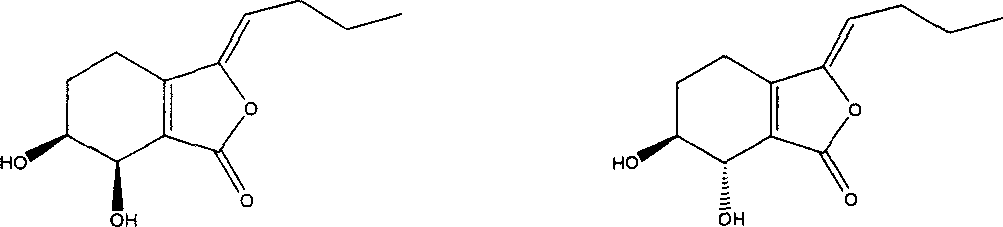

Ligustilide extract and its preparing process and application

A technology of chuanxiongolide and yangchuanxiongolide, which is applied in the field of chuanxiongolide extract and preparation thereof, can solve the problems of low efficiency, high content of unsaturated long-chain fatty acids in volatile oil, and high extraction pressure, and achieves simple technological process, The effect of high product yield and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Remove impurities from the Rhizoma Chuanxiong medicinal material, crush it into coarse powder, take 10 kg of coarse powder, add 100 liters of 75% ethanol, and soak overnight at room temperature. Transfer to an extraction tank, heat to 40°C, extract for 1 hour, filter, add 80 liters of the above-mentioned ethanol to the filter residue, and repeat the above operation. The filtrates from the two extractions were combined, and the ethanol was recovered under reduced pressure at 50° C. to a specific gravity of about 1.0 to obtain an extract with a volume of 3 liters. Transfer the above extract into an extraction tank, add 3 liters of distilled water to the extract, and mix well. Add 16 liters of mixed extraction solvent (ethyl acetate:petroleum ether=5:1), stir under pressure at room temperature for 10 min, let stand for 24 hours, and separate the organic layer. Add 9 liters of mixed extraction solvent (ethyl acetate:petroleum ether=5:1) to the aqueous layer, stir under pres...

Embodiment 2

[0032] Remove impurities from the Rhizoma Chuanxiong medicinal material, crush it into coarse powder, take 10.2 kg of coarse powder, add 100 liters of 80% ethanol, and soak overnight at room temperature. Transfer to an extraction tank, heat to 40°C, extract for 1 hour, filter, add 80 liters of the above-mentioned ethanol to the filter residue, and repeat the above operation. The filtrates from the two extractions were combined, and the ethanol was recovered under reduced pressure at 50° C. to a specific gravity of about 1.0 to obtain an extract with a volume of 3.1 liters. Transfer the above extract into an extraction tank, add 2 liters of distilled water to the extract, and mix well. Add 10 liters of mixed extraction solvent (ethyl acetate:petroleum ether=8:1), stir under pressure at room temperature for 20 min, let stand for 48 hours, and separate the organic layer. Add 8 liters of mixed extraction solvent (ethyl acetate:petroleum ether=1:1) to the aqueous layer, stir under...

Embodiment 3

[0034] Remove impurities from the Rhizoma Chuanxiong medicinal material, crush it into coarse powder, take 9.6 kg of coarse powder, add 100 liters of 70% ethanol, and soak overnight at room temperature. Transfer to an extraction tank, heat to 40°C, extract for 1 hour, filter, add 80 liters of the above-mentioned ethanol to the filter residue, and repeat the above operation. The filtrates from the two extractions were combined, and the ethanol was recovered under reduced pressure at 50° C. to a specific gravity of about 1.0 to obtain an extract with a volume of 2.5 liters. Transfer the above extract into an extraction tank, add 2 liters of distilled water to the extract, and mix well. Add 12 liters of mixed extraction solvent (ethyl acetate:petroleum ether=7:1), stir under pressure at room temperature for 30 min, let stand for 24 hours, and separate the organic layer. Add 8 liters of mixed extraction solvent (ethyl acetate:petroleum ether=7:1) to the aqueous layer, stir under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com