Method for preparing nano TiO2 polyester ether elastic fiber

A technology of polyether ester elastomer and elastic fiber, which is applied in the field of preparation of nano-TiO2 polyether ester elastic fiber, to achieve the effects of stable chemical properties, uniform fiber size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

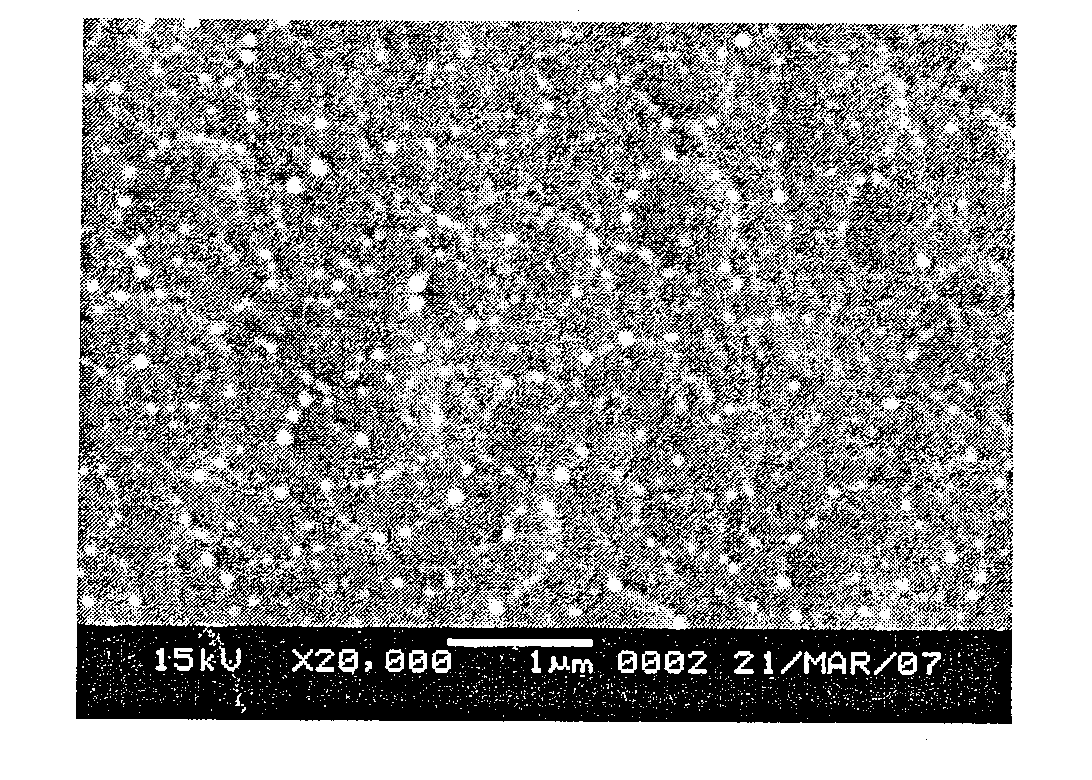

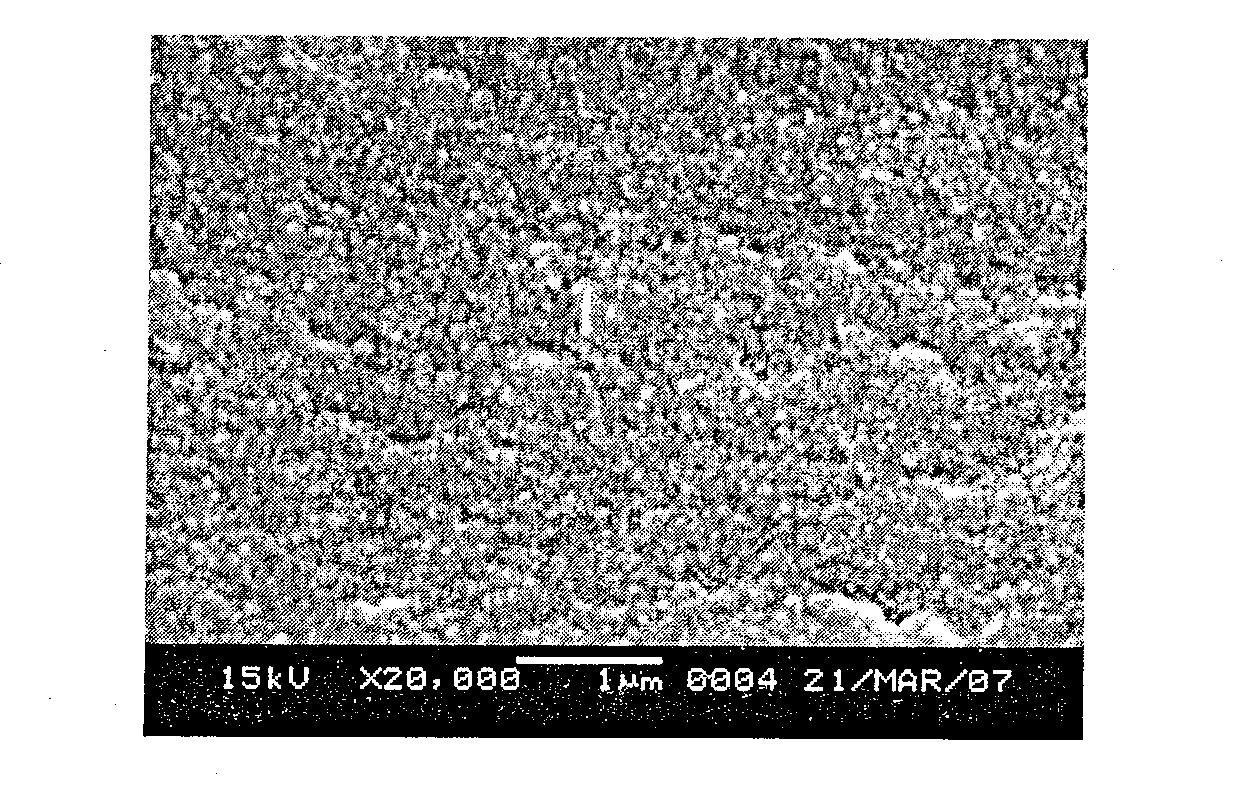

Image

Examples

Embodiment 1

[0029] Using dimethyl terephthalate (DMT), polytetrahydrofuran ether glycol (PTMO), and 1,4-butanediol (BD) as raw materials, adding nano-TiO with a mass fraction of 0.3% 2 Participate in copolymerization, first vacuumize at 100°C to remove water, then raise the temperature to 200°C for transesterification reaction, the transesterification reaction is considered to be complete when the amount of methanol distilled is about 90% of the theoretical amount; raise the temperature to about 250°C, First remove small liquid molecules under low vacuum conditions, then conduct polycondensation reaction for 3 hours while ensuring that the vacuum degree is less than 80Pa, and finally discharge under nitrogen protection to obtain polyether ester elastomers;

[0030] The above polyether ester elastomer was melt spun at a spinning speed of 1000 m / min to obtain polyether ester elastic fibers. Its elastic recovery rate is more than 97% (100% constant elongation) and more than 84% (300% constan...

Embodiment 2

[0032] Using dimethyl terephthalate (DMT), polytetrahydrofuran ether glycol (PTMO), and 1,4-butanediol (BD) as raw materials, adding nano-TiO with a mass fraction of 0.5% 2 Participate in copolymerization, first vacuumize at 100°C to remove water, then raise the temperature to 200°C for