Method for preparing metallic simple substance nano-crystal material

A technology of nanocrystals and simple metals, applied in the field of preparation of a method, to achieve the effects of eliminating pollution, easy surface modification, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

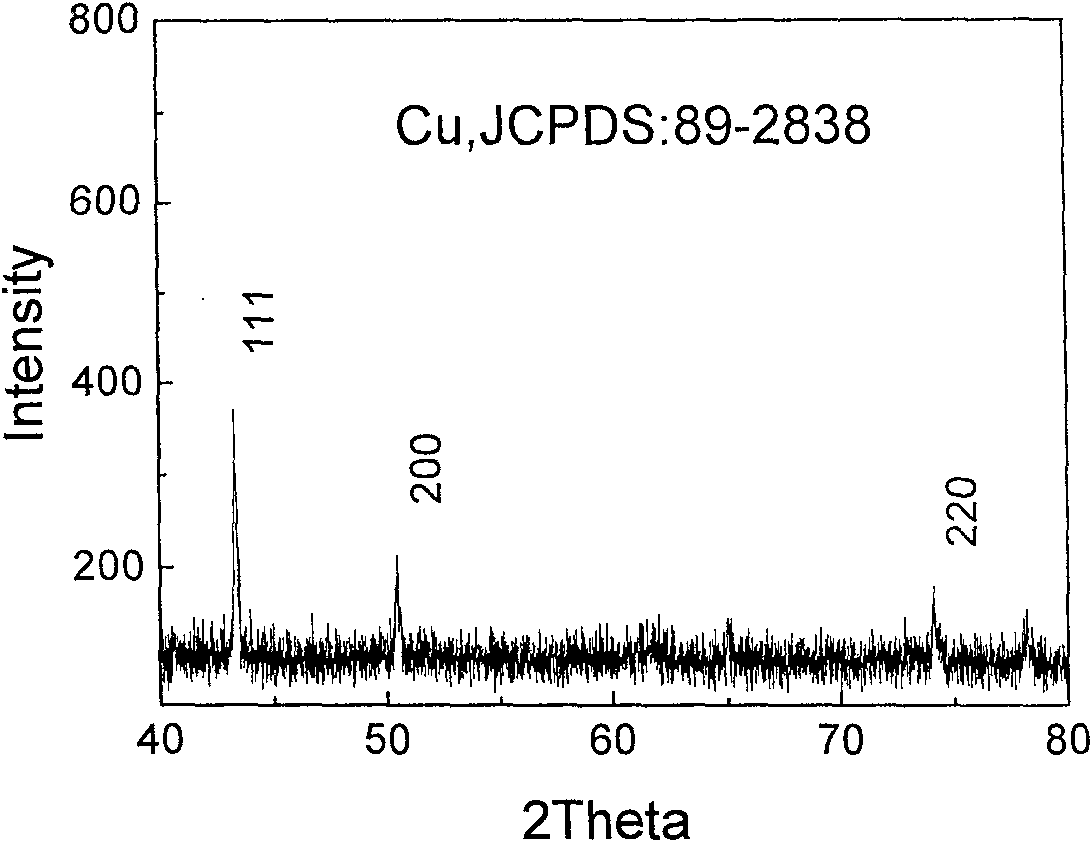

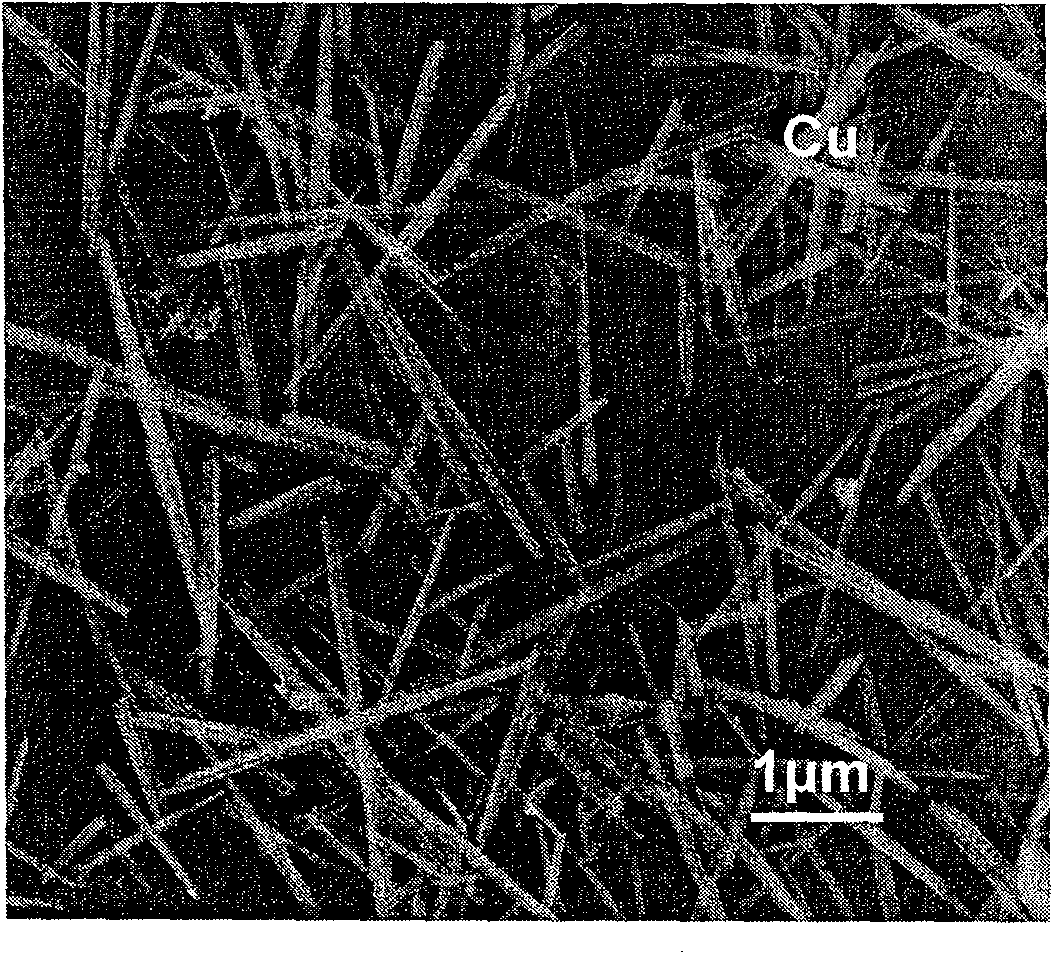

[0025] The specific synthetic method of copper nanocrystal material

[0026] The raw materials for the synthesis of copper nanocrystal materials are KOH, NaOH, copper chloride (CuCl 2 .2H 2 O), iron powder, the step-by-step reaction that takes place is as follows:

[0027] (a) CuCl 2 .2H 2 O→Cu + +2Cl - +2H 2 o

[0028] (b) Fe+2NaOH→FeO+H 2 +Na 2 o

[0029] (c)H 2 +Cu 2+ +2OH - →Cu+2H 2 o

[0030] The specific operation steps are as follows:

[0031] Step 1. KOH=57% and NaOH=43% are weighed and mixed according to the weight percentage as the reaction solvent.

[0032] Step 2, press copper chloride (CuCl 2 .2H 2 O) % by weight = 23%, % by weight of zinc powder = 77% weighed as a reactant. The weight percent of reactants to reactants+reaction solvent was 8.1%.

[0033] Step 3, put the reaction raw materials of the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, the weight percentage of the reactant ...

