Process for extracting n-heptane for combined production of octane product by pressure swing adsorption

A pressure swing adsorption, n-heptane technology, applied in adsorption purification/separation, organic chemistry, distillation purification/separation, etc. High-purity n-heptane, few reports on production processes, etc., to achieve the effect of improving resource utilization efficiency, good economic value and social benefits, and extremely market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

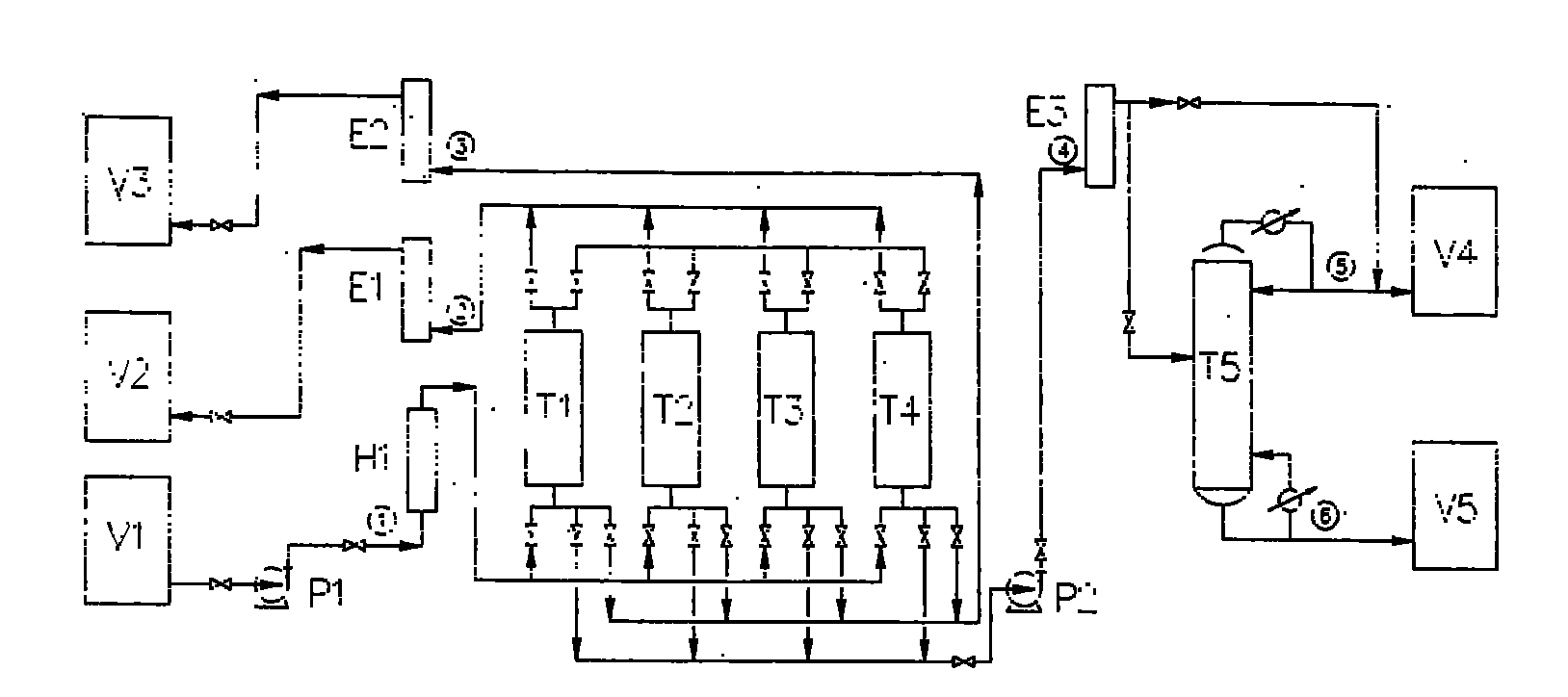

[0018] Embodiment 1: Adopt No. 120 solvent oil as raw material, SAPO-34 molecular sieve is adsorbent, the typical composition of No. 120 solvent oil is shown in Table 1, and the schematic diagram of four-tower pressure swing adsorption process is as follows figure 1 shown.