transesterification reaction, the transesterification reaction is considered to be complete when the amount of methanol distilled is about 90% of the theoretical amount; raise the temperature to about 250°C, First remove small liquid molecules under low vacuum conditions, then polycondense for 3.5 hours under the condition of ensuring that the vacuum degree is less than 80Pa, and finally discharge under nitrogen protection to obtain polyether ester elastomers;

[0033] The above polyether ester elastomer was melt spun at a spinning speed of 800 m / min to obtain polyether ester elastic fibers. Its elastic recovery rate is more than 97% (100% constant elongation) and more than 86% (300% constant e...

Embodiment 3

[0035] Using dimethyl terephthalate (DMT), polytetrahydrofuran ether glycol (PTMO), and 1,4-butanediol (BD) as raw materials, adding nano-TiO with a mass fraction of 1.0% 2Participate in copolymerization, first vacuumize at 100°C to remove water, then raise the temperature to 200°C for transesterification reaction, the transesterification reaction is considered to be complete when the amount of methanol distilled is about 90% of the theoretical amount; raise the temperature to about 250°C, First remove small liquid molecules under low vacuum conditions, then polycondense for 4 hours under the condition that the vacuum degree is guaranteed to be less than 80Pa, and finally discharge under nitrogen protection to obtain polyether ester elastomers;

[0036] The above polyether ester elastomer was melt spun at a spinning speed of 1000 m / min to obtain polyether ester elastic fibers. Its elastic recovery rate is more than 97% (100% constant elongation) and more than 88% (300% constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com