Thermostable composition of low dielectric loss and its preparing process

A composition and low dielectric technology, applied in the field of dielectric composite material preparation, can solve the problems of unfavorable research and development of high-stability products, high dielectric loss of composite materials, small particle size of inorganic fillers, etc. The effect of high constant and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to A1 listed in Table 1, bisphenol A type dicyanate (BADCy) and BaTiO 3 (400 mesh) mixed according to the proportion, the mixture was heated and melted in an oil bath at 100°C, and then heated to 150°C for pre-curing for 4 hours, BaTiO 3 Without obvious sedimentation, an organic / inorganic binary composition with adjustable dielectric constant and low dielectric loss is obtained.

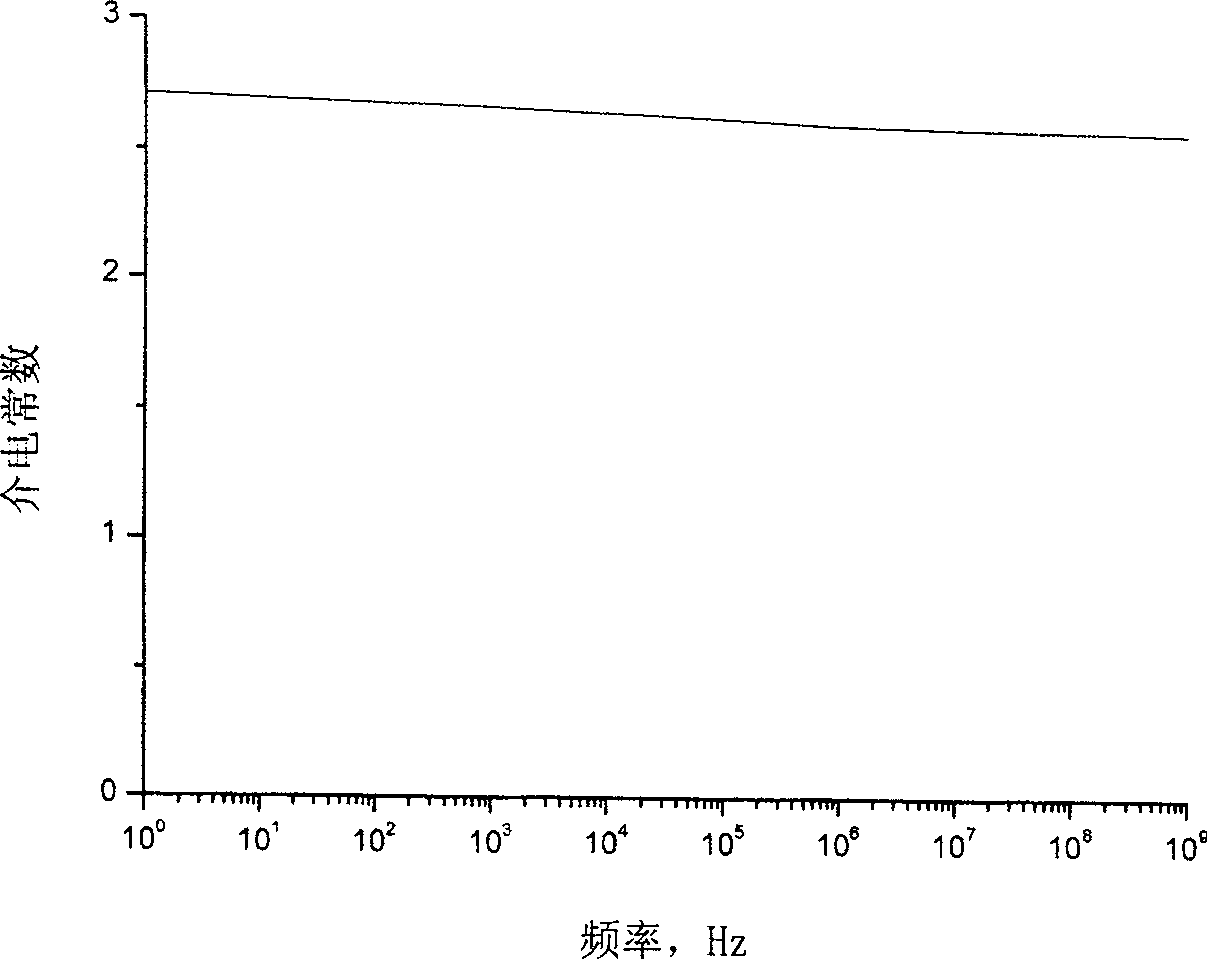

[0024] Inject the composition into a preheated (150°C) mold, degas it in a vacuum oven at 100-105°C for 30 minutes, and cure it according to the process of 160°C / 2h+180°C / 2h+200°C / 2h , according to the process of 230 ℃ / 5h for post-treatment, that is, get BADCy / BaTiO 3 composite material. Test the dielectric constant in the range of 1Hz ~ 10GHz, its value is as attached figure 1 shown. It can be seen that the dielectric constant of the material is stable over the entire test frequency range.

