2-Vinyl-terephthalic acid bis-(4-butoxy-phenyl) ester, its polymer, preparing method and application

A technology of vinyl terephthalic acid and polyvinyl terephthalic acid, which is used in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, the synthetic vinyl terephthalate bis[p-butoxyphenol] ester of vinyl terephthalate bis[p-butoxyphenol] ester (BPCS) is shown in formula (I):

[0018] (Formula I)

[0019] Solution A was prepared by dissolving 18g of vinyl terephthalic acid and 49.88g of triphenylphosphine in 168mL of freshly steamed pyridine. Solution B was prepared by dissolving 34.18g of p-butoxyphenol and 50g of hexachloroethane in 332mL of freshly steamed pyridine. Solution B was slowly added dropwise to solution A under ice bath and stirring conditions. After reacting for 36 hours, the reactant was poured into a 1:4 mixed solvent of ethanol / water to obtain a precipitate. After filtration, the filter cake was washed several times with a 1:2 ethanol / water mixed solvent until the filtrate was colorless. After drying, a light yellow solid was obtained. The crude product was separated with a 160-200 mesh silica gel column with dichloromethane as the eluent. The product purified by c...

Embodiment 2

[0020] Embodiment 2, the preparation of polyvinyl terephthalate bis[p-butoxyphenol] ester (PBPCS)

[0021] To a 10 mL polymerization tube with a magnet was added 0.25 mg cuprous bromide (0.0017 mmol) and 0.5 g BPCS (1.02 mmol). Then 10 μL of a chlorobenzene solution containing pentamethyldiethylenetriamine (0.0017 mmol) and α-bromoethylbenzene (0.0017 mmol) was added by syringe. After adding 1.30 g of chlorobenzene, the polymerization solution was frozen, evacuated, and filled with N 2 , repeated four times, and then sealed the tube under vacuum. After the polymerization tube was reacted in an oil bath at 110°C for a period of time, the reaction was terminated and the polymerization tube was broken. After the polymer was diluted with tetrahydrofuran, it was passed through neutral Al 2 o 3 Column, precipitated with methanol. After filtration and drying, the conversion was determined gravimetrically.

[0022] The obtained polymer PBPCS has a relatively low dispersion degre...

Embodiment 3

[0023] Example 3, the application of polyvinyl terephthalate bis[p-butoxyphenol] ester as a processing additive for ultra-high molecular weight polyethylene

[0024] Ultra-high molecular weight polyethylene (UHMWPE) is produced by Beijing Organic Chemical Factory. Its physical properties are: the weight average molecular weight is 3.7 million, and the melting point measured by DSC is 142.8°C.

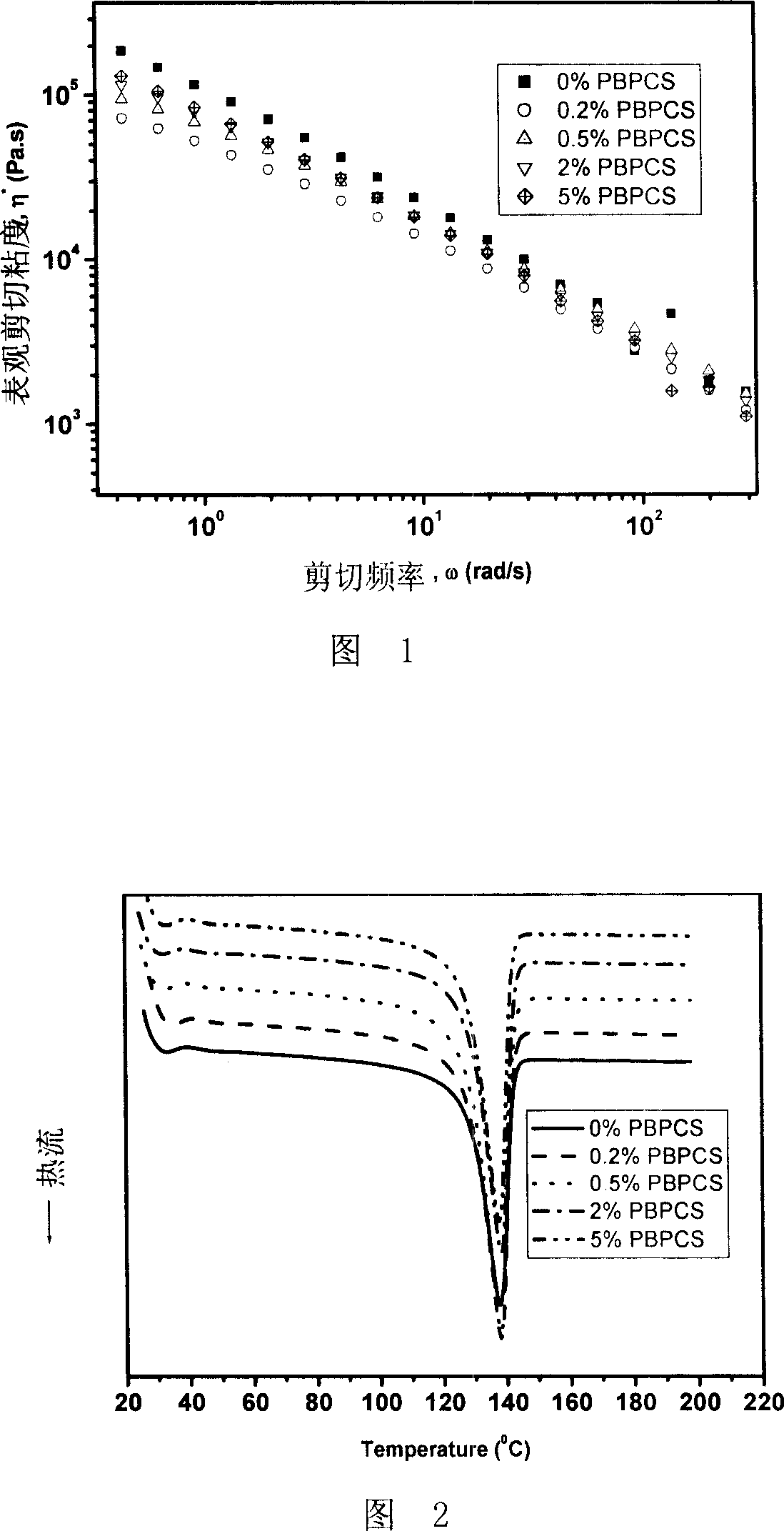

[0025] PBPCS and UHMWPE were dried under vacuum at 80°C for 24 hours, and were co-extruded by DACA Micro Compounder (micro twin-screw extruder) according to the proportion of PBPCS content of 0%, 0.2%, 0.5%, 2%, and 5% (weight). out of molding, the blending temperature is 200°C, and the rotation speed is 50 rpm.

[0026] Characterized by a German Thermo Haake Rheostress 300 dynamic rotational rheometer (at a temperature of 220°C), the apparent shear viscosity of UHMWPE after blending is shown in Figure 1, indicating that the apparent shear viscosity decreases when the PBPCS content is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com