10 -12 Above C / N, electromechanical coupling coefficient K 33 70%, mechanical quality factor Q m It is 80, the Curie temperature is 260 degrees, the relative permittivity is 2300, the size is 20mm×30mm×0.2mm, and the electrode size is 17mm×27mm. The internal size of the steel mold used is 18mm×35mm×50mm, the groove spacing in the steel mold is 0.8mm, the groove width is 0.22mm, the groove depth is 1.1mm, and the number of grooves is 40. Common enameled wires are used to connect piezoelectric ceramic sheets and electrodes inside the composite material. The raw materials of cement-based materials are 52.5 Portland cement, a commercial superplasticizer with a water-reducing rate of 20%, quartz sand with a maximum particle size of 100 μm, and SiO 2 The content is 97% silica fume. The mixing ratio of cement-based materials is: cement: water: quartz sand: silica fume: superplasticizer = 90:28:100:10:1...

Embodiment 2

[0024] Using PMgN piezoelectric ceramic sheet, piezoelectric constant d 33 500×10 -12 Above C / N, the electromechanical coupling coefficient is 71%, and the mechanical quality factor is Q m It is 70, the Curie temperature is 280 degrees, the relative permittivity is 3800, the size is 20mm×30mm×0.2mm, and the electrode size is 17mm×27mm. The internal size of the steel mold used is 18mm×35mm×50mm, the groove spacing in the steel mold is 0.8mm, the groove width is 0.22mm, the groove depth is 1.1mm, and the number of grooves is 40. Common enameled wires are used to connect piezoelectric ceramic sheets and electrodes inside the composite material. The raw materials of cement-based materials are 52.5 Portland cement, a commercial superplasticizer with a water-reducing rate of 20%, quartz sand with a maximum particle size of 100 μm, and SiO 2 The content is 97% silica fume. The mixing ratio of cement-based materials is: cement: water: quartz sand: silica fume: superplasticizer = 9...

Embodiment 3

[0026] Using PZT piezoelectric ceramic sheet, piezoelectric constant d 33 650×10 -12 Above C / N, electromechanical coupling coefficient K 33 70%, mechanical quality factor Q m It is 80, the Curie temperature is 260 degrees, the relative permittivity is 2300, the size is 20mm×30mm×0.2mm, and the electrode size is 17mm×27mm. The internal size of the steel mold used is 18mm×35mm×50mm, the groove spacing in the steel mold is 0.2mm, the groove width is 0.22mm, the groove depth is 1.1mm, and the number of grooves is 100. Common enameled wires are used to connect piezoelectric ceramic sheets and electrodes inside the composite material. The raw materials of cement-based materials are 52.5 Portland cement, a commercial superplasticizer with a water-reducing rate of 20%, quartz sand with a maximum particle size of 100 μm, and SiO 2The content is 97% silica fume. The mixing ratio of cement-based materials is: cement: water: quartz sand: silica fume: superplasticizer = 90:28:100:10:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com