Hot-melt asphalt adhesive and its production

A technology of adhesives and asphalt, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve the problems of slow bonding speed and low viscosity of emulsified asphalt, and achieve fast bonding speed, simple production process, durable good impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of base asphalt: put the raw material of road petroleum asphalt (penetration = 701 / 10mm) into the reaction kettle, heat it, feed oxygen at 245°C, and react for 12 hours to make oxidized asphalt, which is the base asphalt. The properties of the obtained base pitch are as follows: the penetration is 241 / 10mm, and the softening point is 68°C.

Embodiment 2

[0035] Composition of hot melt asphalt adhesive:

[0036] Base bitumen 100 parts

[0037] 4 copies of SBS

[0038] 6 parts petroleum resin

[0039] Aluminum oxide 15 parts

[0041] Sublimed sulfur 0.12 parts

[0042] Its preparation process is as follows:

[0043] Add the above-mentioned weighed base asphalt, SBS, and petroleum resin into the reaction kettle, heat to 175°C, stir for 2 hours at a stirrer speed of 4000 rpm, and then add alumina, Silicon oxide and cross-linking agent, continue to stir for 2 hours, the stirring speed is 2000 rpm, after the stirring process is completed, the material can be discharged, cooled to room temperature, and the target product is obtained. The resulting product has moderate and stable viscosity, and its properties are shown in Table 1.

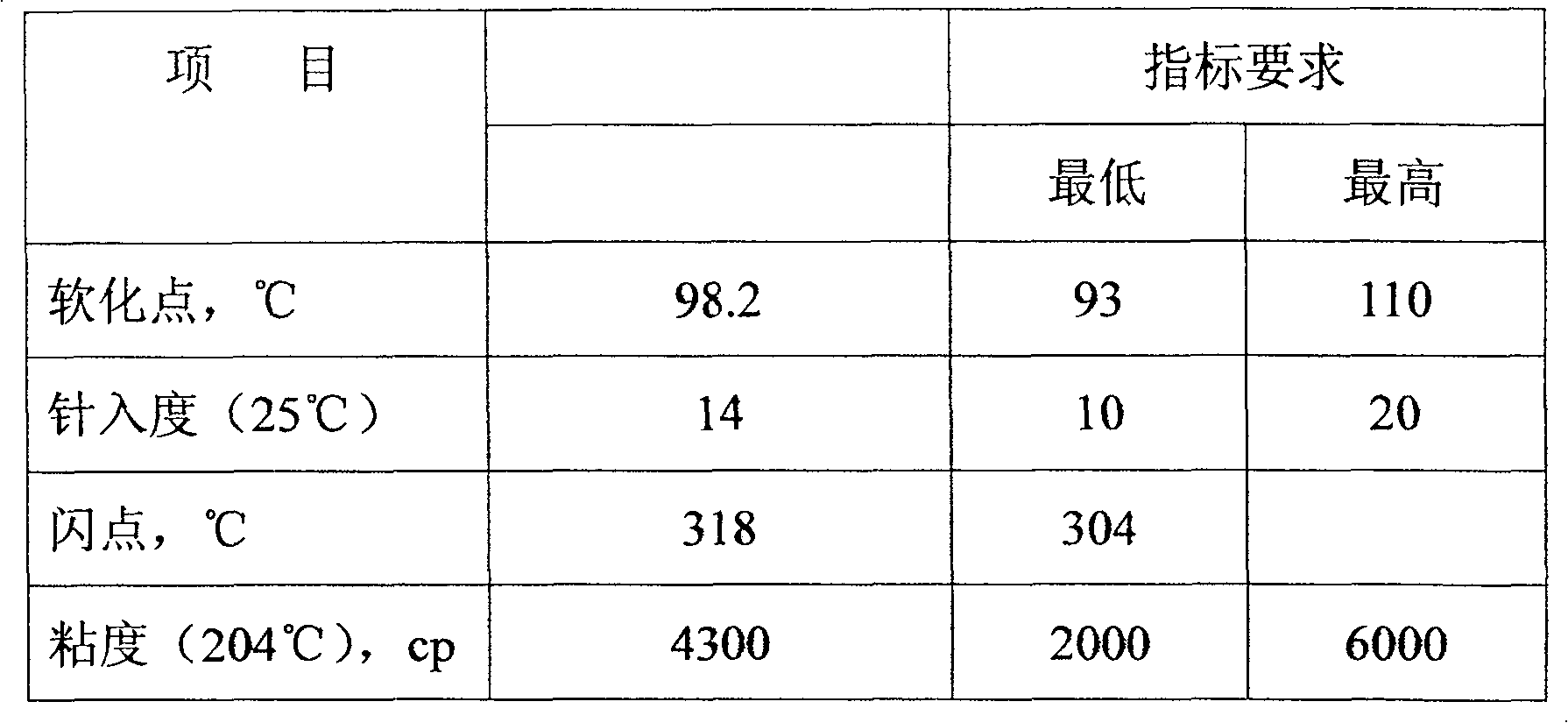

[0044] Table 1 Hot melt asphalt adhesive

[0045]