Embodiment 2

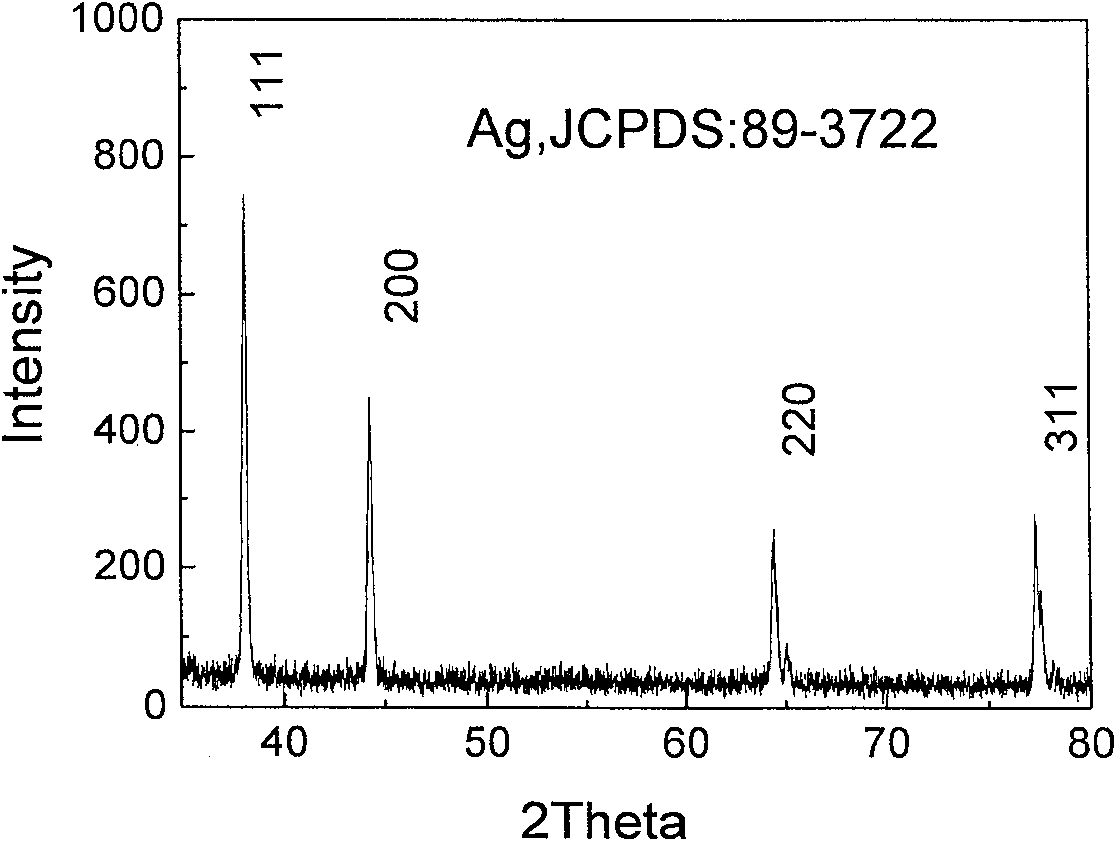

[0038] Synthesis of silver nanocrystal structures

[0039] The raw materials for synthesizing silver nanocrystal materials are KOH, NaOH, silver nitrate (AgNO 3 ), zinc powder, the step-by-step reaction that takes place is as follows:

[0040] (a) AgNO 3 → Ag + +NO 3 -

[0041] (b)Zn+2NaOH→ZnO+H 2 +Na 2 o

[0042] (c)H 2 +2Ag + +2OH - →2Ag+2H 2 o

[0043] The specific operation steps are as follows:

[0044] Step 1. KOH=57% and NaOH=43% are weighed and mixed according to the weight percentage as the reaction solvent.

[0045] Step 2, press silver nitrate (AgNO 3 ) weight percent=72.2%, zinc weight percent=27.8% were weighed as reactant.

[0046] Step 3, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, the weight percentage of the reactant is 4.6%, then the polytetrafluoroethylene container is sealed and put into the temperature Inside a constant temperature muffle f...

Embodiment 3

[0051] Synthetic method of lead (Pb) nanocrystal material

[0052] The raw materials for the synthesis of lead nanocrystal materials are KOH, NaOH, lead nitrate (Pb(NO 3 ) 2 ), zinc powder, the step-by-step reaction that takes place is as follows:

[0053] (a)Pb(NO 3 ) 2 →Pb 2+ +2NO 3 -

[0054] (b)Zn+2NaOH→ZnO+H 2 +Na 2 o

[0055] (c)H 2 +Pb 2+ +2OH - →Pb+2H 2 o

[0056] The specific operation steps are as follows:

[0057] Step 1. KOH=57% and NaOH=43% are weighed and mixed according to the weight percentage as the reaction solvent.

[0058] Step 2, according to lead nitrate (Pb(NO 3 ) 2 ) weight percent=42%, zinc weight percent=58% weighed as reactant.

[0059] Step 3, put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, the weight percentage of the reactant is 4.1%, then the polytetrafluoroethylene container is covered and closed and put into the temperature Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com