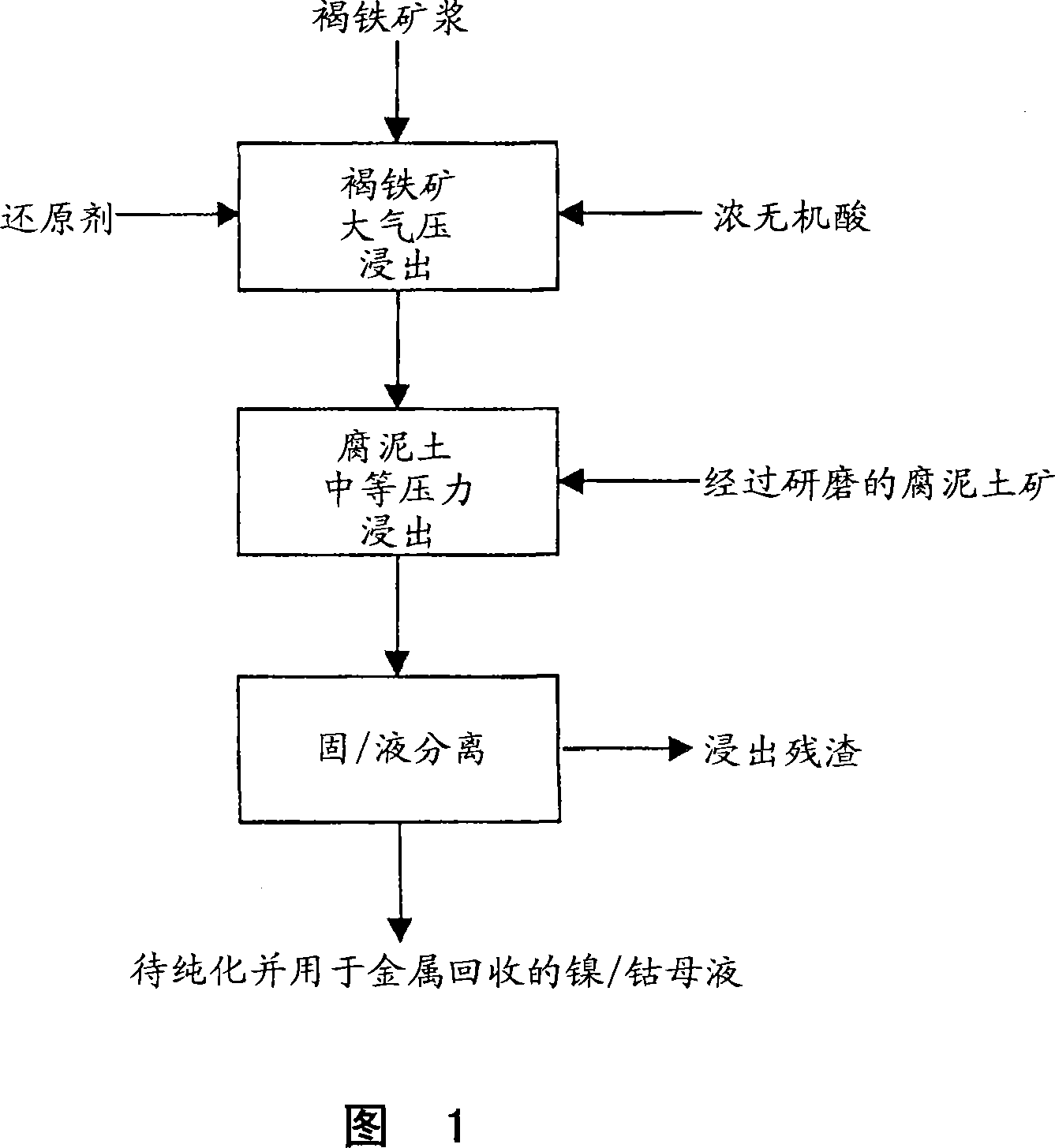

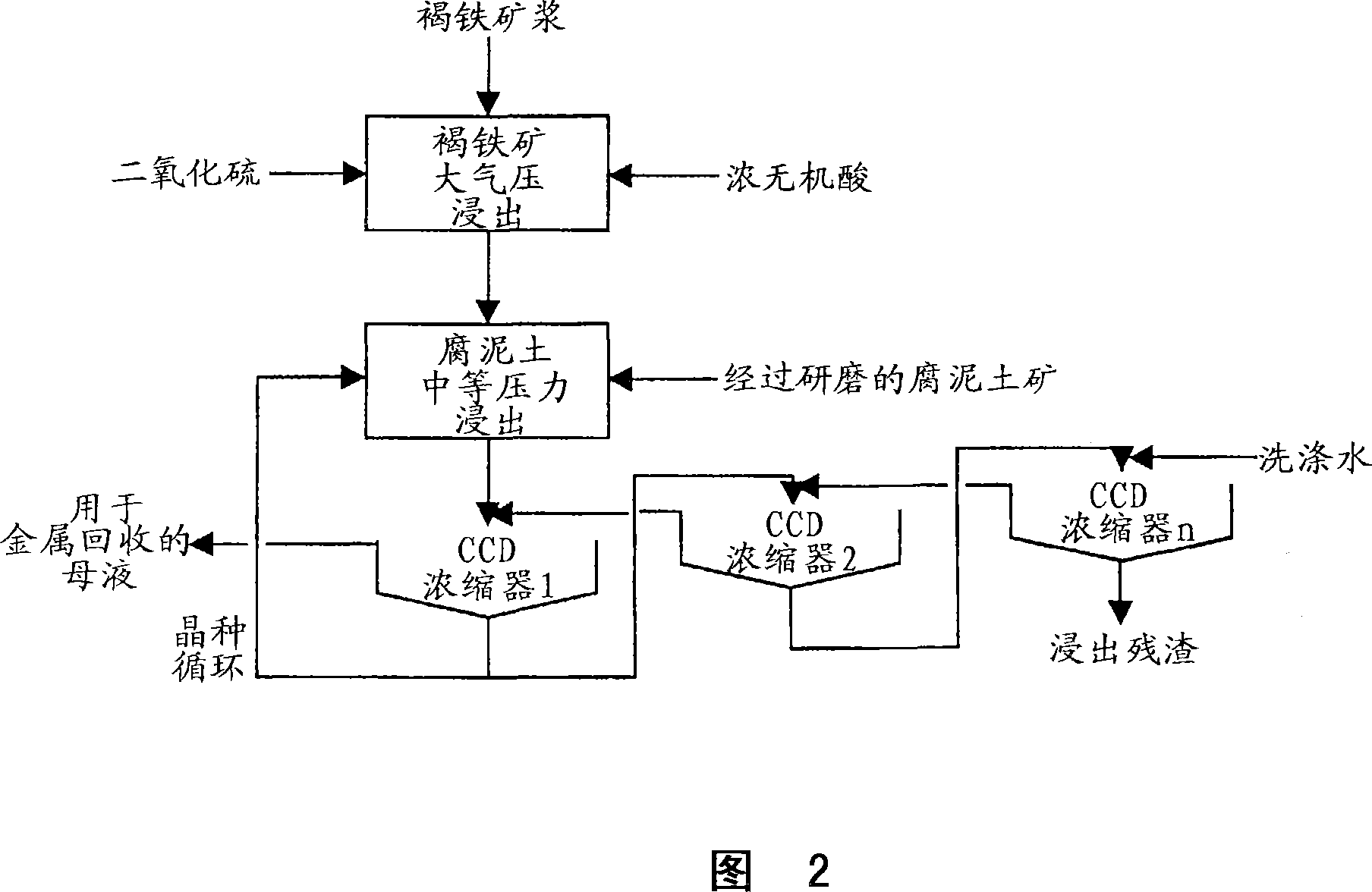

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

An atmospheric pressure, laterite ore technology, applied in the field of hydrometallurgical treatment, can solve the problems of long leaching time and low nickel extraction rate, and achieve the effects of high nickel extraction rate, simple operation and maintenance, and short leaching residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: An acid solution was prepared by adding 287.6 g of 96% sulfuric acid and 48.0 g of 37% HCl (both mineral acids were reagent grade) to 702 mL of water. The acid solution was transferred to a 2 liter cylindrical reaction vessel equipped with a mechanical stirrer, 4 plastic baffles and a tight fitting lid with a water condenser open to atmosphere. The reactor was heated using an external heating mantle. 381.7 g (wet) of the limonite described in Table 1 were added to the acid solution while the mixture was heated and stirred. The temperature was controlled at 94 to 105°C and the limonite ore was leached for 5 hours. Liquid samples were taken from the leach slurry at 1, 2 and 5 hours.

[0059] After 5 hours of leaching, the leach slurry was transferred to a 2 liter titanium autoclave along with 344.8 g (wet) of saprolite ore as described in Table 1. The saprolite ore was first wet ground to about 100 mesh and then filtered to form a filter cake with a moisture...

Embodiment 2

[0069] Example 2: Another experiment was carried out in a manner similar to that described in Example 1, with the following differences. The limonite ore used had the following composition: 1.55% Ni, 48.4% Fe, 0.47% Mg and 37.2% moisture. 