Embodiment 2 7

[0026] According to the formulas A1~A7 listed in Table 1, bisphenol A type dicyanate (BADCy) and BaTiO 3 (400 mesh) mixed according to the proportion, the mixture was heated and melted in an oil bath at 100°C, and then heated to 150°C to pre-cure for a certain period of time until BaTiO 3 Without obvious sedimentation (as shown in Table 1), an organic / inorganic binary composition with adjustable dielectric constant and low dielectric loss is obtained.

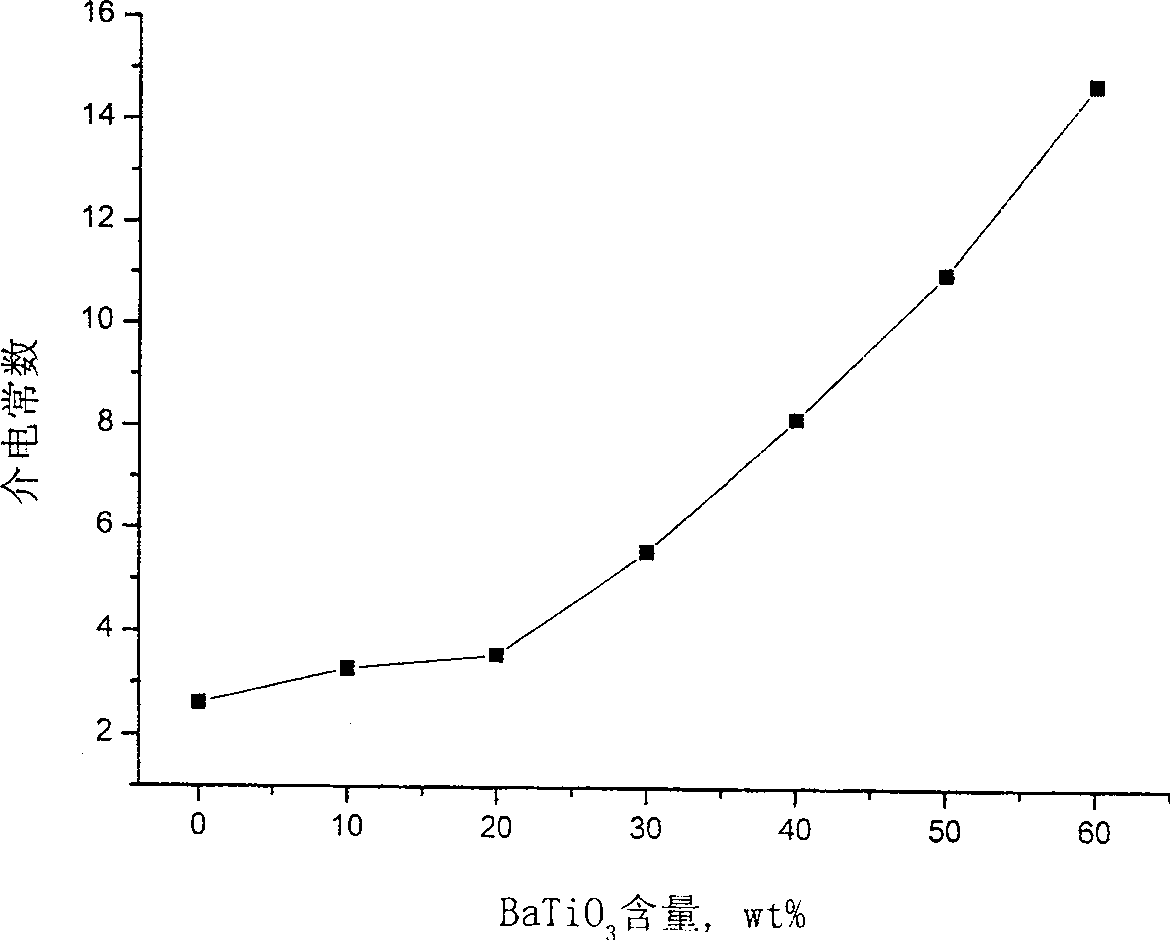

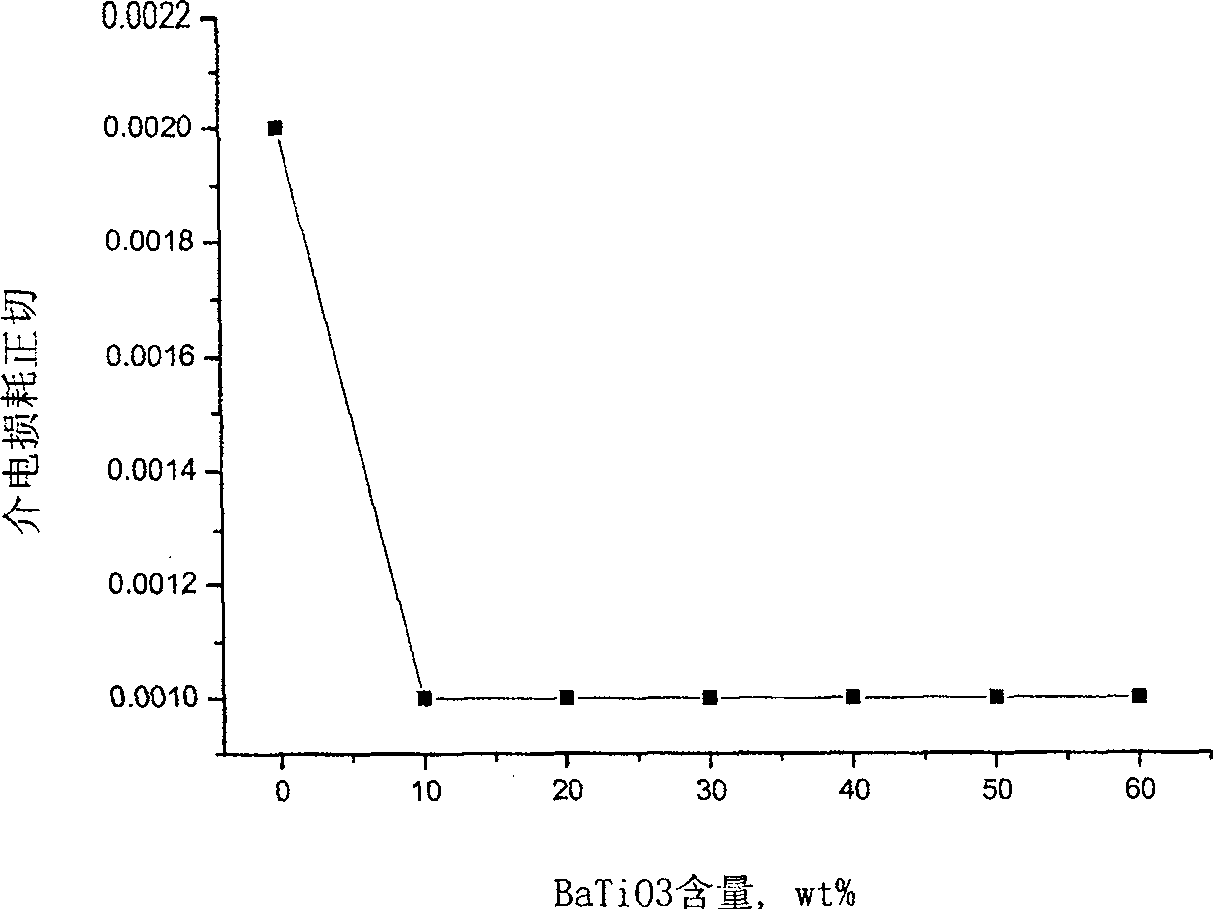

[0027] Inject the composition into a preheated (150°C) mold, degas it in a vacuum oven at 100-105°C for 30 minutes, and cure it according to the process of 160°C / 2h+180°C / 2h+200°C / 2h. According to the process of 230℃ / 5h for post-treatment, BADCy / BaTiO can be obtained 3 composite material. The dielectric properties of each sample at 1KHz are as attached figure 2 And attached image 3 shown. It can be seen that the dielectric constant of the material varies with the BaTiO in the system 3 content increases, when BaTiO 3 Wh...

Embodiment 8 9

[0033] Combine 35g BADCy and 15g BaTiO 3 (400 mesh) mixing, the mixture is heated and melted in an oil bath at 100°C, and then heated to 130°C for pre-curing for 8 hours to BaTiO 3 Without obvious sedimentation, an organic / inorganic binary composition with adjustable dielectric constant and low dielectric loss is obtained.

[0034] The composition is injected into a mold preheated at 150°C, degassed in a vacuum oven at 100-105°C for 30 minutes, and cured according to the process of 160°C / 2h+180°C / 2h+200°C / 2h, and finally Post-treatment is carried out according to the process of 220°C / 1h or 220°C / 1h+230°C / 4h respectively. The dielectric properties of the obtained samples are shown in Table 2. It can be seen that when the curing degree of the material is about 100%, the dielectric constant of the material can be realized by changing the post-treatment process of the material. In addition, the dielectric loss tangent of the material decreases further with subsequent processing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com