Complex reduction method for preparing highly alloyed Pt-based compound metal nano catalyst

A nano-catalyst and composite metal technology, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It is difficult to achieve satisfactory levels and other problems, to achieve excellent electrocatalytic performance, good uniformity and dispersion, and the effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Weigh 60mg of Cabot’s Vulcan XC-72R activated carbon powder, add 1.32ml of 0.0386mol / L H 2 PtCl 6 solution and 0.52ml 0.09635mol / L RuCl 3 , and then add a mixed solution of tetrahydrofuran and water, and stir at high speed for 20 hours to make the mixture uniform.

[0030] 2. At 10°C, slowly add excess reducing agent solution (NaBH 4 ), and mechanically stirred for 1 hour to completely react the metal salt with the reducing agent.

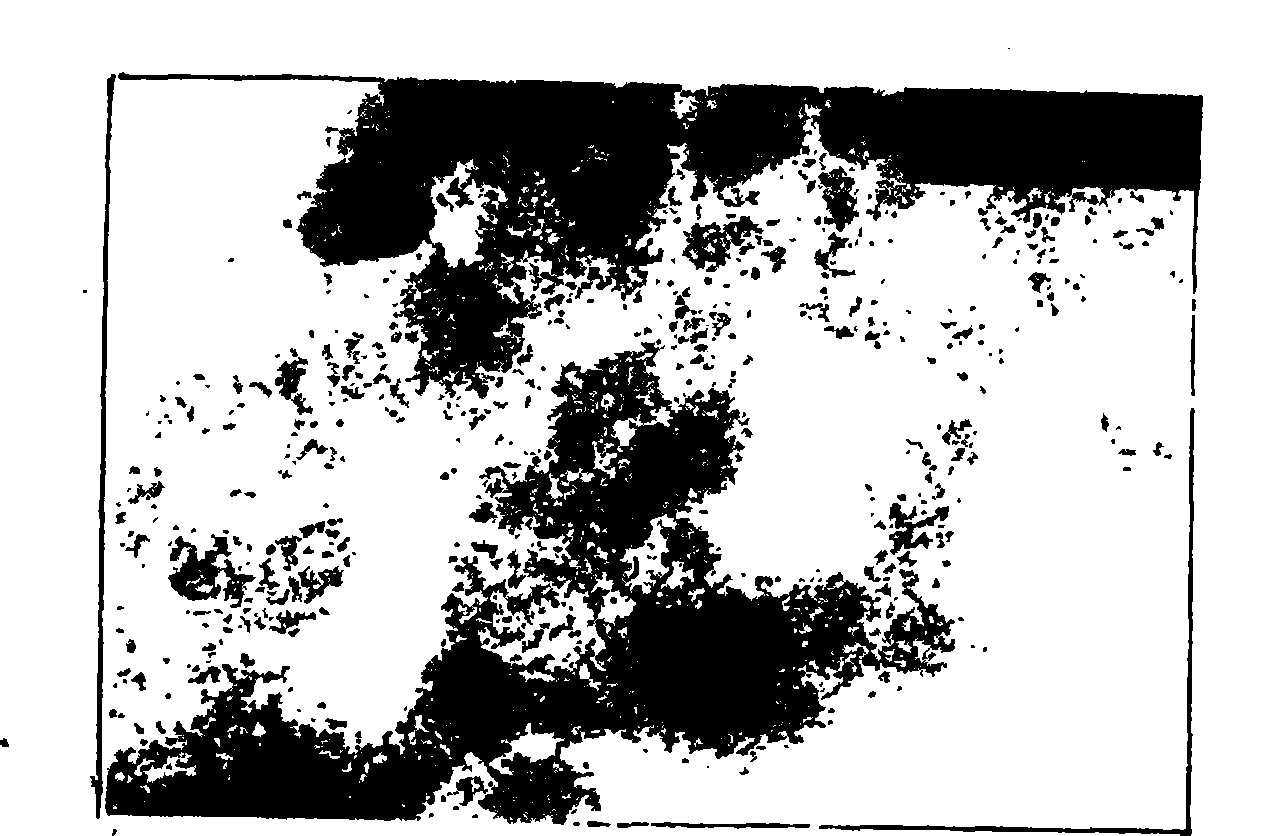

[0031] 3. After drying to remove the solvent, wash with water and alcohol for several times, and check with silver nitrate solution until there is no chloride ion in the eluate. Dry at 60°C under air conditions to obtain a Pt-Ru / C catalyst, in which the particle size of the catalyst is about 1.5-3.5nm.

