Compressor bearing liner

A technology for compressors and bearing bushes, applied in the field of bearing bushes, can solve the problems of large and heavy products, and achieve the effects of small size, good friction compatibility and good embedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

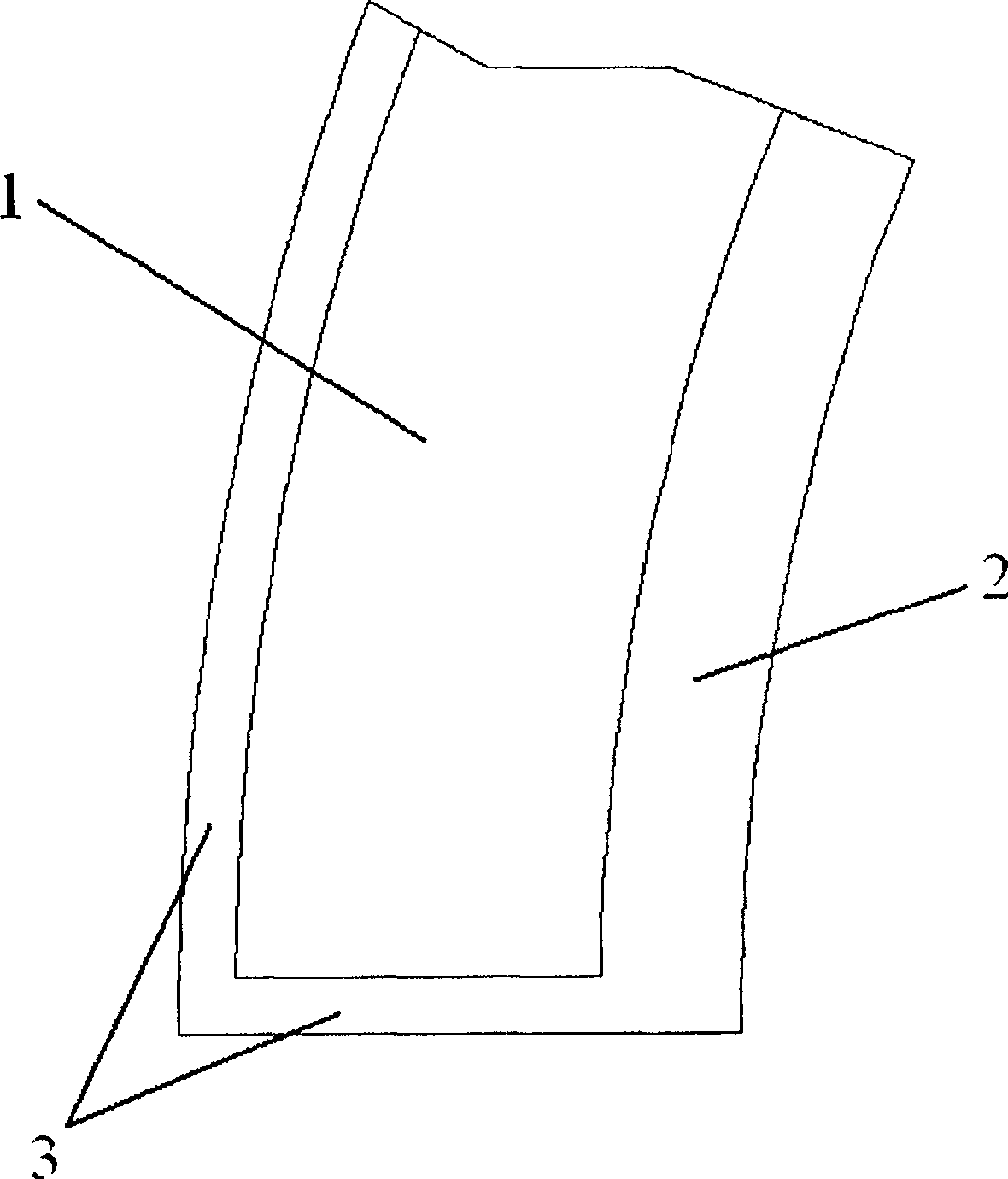

[0011] The structure of the compressor bearing bush according to the present invention can be seen in the accompanying drawings, including the body 1 and the coating on the surface of the body, wherein the thickness of the coating 2 on the inner wall surface of the bearing bush body is greater than that on the inner wall of the bearing bush body. Coating 3 on the surface of other parts.

[0012] The composition of the body includes 5.5%-7% tin, 0.7%-1.3% copper, 0.7%-1.3% nickel, 0.5%-0.9% silicon, 0.1%-0.5% magnesium, and the rest is aluminum. The present invention adopts aluminum-based material as the body of the bearing bush. Aluminum has higher mechanical properties, thermal conductivity and good corrosion resistance. Compared with traditional steel-based Babbitt alloy materials, aluminum-based materials are harder, so they are used as For bearing pads, under the condition of meeting the same technical requirements, the volume of bearing pads made of aluminum-based materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com