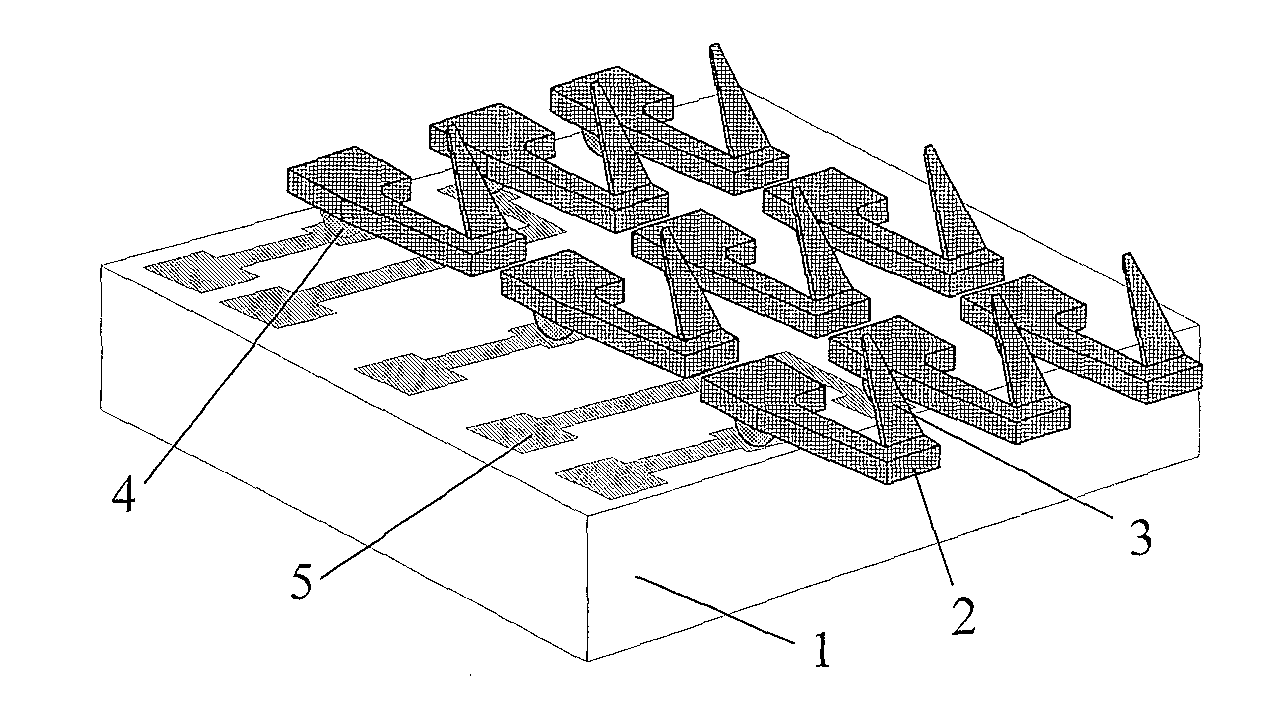

Micro-mechanism testing probe card based on electroplating technique and manufacturing method thereof

An electroplating process and micro-mechanical technology, applied in the direction of electronic circuit testing, process for producing decorative surface effects, metal material coating process, etc., can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