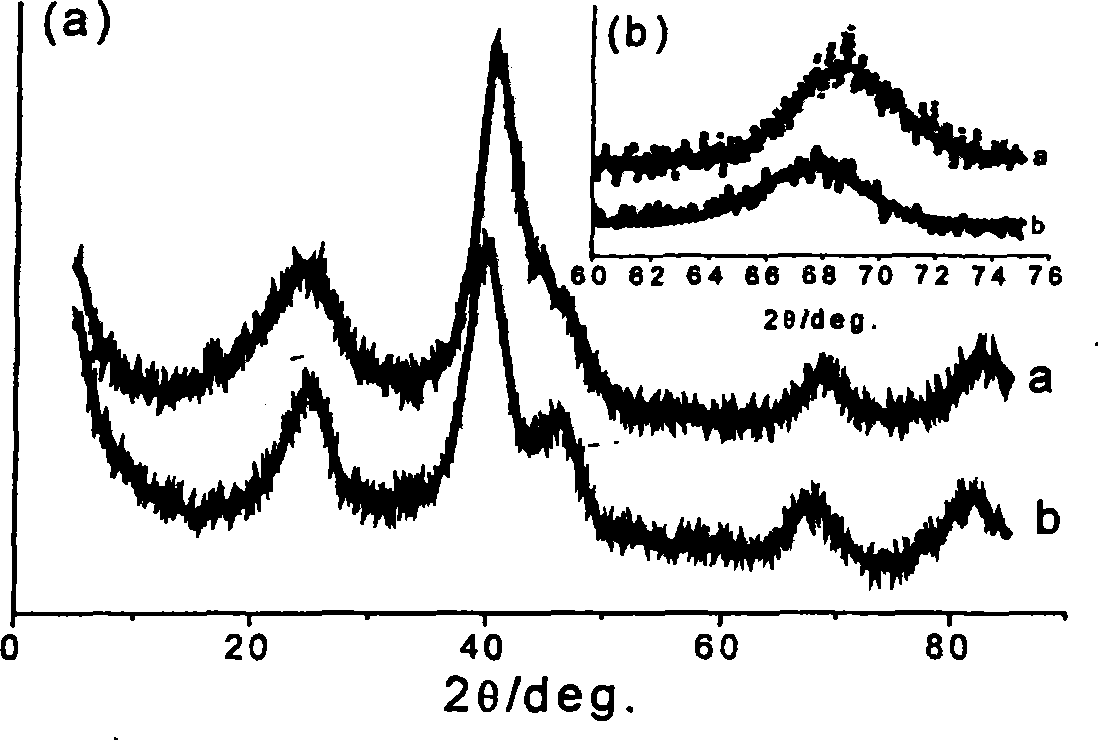

[0032] XRD pattern of homemade PtRu / C catalyst with metal loading of 20% and PtRu atomic ratio of 1:1.

