Preparation of paclitaxel, and its preparing method

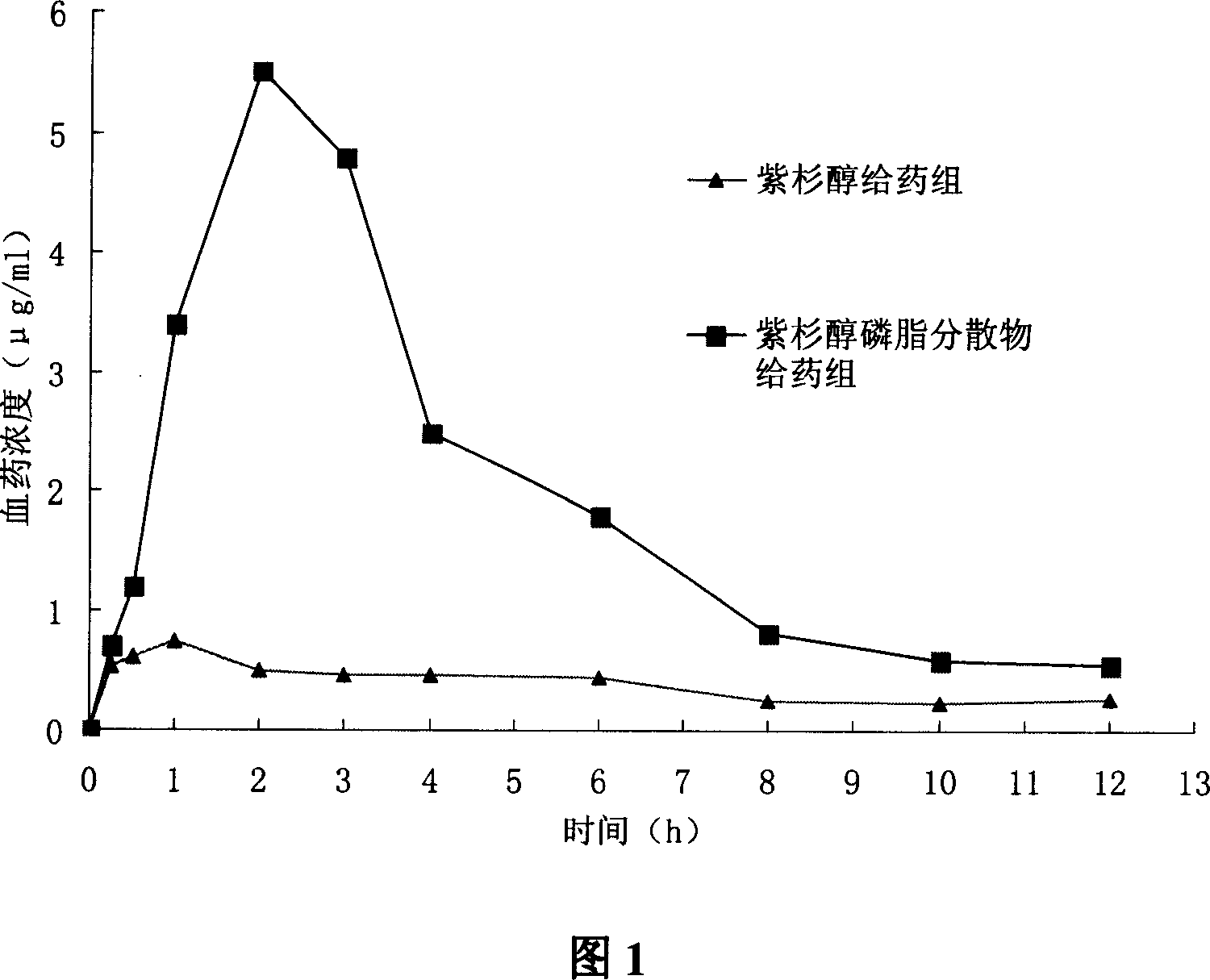

A technology for paclitaxel and paclitaxel phospholipids, applied in the field of medicine, can solve the problems affecting the development and clinical application of paclitaxel oral preparations, poor oral administration bioavailability, low solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 20g of paclitaxel and 250g of oral soybean lecithin, add 1000mL of absolute ethanol and reflux for 45 minutes under heating and stirring; dry it under reduced pressure to 150mL under vacuum pressure -0.09MPa, 60°C water bath heating; then use the concentrated solution The reduced-pressure drying method continues drying at a vacuum pressure of -0.05MPa and 40°C to obtain a paclitaxel phospholipid dispersion; add 500 g of lactose, 10 g of talc, and 15 g of carboxymethyl starch sodium to the prepared paclitaxel phospholipid dispersion , mixed evenly, and prepared into tablets according to the conventional tablet preparation process.

Embodiment 2

[0020] The preparation of embodiment 2 paclitaxel phospholipid dispersion capsules

[0021] Weigh 20g of paclitaxel and 620g of oral egg yolk lecithin, add 1200mL of ethyl acetate and reflux for 1.5 hours under heating and stirring; dry it under reduced pressure to 550mL under vacuum pressure -0.07MPa, 55°C water bath heating; then use the concentrated solution The fluidized bed drying method continued drying at 35°C to obtain the paclitaxel phospholipid dispersion; add 60g of starch and 37g of magnesium stearate to the prepared paclitaxel phospholipid dispersion, mix well, and directly pack it into capsules to prepare into capsules.

Embodiment 3

[0022] The preparation of embodiment 3 paclitaxel phospholipid dispersion pellets

[0023] Weigh 20g of paclitaxel and 900g of soybean lecithin for injection, add 4500mL of chloroform and reflux for 3 hours under heating and stirring; dry it to 650mL under vacuum pressure -0.04MPa, 40°C water bath heating; Press drying method Continue drying under vacuum pressure -0.06MPa and 50°C to obtain the paclitaxel phospholipid dispersion; add 10,000 g of microcrystalline cellulose to the prepared paclitaxel phospholipid dispersion, mix well, and follow the conventional micropellet preparation process Prepare it into pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com