Dielectric ceramic composition and the production method

A ceramic composition and manufacturing method technology, applied in capacitor manufacturing, fixed capacitor dielectrics, ceramics, etc., can solve the problems of high temperature load life deterioration and other problems, achieve high temperature accelerated life, high reliability, maintain Q value and insulation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] First, in order to finally obtain the composition formula (Ca 0.70 Sr 0.30 )O-(Zr 0.97 Ti 0.03 )O 2 Represented dielectric oxide, blending each oxide and carbonate (CaCO 3 , SrCO 3 , ZrO 2 、TiO 2 ), to obtain the main component raw materials.

[0101] Then, 3 mol of Li-W-B-Si-O glass as a sintering aid prepared in advance was added to 100 mol of the obtained main component raw material, wet mixed in a ball mill, and dried to obtain a dielectric ceramic composition raw material. Furthermore, Li-W-B-Si-O glass as a sintering aid was produced as follows. That is, first, in order to obtain a predetermined composition, the oxides of each component, that is, Li 2 O. WO 3 , B 2 o 3 and SiO 2 . Then, it was subjected to wet mixing and pulverization in a ball mill for 16 hours, then evaporated and dried, and the dried powder was sintered at 1000° C. in air for 2 hours. Thereafter, fine pulverization is performed to obtain glass component powder having an average ...

Embodiment 2

[0131] In addition to using Li-V-B-Si-O glass (Li 2 O: 11 parts by weight; V 2 o 5 : 6 parts by weight; B 2 o 3 : 23 parts by weight and SiO 2 : 60 parts by weight) except as a sintering aid, a capacitor sample was produced in the same manner as in Example 1, and evaluated in the same manner as in Example 1. In addition, in Example 2, when producing each sample, the heating rate during sintering was each rate shown in Table 2, and a total of 5 types of samples were produced. The results are shown in Table 2.

[0132] Table 2

[0133] sample

serial number

second component

Liter during sintering

Temperature speed [℃ /

Hour]

Content of V element

Q value

IR

[Ω]

HALT

[Hour]

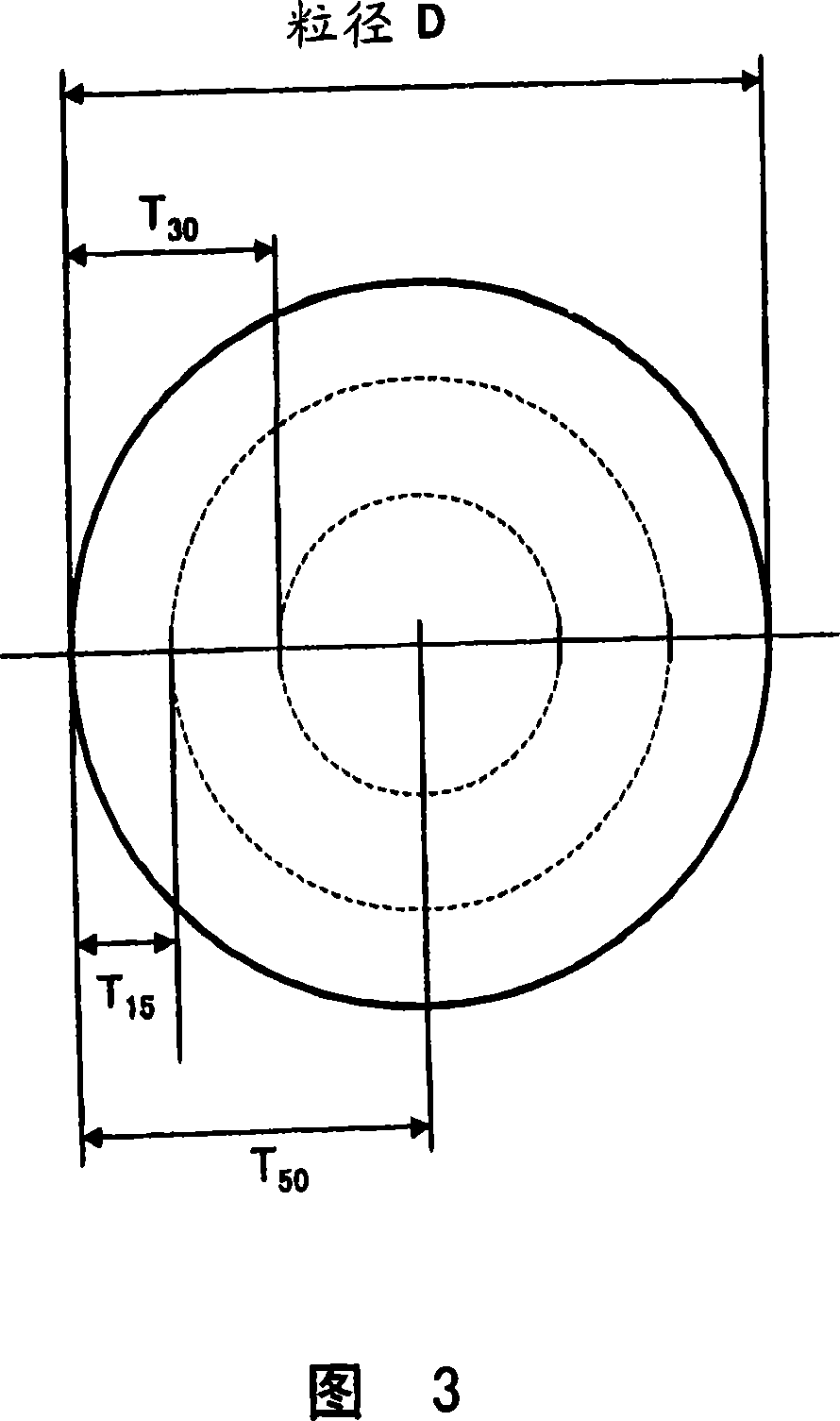

T 15

[%]

T 30

[%]

T 60

[%]

11

comparative example

V 2 o 5

100

83.7

82.3

80.9

5,023 ...

Embodiment 3

[0137] In addition to using Li-Mo-B-Si-O glass (Li 2 O: 11 parts by weight; MoO 3 : 6 parts by weight; B 2 o 3 : 23 parts by weight and SiO 2: 60 parts by weight) except as a sintering aid, a capacitor sample was produced in the same manner as in Example 1, and evaluated in the same manner as in Example 1. In addition, in Example 3, when producing each sample, the temperature increase rate during sintering was each rate shown in Table 3, and a total of 5 types of samples were produced. The results are shown in Table 3.

[0138] table 3

[0139]

sample

serial number

second component

Liter during sintering

Temperature speed [℃ /

Hour]

Mo element content

Q value

IR

[Ω]

HALT

[Hour]

T 15

[%]

T 30

[%]

T 50

[%]

16

comparative example

MoO 3

100

84.3

83.4

82.1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com