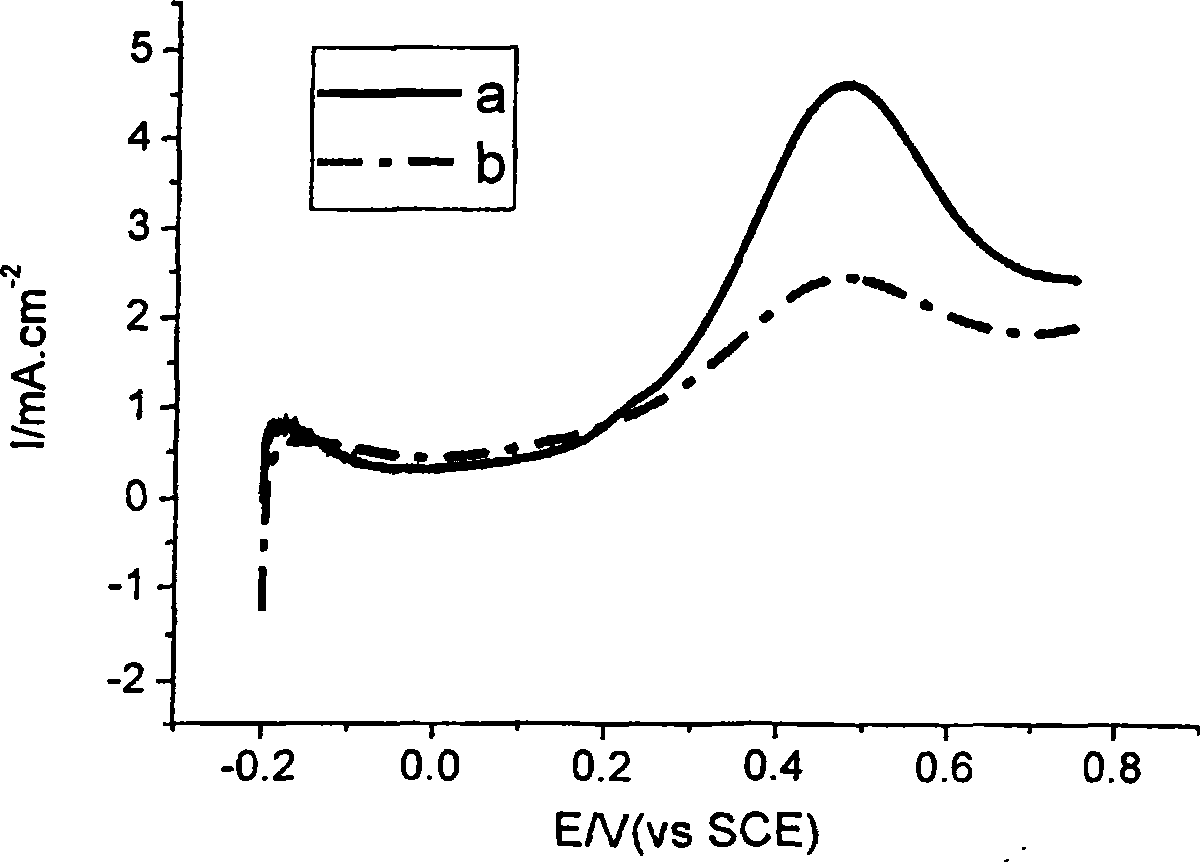

[0033] figure 1It shows that the catalyst has a higher degree of alloying. In the alloy, the atomic fraction of Ru is 46, and t...

Embodiment 2

[0037] 1. Weigh 60mg of self-made carbon nanotubes with a tube diameter of 10-20nm, add 1.32ml of 0.0386mol / LH 2 PtCl 6 solution and 0.52ml0.09635mol / L RuCl 3 , followed by adding a mixed solution of tetrahydrofuran, water and ethanol, and stirring at high speed for 20 hours to make the mixture uniform.

[0038] 2. At 60°C, slowly add excess reducing agent solution (HCOONa), and mechanically stir for 4 hours to completely react the metal salt with the reducing agent.

[0039] 3. After drying to remove the solvent, wash with water and alcohol for several times, and check with silver nitrate solution until there is no chloride ion in the eluate. Dry at 60°C under air condition to prepare Pt-Ru / CNTs catalyst, wherein the particle size of the catalyst is about 1.5-3.5nm.

Embodiment 3

[0041] 1. Weigh 60mg of Cabot's Vulcan XC-72R activated carbon powder, add 1.32ml of 0.0386mol / L H 2 PtCl 6 solution and 0.52ml0.09635mol / L OsCl 3 , and then add a mixed solution of 1,4-dioxane and water, and stir at high speed for 20 hours to make the mixture uniform.

[0042] 2. At 80°C, slowly add excess reducing agent solution (Na 2 S 2 o 4 ), and mechanically stirred for 1 hour to completely react the metal salt with the reducing agent.

[0043] 3. After drying to remove the solvent, wash with water and alcohol for several times, and check with silver nitrate solution until there is no chloride ion in the eluate. The Pt-Os / C catalyst is obtained by drying at 60° C. under vacuum condition, wherein the particle size of the catalyst is about 1.5-3.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com