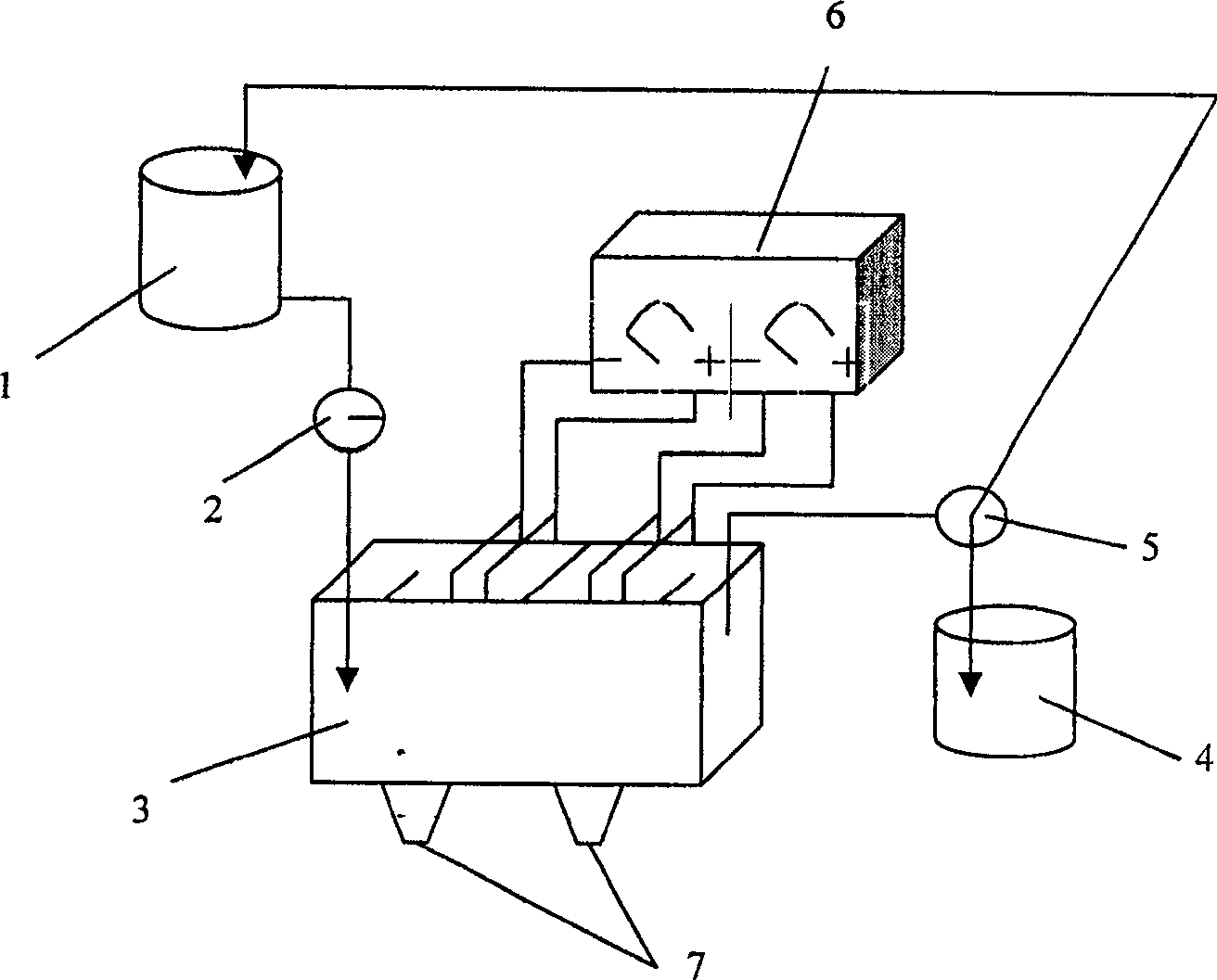

Ultrasonic-electrical catalyzing treatment azo dyes waste water processing device and reaction conditions

A technology for catalyzing azo and dye wastewater, applied in the direction of electrochemical water/sewage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc., to improve the reaction speed, utilization rate, and reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

