Method for separating highly-pure rare-earth oxide from low-yttrium middle-heavy rare earth mine

A technology of rare earth oxides and rare earth ores, applied in the field of hydrometallurgy, can solve problems such as high energy consumption, poisoning of extractants, and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

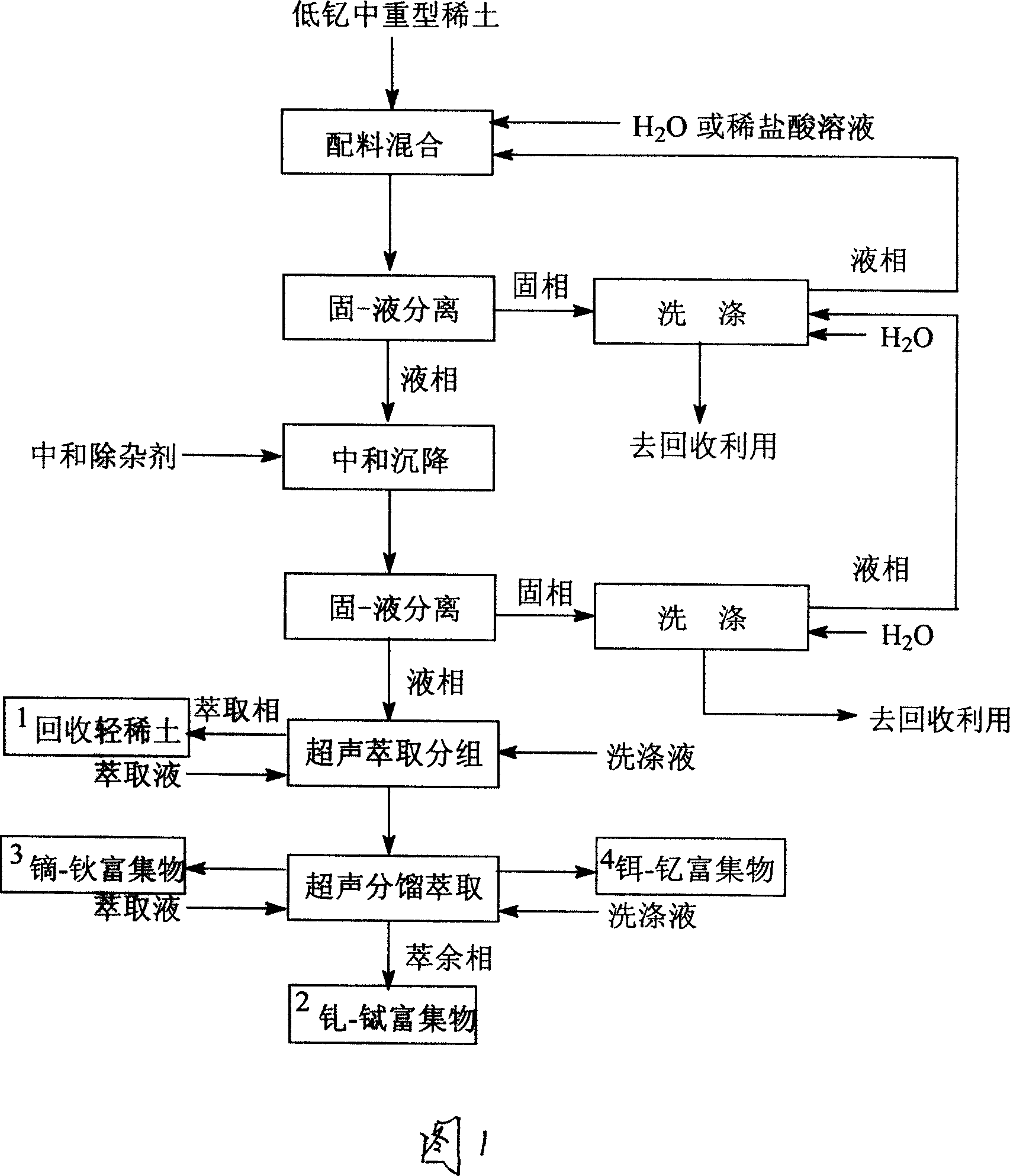

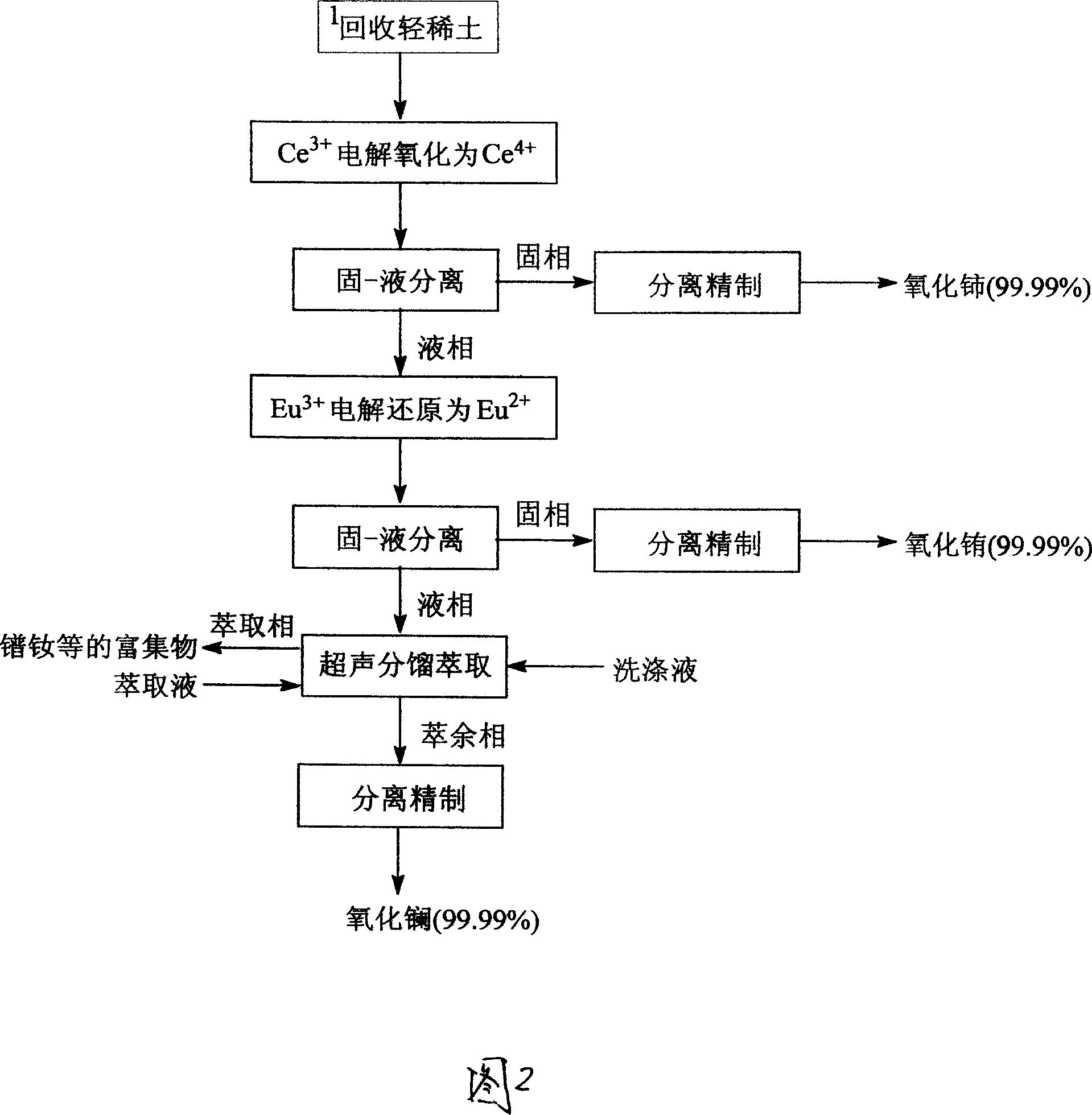

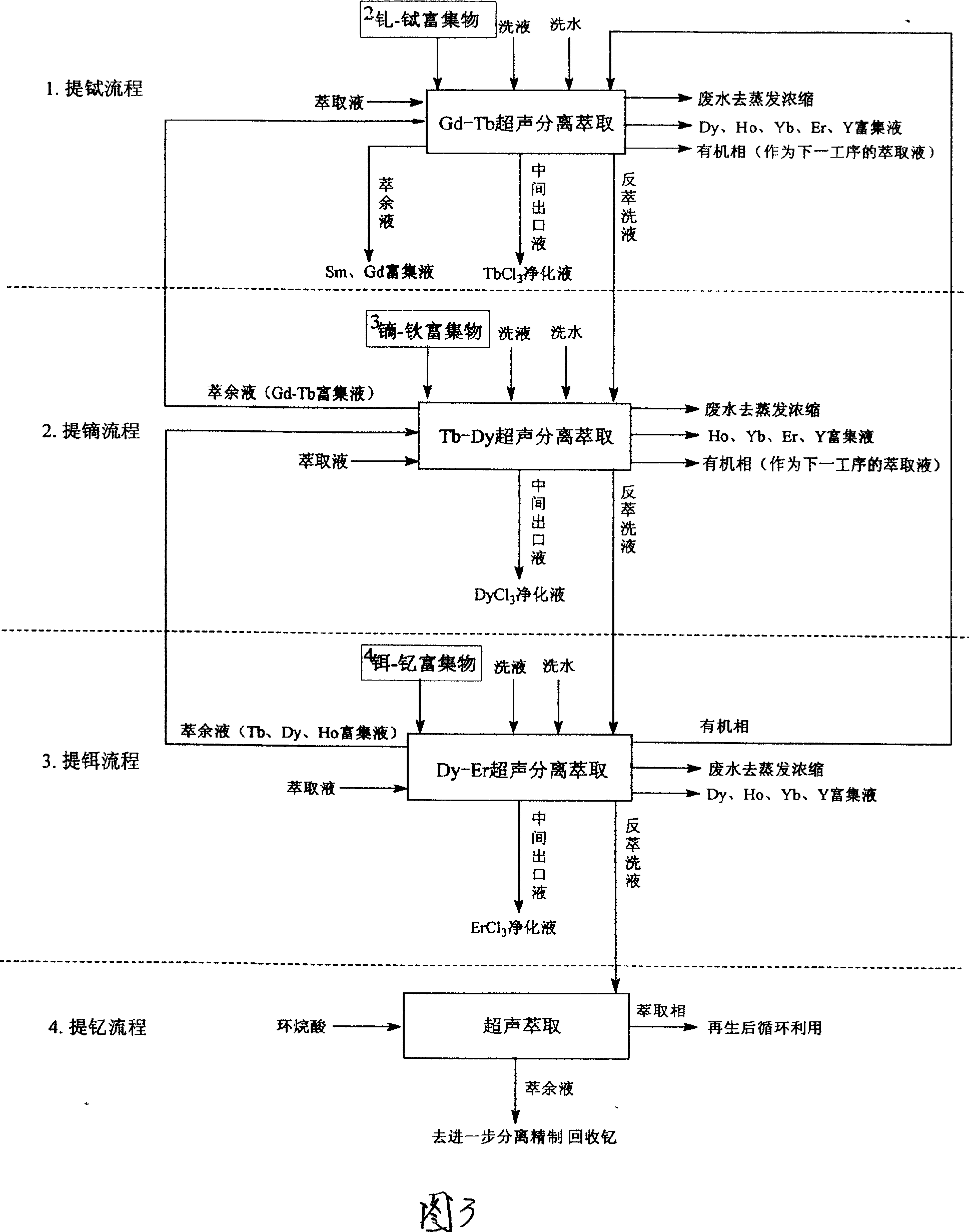

Method used

Image

Examples

Embodiment 1

[0069] Embodiment one (gap operation separation method)

[0070] Main equipment: stirring batching mixing kettle, probe type ultrasonic extraction equipment, flat-plate cationic membrane electrochemical reactor, stirring neutralization precipitation kettle and vacuum filtration solid-liquid separation device, etc.; stirring neutralization