[0019] Table No. 1120 solvent oil composition

[0020]

[0021] The four-tower (T1, T2, T3, T4) pressure swing adsorption cycle process and time distribution are shown in Table 2. A pressure swing adsorption cycle period is 16 minutes, of which the adsorption is 4 minutes, the average pressure drop is 2 minutes, the pressure is released for 2 minutes, and the desorption is 4 minutes. The pressure is raised for 2 minutes, and the pressure is charged for 2 minutes.

[0022] Table 2 Four-tower pressure swing adsorption cycle process and time distribution

[0023]

[0024]

[0025] [Note]: A-adsorption, ED-pressure drop, CD-decompression, V-desorption, ER-pressure rise, R-charge.

[0026] Schematic...

Embodiment 2

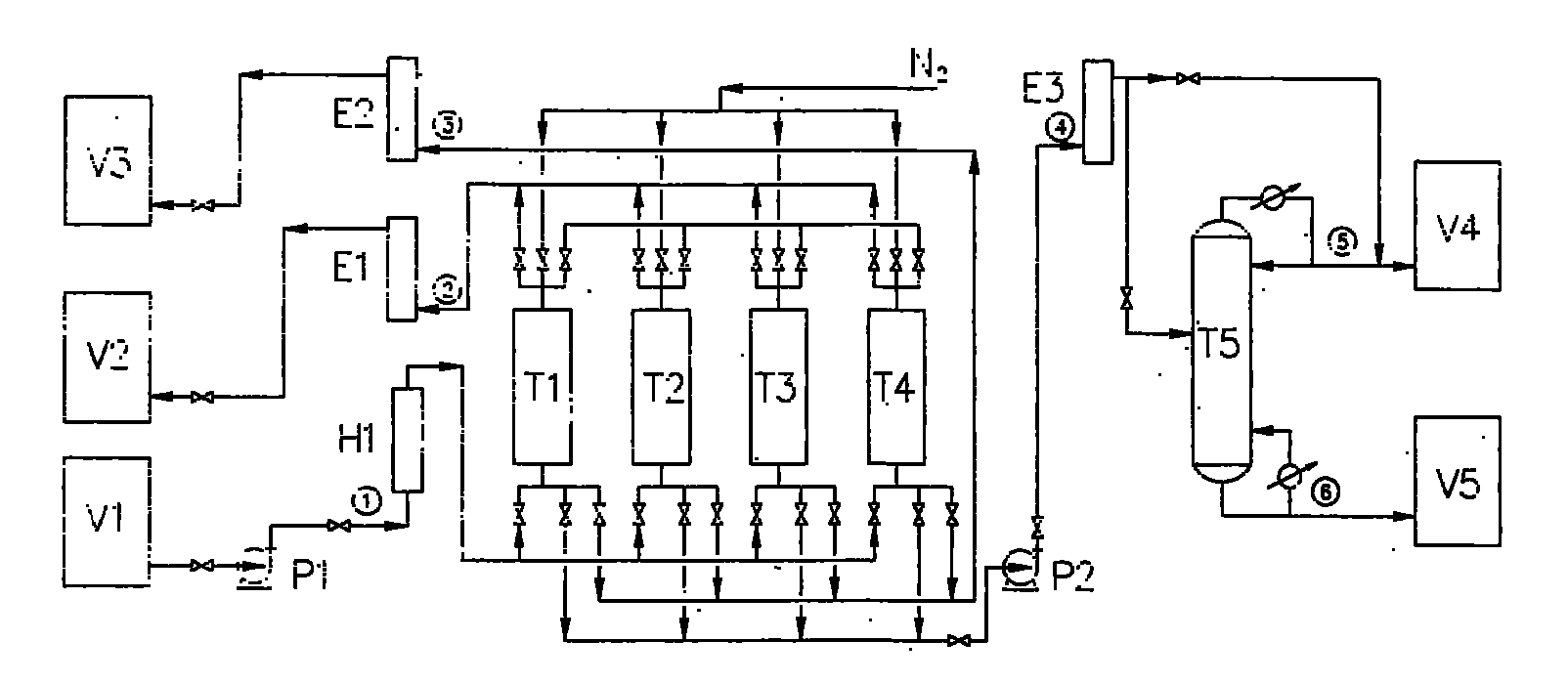

[0027] Example 2, such as figure 2 shown. The pressure swing adsorption process, specific operation process and steps are the same as in Example 1, the difference is that the adsorption temperature is 160°C, and the desorption adopts vacuuming while using N 2 Purging, desorption pressure is 40kPa.