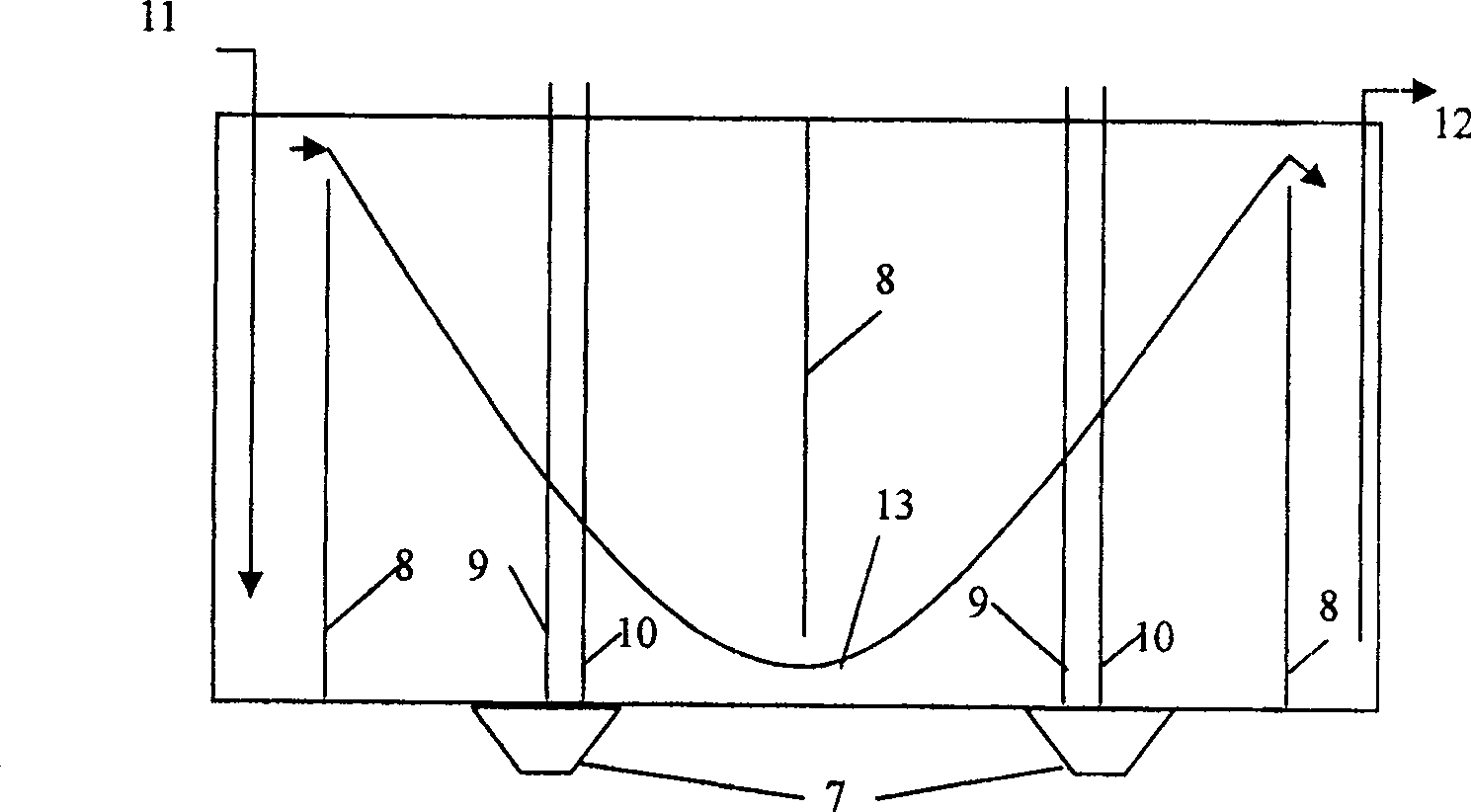

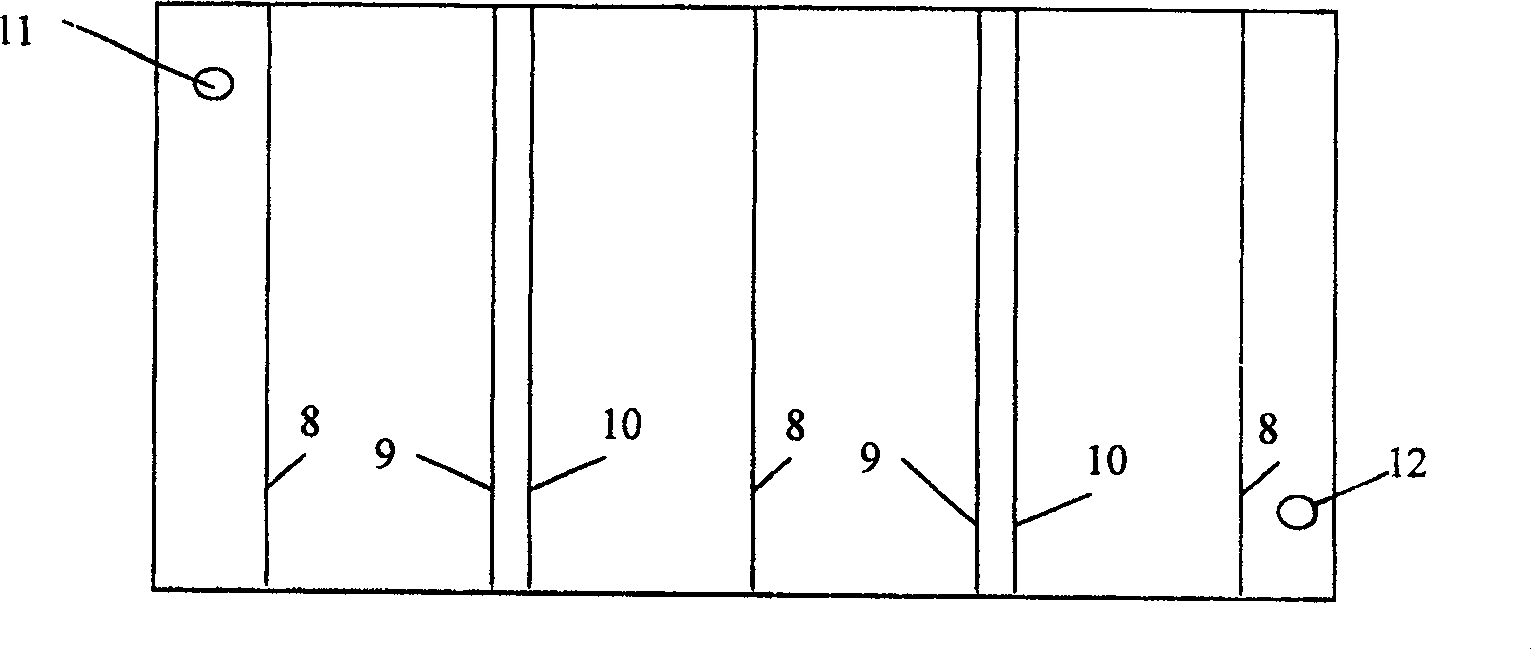

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: prepare 300mg / L methyl orange simulated waste water 1000mL, test in the device of the present invention, concrete reaction conditions and treatment effect are as follows:

[0026] Reaction conditions:

[0027] Ultrasonic input power: 0.5W / cm 2 ;

[0028] Ultrasonic frequency: 59kHz

[0029] Operating voltage of thyristor ballast: 8V;

[0030] Concentration of supporting electrolyte NacL: 0.03mol / L;

[0031] Corresponding current density: 18mA / cm 2 ;

[0032] Flow rate: 50mL / min.

[0033] Plate spacing: 5mm

[0034] Cycle processing time: 120min

[0035]

Embodiment 2

[0036] Embodiment 2: prepare 100mg / L methylene blue simulated waste water 1000mL, test in the device of the present invention, concrete reaction condition and treatment effect list are as follows:

[0037] Reaction conditions:

[0038] Ultrasonic input power: 0.5W / cm 2 ;

[0039] Ultrasonic frequency: 59kHz

[0040] Operating voltage of thyristor ballast: 8V;

[0041] Concentration of supporting electrolyte NaCl: 0.03mol / L;

[0042] Corresponding current density: 18mA / cm 2 ;

[0043] Flow rate: 25mL / min.

[0044] Plate spacing: 5mm

[0045] Cycle processing time: 80min

[0046]

Embodiment 3

[0047] Example 3: Prepare 5000mL of 300mg / L methyl orange simulated waste water, test in the device of the present invention, do not start the circulation device, turn on the ultrasonic wave 60 minutes before the reaction, turn off the ultrasonic wave after 60 minutes for separate electrochemical degradation, and then pass through 30 minutes after the excessive Sampling for testing. The specific test reaction conditions and treatment effect data are listed as follows:

[0048] Reaction conditions:

[0049] Ultrasonic input power: 0.5W / cm 2 (60 minutes ago);

[0050] Ultrasonic frequency: 59kHz (before 60min);

[0051] Operating voltage of thyristor ballast: 8V;

[0052] Concentration of supporting electrolyte NaCl: 0.03mol / L;

[0053] Corresponding current density: 18mA / cm 2 ;

[0054] Flow rate: 20mL / min.

[0055] Plate spacing: 5mm

[0056] Processing time: 250min

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com