precipitation kettle and vacuum filtration solid-liquid separation device, Resistance furnace, pure water and pure acid equipment, analytical testing instruments, etc.

[0071] Main chemical raw materials: medium and heavy rare earth ores with low yttrium (the composition of raw materials is La 2 o 3 、Ce 2 o 3 、Pr 5 o 11 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 4 o 7 、Dy 2 o 3 、Er 2 o 3 , higher mass fraction), hydrochloric acid, liquid ammonia, ammonium carbonate, ammonium bicarbonate, P507 extractant, P204 extractant, naphthenic acid extractant, etc.;

[0072] (1) batching mixing: in 1000ml stirred tank, add 450ml wa...

Embodiment 2

[0093] Embodiment two (continuous operation separation method)

[0094] Main equipment: Stirring batching mixing tank, tank type ultrasonic extraction equipment, fixed bed cationic membrane electrochemical reactor, stirring neutralization precipitation tank and vacuum filtration solid-liquid separation device, various pumps, motors, PVC board (for making extractor), Pond glass reaction tanks, resistance furnaces, pure water and pure acid equipment, analytical testing instruments, etc.

[0095] Main chemical raw materials: medium and heavy rare earth ores with low yttrium (the composition of raw materials is La 2 o 3 、Ce 2 o 3 、Pr 5 o 11 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 4 o 7 、Dy 2 o 3 、Er 2 o 3 higher mass fraction), hydrochloric acid, liquid ammonia, ammonium carbonate, ammonium bicarbonate, P507 extractant, P204 extractant, naphthenic acid extractant, etc.

[0096] (1) batching mixing: in 1000ml stirred tank, add 450ml water, take the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com