Embodiment 3

[0047] Composition of hot melt asphalt adhesive:

[0048] Base bitumen 100 parts

[0049] 5 copies of SBS

[0050] 2 parts petroleum resin

[0051] Aluminum oxide 30 parts

[0052] Silicon oxide 2 parts

[0053] Sublimed sulfur 0.14 parts

[0054] Its preparation process is as follows:

[0055] Add the above-mentioned weighed base asphalt, SBS, and petroleum resin into the reaction kettle, heat to 160°C, stir for 40 minutes at a stirrer speed of 6000 rpm, and then add alumina, Silicon oxide and cross-linking agent, continue to stir for 4 hours, the stirring speed is 800 rpm, after the stirring process is completed, the material can be discharged, cooled to room temperature, and the target product is obtained. The resulting product has moderate and stable viscosity, and its properties are shown in Table 2.

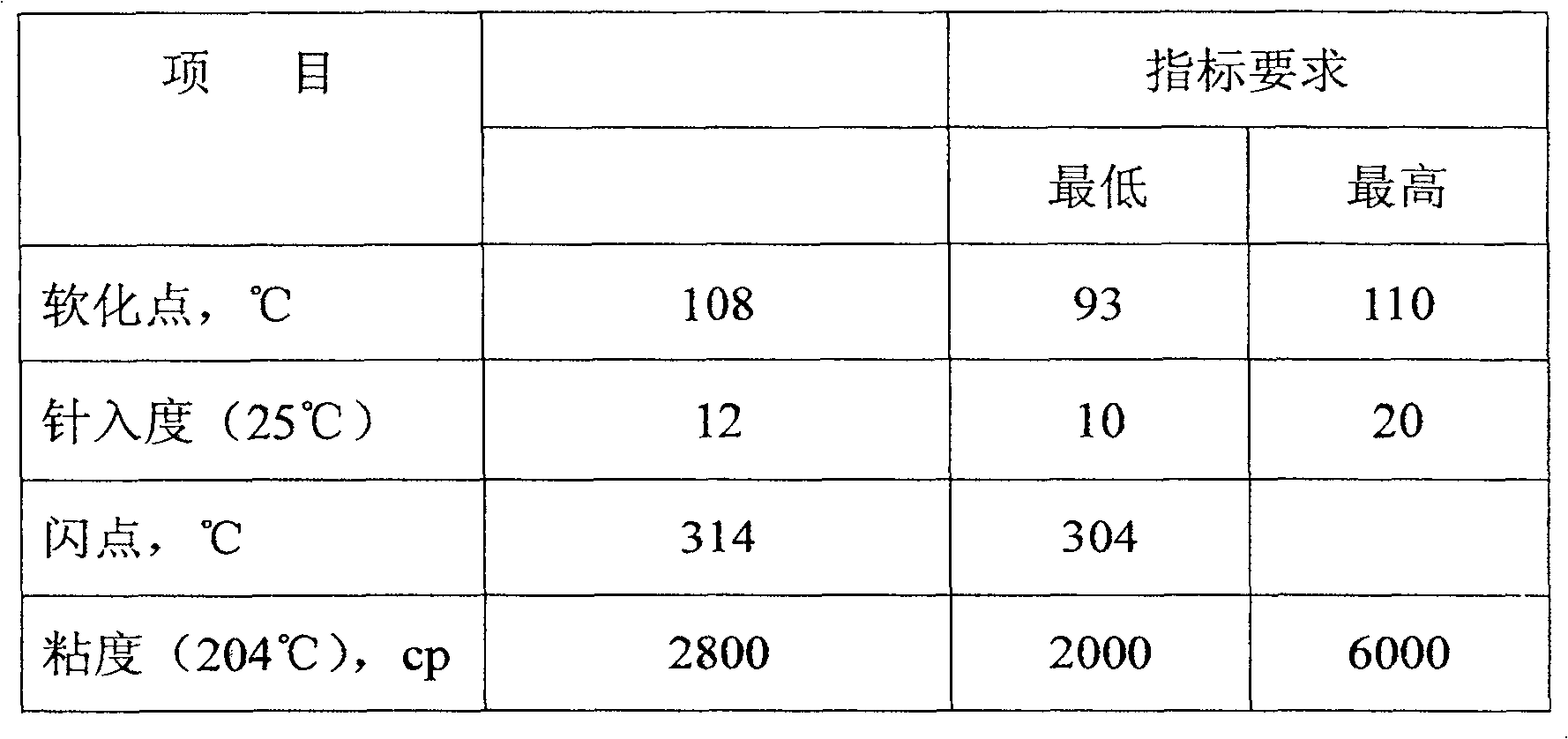

[0056] Table 2 Hot melt asphalt adhesive

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com