Method for preparing lead zirconate titanate ceramics fibre

A technology of lead zirconate titanate and ceramic fiber, applied in the field of ceramic fiber, can solve the problems of complex structure, difficult control, high toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1), 5.8018 grams of Pb (OOCH 3 ) 2 ·3H 2 O was added to 20ml of n-butanol, after shaking well, 12.85ml of glacial acetic acid was added, and the mixed solution was heated to 80°C until Pb(OOCH 3 ) 2 ·3H 2 O was completely dissolved to obtain a colorless clear solution, which was cooled to room temperature to obtain a lead source solution. Add 3.74ml of zirconium butoxide and 2.53ml of titanium butoxide into 20ml of n-butanol in sequence, stir magnetically for half an hour, add 3.09ml of acetylacetone, stir for half an hour, and then reflux the mixed solution at 75°C for one hour. After cooling, zirconium source and titanium source solutions are obtained. Mix the above-mentioned lead source solution with zirconium and titanium source solutions at room temperature, and then reflux at 120° C. for one hour. The obtained yellow transparent solution is the PZT precursor solution, and the pH value of the solution is 3.5-3.9.

[0031] (2) The precursor solution was magne...

Embodiment 2

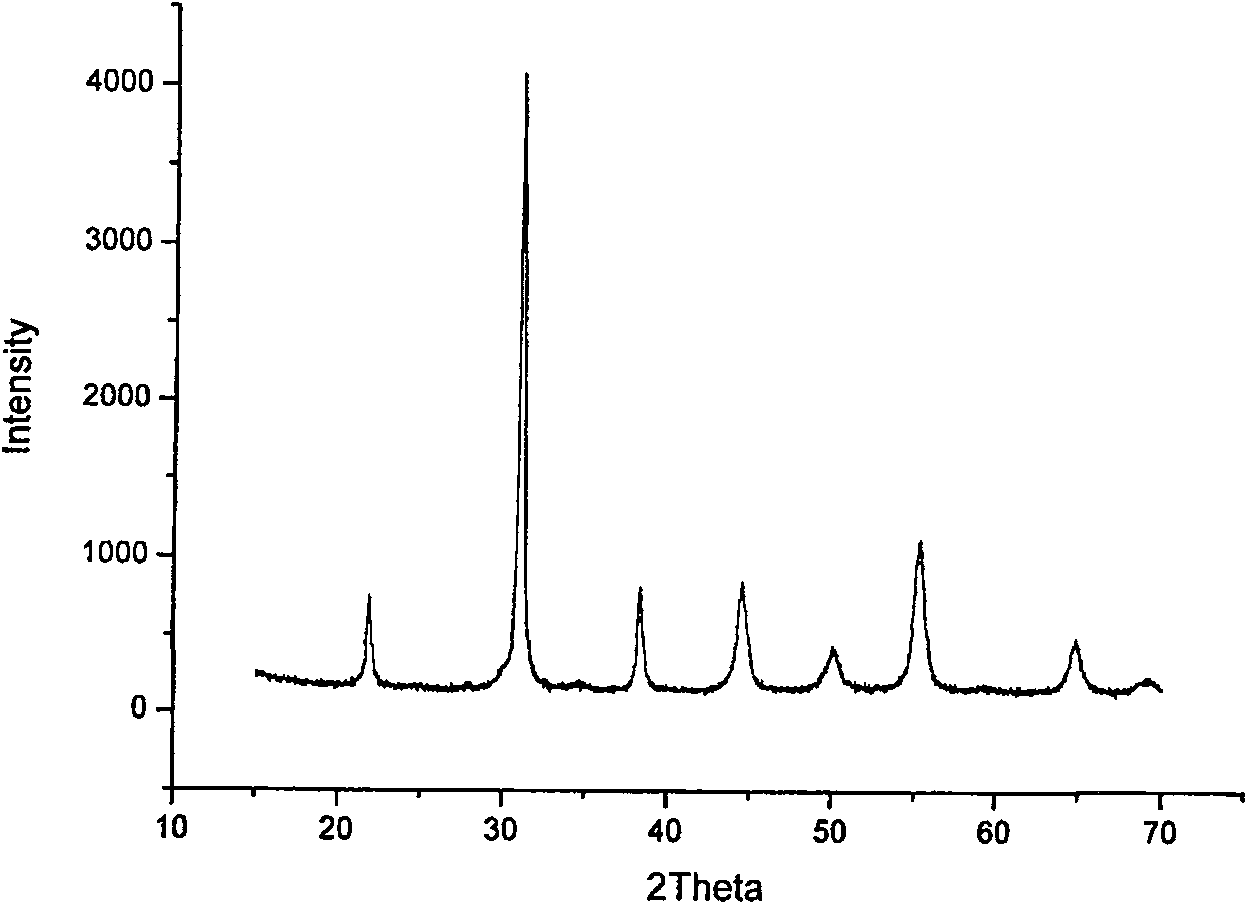

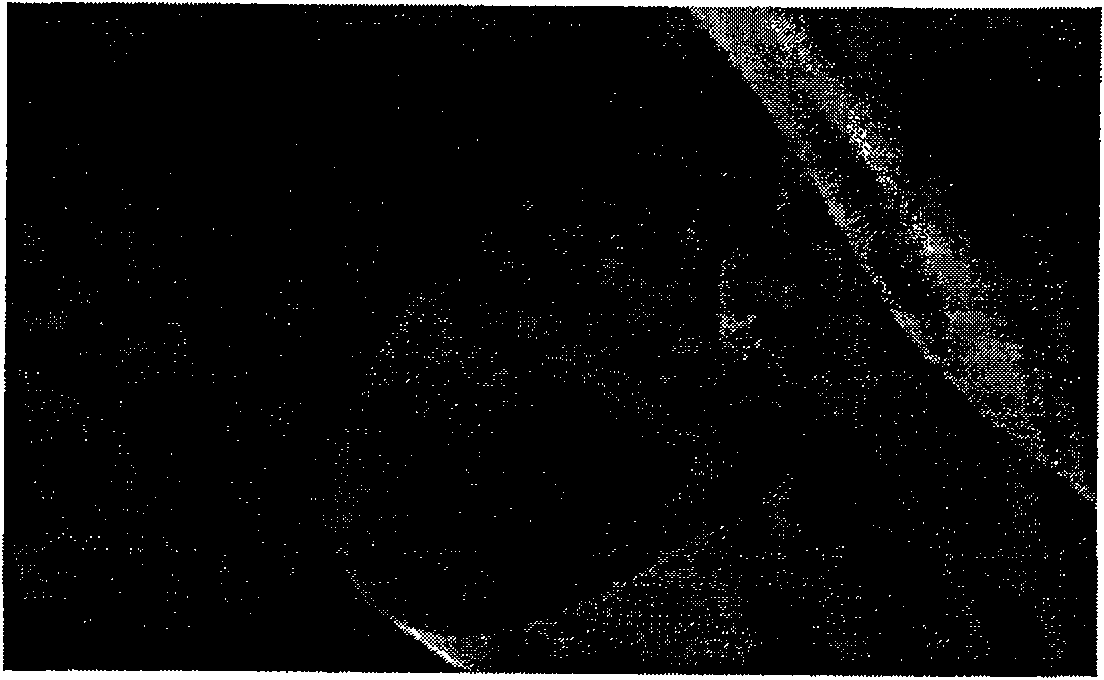

[0034] Example 2: Same as Example 1, the difference is that when the sintering temperature is 900° C., the obtained PZT ceramic fiber surface has fine grains (<0.5 μm), and the surface is relatively smooth and flat.

Embodiment 3

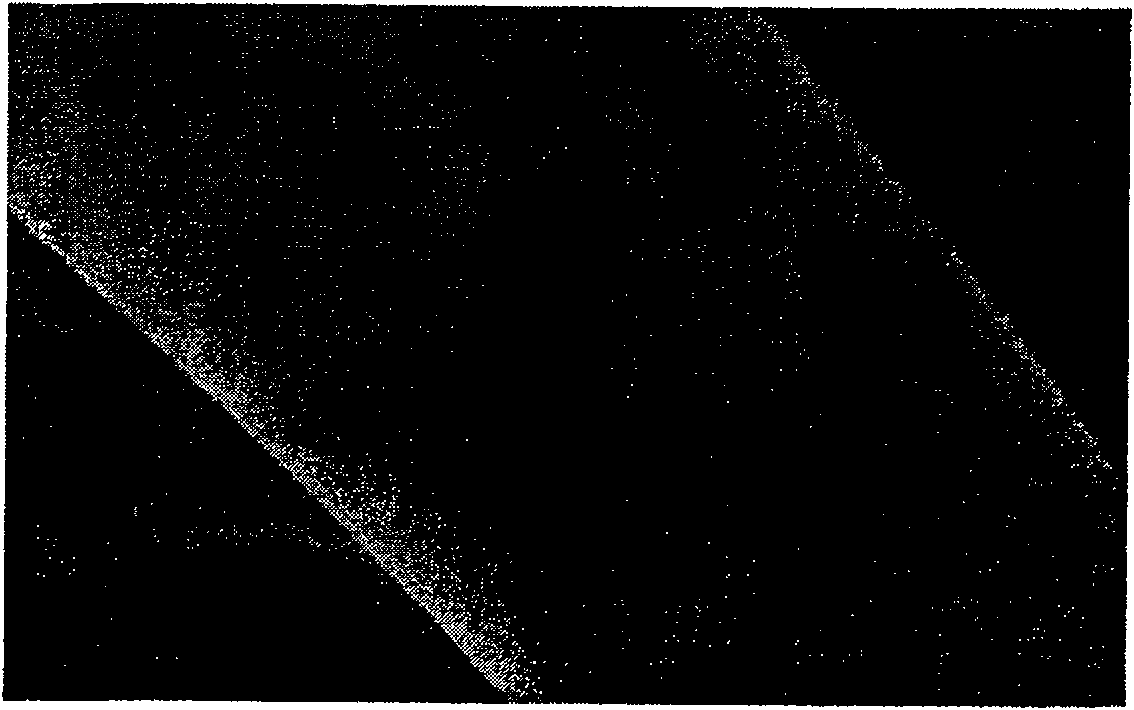

[0035] Embodiment 3: Same as Embodiment 1, the difference is that when the sintering temperature is 1000° C., the obtained PZT ceramic fiber has surface grains smaller than 1 μm, and the surface is relatively rough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com