Rare-earth hybridized in-situ polymerized polyolefinel polypropelene fine denier dyeable fiber resin and preparing method

An in-situ polymerization, polyolefin technology, applied in the direction of conjugated synthetic polymer rayon, etc., can solve the problem of not being able to dye dark colors, achieve excellent anti-ultraviolet and anti-aging functions, improve physical and mechanical properties, and improve dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 100ml absolute ethanol, 10g Y 2 o 3 Nano powder and relative to Y 2 o 3 Nano powder mass 8% C15 titanate coupling agent. Then dry the Y at 100 °C for 2 h 2 o 3 Nanoparticles were gradually added into the flask, ultrasonically oscillated at 25°C and stirred for 30min at the same time. After shaking, heat and reflux at a constant temperature in a water bath at 80°C for 4 hours.

[0038] 6 g of the above-mentioned surface-modified Y 2 o 3 After ultrasonic dispersion of nanoparticles together with 0.7 g of dibenzoyl peroxide (BPO) and 80 g of modified olefin monomers, 4 g of polyvinyl alcohol (PVA) and 0.2 g of Na 2 S 2 o 3 In 250 ml of deionized water, react at 75°C for 1 hour, raise the temperature to 80°C for 1.5 hours, raise the temperature to 90°C for 1.5 hours, raise the temperature to 95°C, and harden the particles for 2 hours.

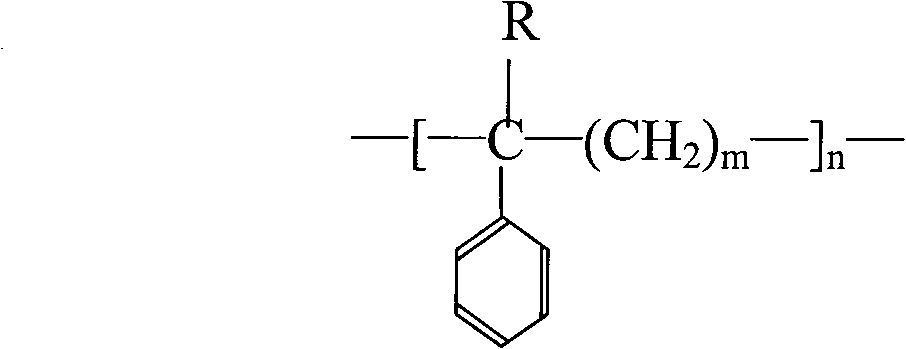

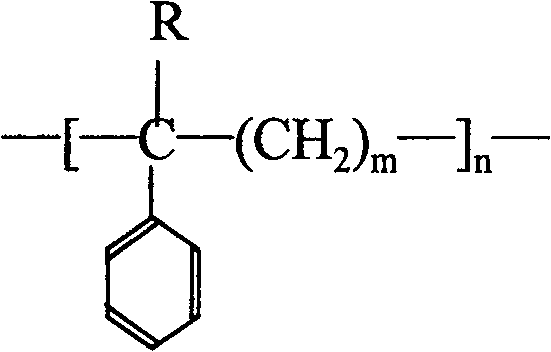

[0039]The general structural formula of the modified polyolefin is as formula 1, wherein, R is H, m=1, n=360.

[0040] Fina...

Embodiment 2

[0045] Add 100ml of isopropanol and 15g of Y to a 250ml three-necked flask 2 o 3 Nano powder and relative to Y 2 o 3 Nano powder mass 12% C20 titanate coupling agent. Then dry the Y at 100 °C for 2 h 2 o 3 Nanoparticles were gradually added to the flask, at room temperature, ultrasonically oscillated and stirred for 30min at the same time. After shaking, heat and reflux at a constant temperature in a water bath at 80°C for 4 hours.

[0046] 10 grams of the above-mentioned surface-modified Y 2 o 3 Nanoparticles together with 1.25 grams of dibenzoyl peroxide (BPO) and a mixed suspension of 100 grams of modified olefin monomers were ultrasonically dispersed, and 6 grams of dispersant polyvinyl alcohol (PVA) and 0.2 grams of Na 2 S 2 o 3 In 250 ml of deionized water, react at 75°C for 1 hour, raise the temperature to 80°C for 1.5 hours, raise the temperature to 90°C for 1.5 hours, raise the temperature to 95°C, and harden the particles for 2 hours.

[0047] The general ...

Embodiment 3

[0053] Add 100ml absolute ethanol, 12g Y 2 o 3 Nano powder and relative to Y 2 o 3 Nano powder mass 16% C10 titanate coupling agent. Then dry the Y at 100 °C for 2 h 2 o 3 Nanoparticles were gradually added to the flask, at room temperature, ultrasonically oscillated and stirred for 30min at the same time. After shaking, heat and reflux at a constant temperature in a water bath at 80°C for 4 hours.

[0054] 8 g of the above-mentioned surface-modified Y 2 o 3 Nanoparticles together with 1.05 grams of dibenzoyl peroxide (BPO) and 100 grams of modified olefin monomer suspension ultrasonic dispersion, adding 8 grams of dispersant polyvinyl alcohol (PVA) and 0.2 grams of Na 2 S 2 o 3 In 250 ml of deionized water, react at 75°C for 1 hour, raise the temperature to 80°C for 1.5 hours, raise the temperature to 90°C for 1.5 hours, raise the temperature to 95°C, and harden the particles for 2 hours.

[0055] The general structural formula of the modified polyolefin is as form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com