Embodiment 3

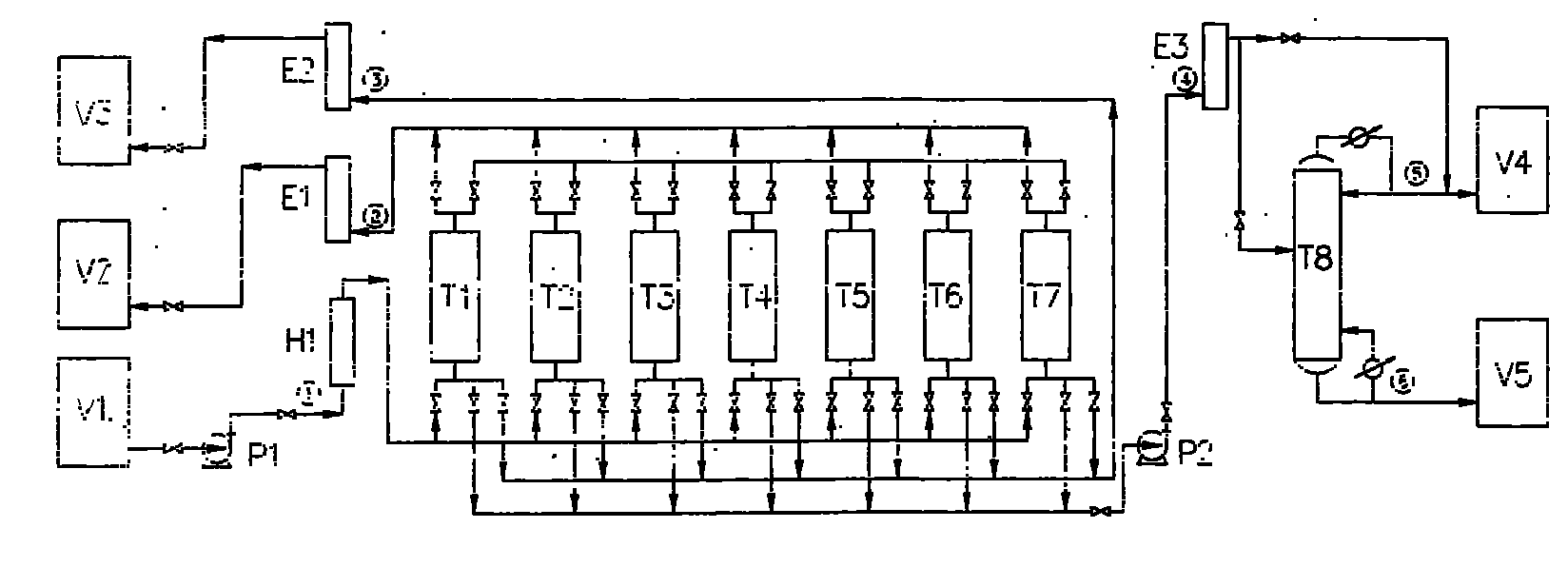

[0028] Embodiment 3, using reformed raffinate as raw material, 5A molecular sieve as adsorbent, the composition of reformed raffinate is shown in Table 3, and the schematic diagram of the seven-tower pressure swing adsorption process is as follows image 3 shown.

[0029] Table 3 Composition of reformed raffinate

[0030]

[0031] The seven towers (T1, T2, T3, T4, T5, T6, T7) pressure swing adsorption cycle process and time distribution are shown in Table 4. One pressure swing adsorption cycle is 21 minutes, of which the adsorption is 6 minutes, and the first and third are both 2min, release pressure for 2min, and desorb for 3min.

[0032] Table 4 Seven-tower pressure swing adsorption cycle process and time distribution

[0033]

[0034] [Note]: A-adsorption, ED1-one average pressure drop, ED2-two average pressure drop, ED3-three average pressure drop, CD-depressurization, V-desorption, ER1-average pressure rise, ER2-two average pressure rise , ER3-three equal pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com