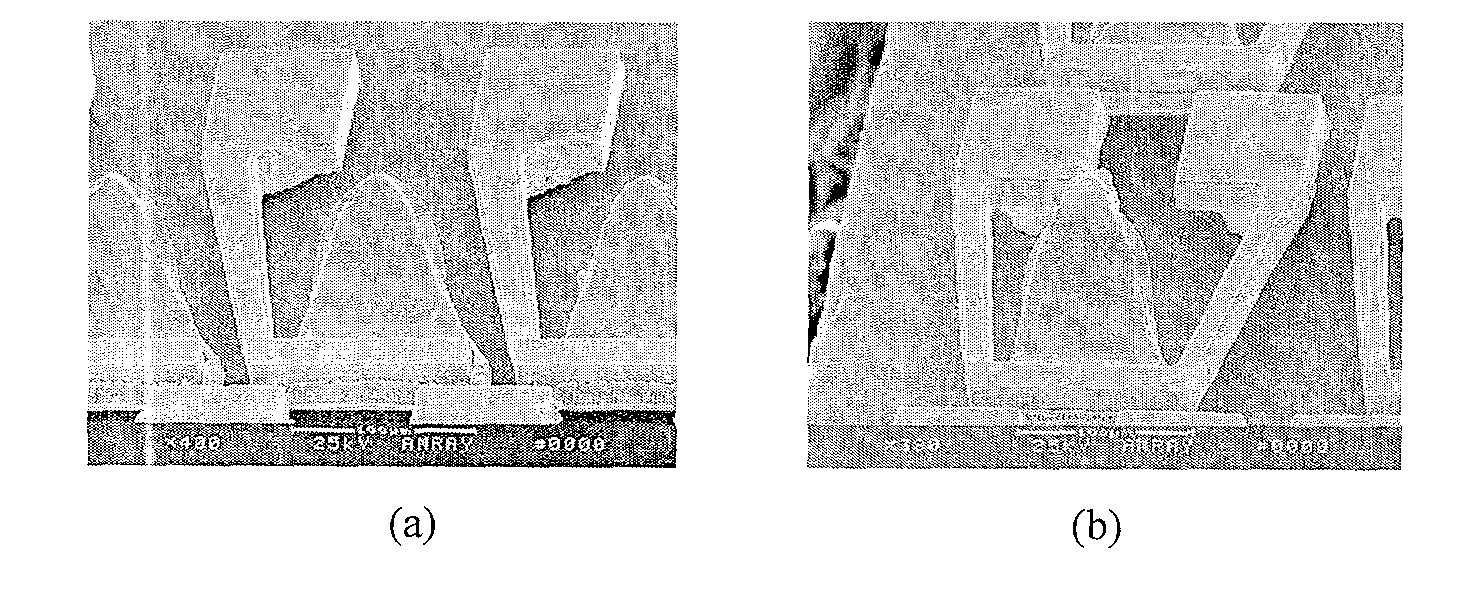

Examples

Embodiment 1

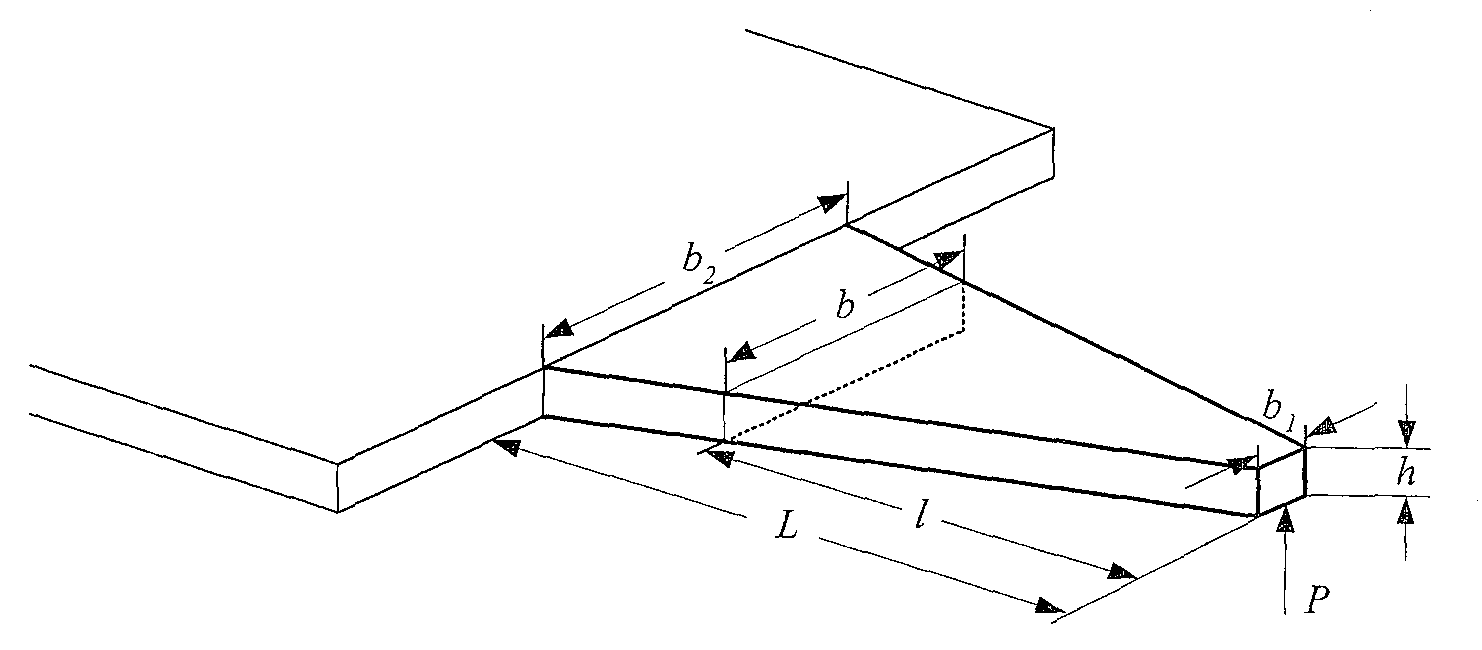

[0043] a Deposit or oxidize a layer of 0.5-2.5 μm oxide layer on the (100) silicon wafer, and then sputter or evaporate a layer of 0.1-0.5 μm titanium-copper metal seed layer on the oxide layer (as attached Figure 4 -a shown);

[0044] bUse a layer of 25-35μm thick photoresist for photolithography to form a pattern mask for the first electroplating (as attached Figure 4 -b shown);

[0045] c Carry out the first nickel electroplating, make the upper planar cantilever structure, remove the photoresist and metal seed layer; then, use glue spray photoetching to get the oxide layer pattern, in order to carry out the subsequent corrosion (as attached Figure 4 -c shown);

[0046] dUsing the oxide layer as a mask, use 50 °C, 40% potassium hydroxide solution (KOH) to perform anisotropic etching of silicon; and deposit a second time on the upper surface of the entire silicon wafer and the etched deep groove slope and bottom surface 0.1~0.5μm Ti-Cu metal seed layer (if attached F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com