Method of removing arsenic for anode mud with high arsenic and lead content

The technology of lead anode slime and anode slime is applied in the field of precious metal metallurgy, which can solve the problems of large consumption of leachate, high heating temperature and high cost, and achieve the effects of low production cost, low temperature and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

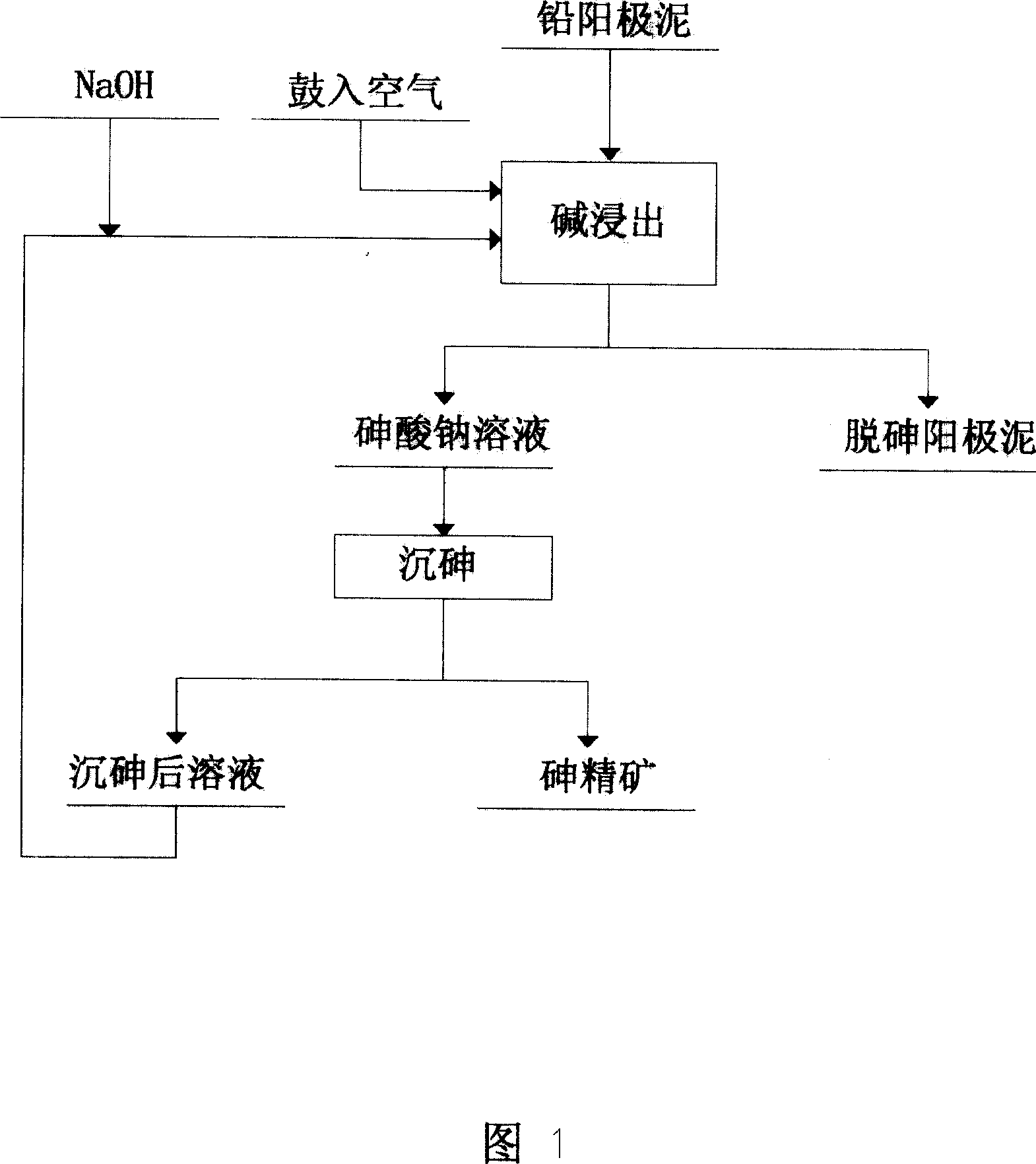

[0026] The production process adopted in this embodiment is shown in Figure 1. High-arsenic lead anode slime is added with lye, and is leached by alkali under the condition of continuously blowing air and heating; the lead anode slime after arsenic removal is used The well-known process comprehensively recovers gold, silver and other valuable metals; the leaching solution contains sodium arsenate, arsenic concentrate is recovered by lime arsenic precipitation, and the solution after arsenic precipitation is supplemented with lye and returned to the alkali leaching process.

[0027] The raw material used in this embodiment is lead anode slime placed for a certain period of time, and its chemical composition is shown in Table 1.

[0028] Table 1

[0029] Element

Ag

Cu

Pb

As

Sb

Bi

Content / %

5.87

1.74

24.69

7.14

36.55

17.62

[0030] A. Slightly pulverize the above-mentioned anode slime...

Embodiment 2

[0035] The production process adopted in this embodiment is the same as in Example 1.

[0036] The raw material used in this embodiment is anode slime that has been placed for a certain period of time, and its chemical composition is shown in Table 2.

[0037] Table 2

[0038] Element

Ag

Cu

Pb

As

Sb

Bi

Content / %

6.85

1.32

20.85

8.55

35.17

19.31

[0039] A. Slightly pulverize the anode slime with a particle size of -90 mesh;

[0040] B. The anode slime was stirred and leached with 2.2mol / L NaOH for 8 hours under the condition of solid / liquid ratio (kg / L)=1:4, temperature 69°C, and continuous air blowing;

[0041] C, alkaline immersion solution is cooled to room temperature, adjusts pH=14, adopts lime to deposit arsenic, reclaims arsenic concentrate;

[0042] D. Add NaOH to the leaching solution after arsenic removal until its concentration in the solution is 2.2mol / L, and circulat...

Embodiment 3

[0044] The production process adopted in this embodiment is the same as in Example 1.

[0045] The raw material used in this embodiment is anode slime placed for a certain period of time, and its chemical composition is shown in Table 3.

[0046] Table 31

[0047] Element

Ag

Cu

Pb

As

Sb

Bi

Content / %

3.95

3.81

27.61

5.13

34.25

16.82

[0048] A. Slightly pulverize the anode slime with a particle size of -85 mesh;

[0049] B. Anode slime was stirred and leached with 2.1mol / L NaOH for 6 hours under the condition of solid / liquid ratio (kg / L)=1:6, temperature 50°C, and continuous air blowing;

[0050] C, alkaline immersion solution is cooled to room temperature, adjusts pH=14, adopts lime to deposit arsenic, reclaims arsenic concentrate;

[0051] D. Add NaOH to the leaching solution after arsenic removal until its concentration in the solution is 2.1mol / L, and circulate back to leachin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com