High-dispersed titanium pigment and its production

A technology of titanium dioxide and dispersibility, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of large amount of neutralizing agent, low water dispersibility, high production cost, etc., and achieve system stability, Improve the hiding power and mechanical strength of the coating film, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Preparation of titanium dioxide of the present invention

[0029] The pigment-grade metatitanic acid slurry is beaten into a solution of 200g / L (calculated as titanium dioxide), and 10 liters are taken, and the mass percentage calculated as potassium oxide is added as metatitanic acid (calculated as TiO2). 2 0.35% of potassium sulfate, calculated as phosphorus pentoxide, the mass percent is metatitanic acid (calculated as TiO 2 Total) 0.2% phosphoric acid, mass percent is metatitanic acid (as TiO 2 meter) 0.35% antimony trioxide, stirring. Add ammonia water to adjust the pH value to 8, adding mass percent is metatitanic acid (using TiO 2 Count) 0.4% of oπ-10.

[0030] Thoroughly stir the obtained liquid, filter it, take the filter cake and calcinate it in a resistance furnace at 930°C, and grind it with a three-head grinder for 1 hour to obtain anatase titanium dioxide A.

Embodiment 2

[0031] Embodiment 2 Preparation of titanium dioxide of the present invention

[0032] The pigment-grade metatitanic acid slurry is beaten into a solution with a concentration of 340g / L (calculated as titanium dioxide), and 10 liters are taken, and the mass percentage is added as metatitanic acid (calculated as TiO2). 2 meter) 0.5% potassium sulfate (calculated as potassium oxide), the mass percentage is metatitanic acid (calculated as TiO 2 0.3% phosphoric acid (calculated as phosphorus pentoxide), the mass percentage is metatitanic acid (calculated as TiO 2 meter) 0.35% antimony trioxide, stirring. Add mass percentage and be the urea of titanium dioxide 5%, add mass percentage again and be metatitanic acid (as TiO 2 Count) 0.3% of oπ-10.

[0033] Thoroughly stir the above-mentioned obtained product, filter, take the filter cake and calcinate it in a resistance furnace at 900°C, and grind it with a three-head grinder for 2 hours to obtain anatase titanium dioxide B.

Embodiment 3

[0034] Embodiment 3 Preparation of titanium dioxide of the present invention

[0035] The pigment-grade metatitanic acid slurry is beaten into a solution of 340g / L (in terms of titanium dioxide), and 10 liters are taken, and the mass percentage calculated in terms of potassium oxide is added as metatitanic acid (in terms of TiO2). 2 0.45% potassium sulfate, the mass percent of metatitanic acid (based on TiO 2 Total) 0.28% phosphoric acid, mass percent is metatitanic acid (as TiO 2 meter) 0.45% antimony trioxide, stirring. Add mass percentage and be the ammonium carbonate of titanium dioxide 3%, add mass percentage again and be metatitanic acid (as TiO 2 Count) 0.2% of oπ-10.

[0036] Thoroughly stir the above-mentioned obtained product, filter it, take the filter cake and calcinate it in a resistance furnace at 950°C, and grind it with a three-head grinder for 2 hours to obtain anatase titanium dioxide C.

PUM

| Property | Measurement | Unit |

|---|---|---|

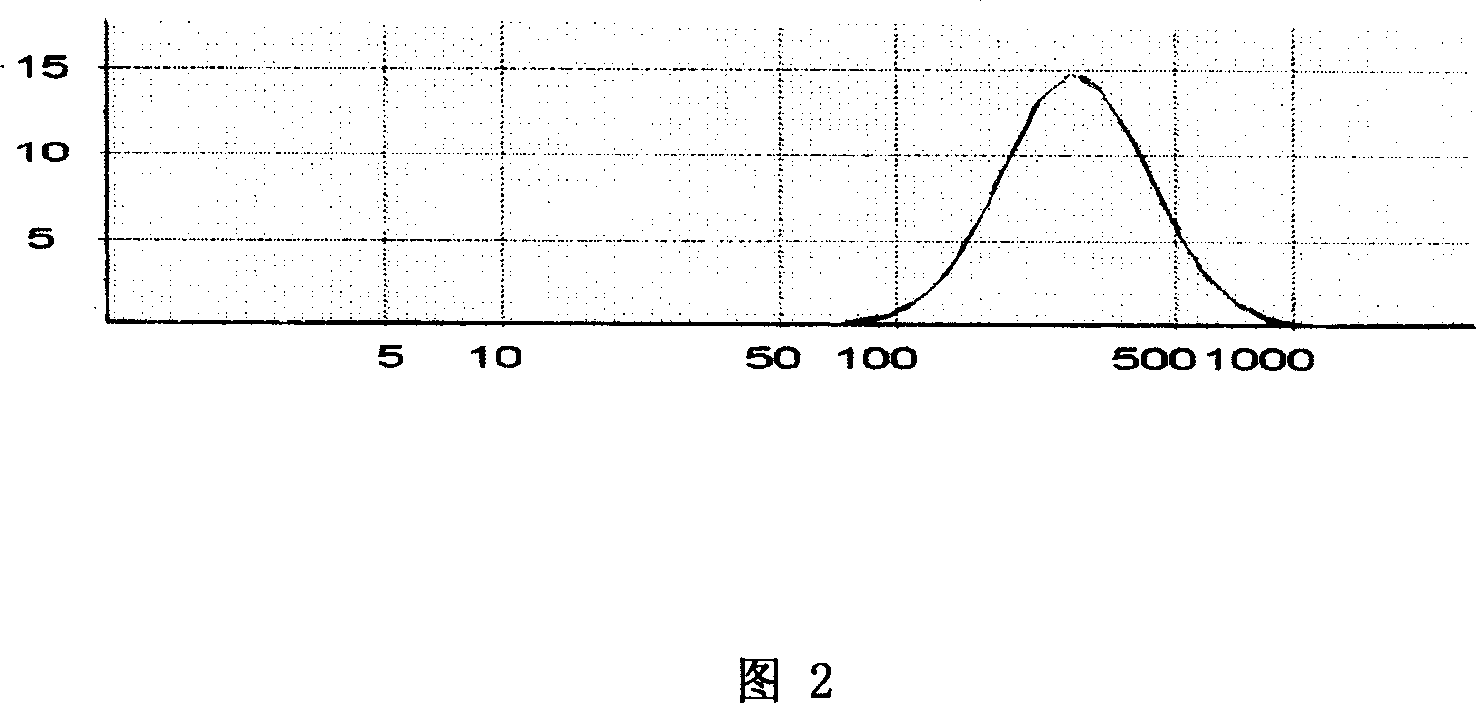

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com