398.1g (wet) of this ore was used in the test, while 573.7g of water, 288.2g of 96% H 2 SO 4 , 46.9g 37% HCl and 285.7g MgSO 4 *7H 2 O. No hematite seed material was used in the experiments. MgSO 4 *7H 2 O is dissolved in water and acid is added to the solution. The purpose of adding soluble magnesium to the solution is to simulate the reuse of the magnesium-rich solution left after recovery of nickel and cobalt from the leaching mother liquor. Atmospheric pressure leaching is performed at 96 to 101°C. No samples were taken from the autoclave during the pressure leaching process.

[0070] The analysis results of the liquid samples collected during the atmospheric pressure leaching of limonite are shown in Table 4, and the analysis r...

Embodiment 3

[0078] Example 3: As a comparison, another experiment was carried out simulating the process conditions described in WO 03 / 093517 A1. The limonite atmospheric pressure leaching step is similar to the limonite leaching step described in Example 1. 398.1 g (wet) of limonite identical to that used in Example 2 was added by 719.9 g of water, 288.2 g of 96% H 2 SO 4 and 46.9g of 37% HCl in a solution. Leach at 101-104°C for 4 hours. After 4 hours, 310.6 g of ground saprolite containing 20.0% moisture and 128.6 g of hematite seeds were added to the leaching slurry and leaching was continued at 98-102° C. for an additional 10 hours. Liquid samples were taken periodically during the leaching process. Following the previous examples, the final leach slurry was filtered, the filter cake was reslurried twice with fresh water, and the filtrate, wash solution and washed final residue were analyzed.

[0079] The conditions of this test are therefore basically the same as in Example 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com