Fluororesin-coated member, mold comprising the member for polyester container molding, and method of regenerating the mold

A technology for forming molds and fluororesin, which is applied to other household appliances, coatings, household appliances, etc., can solve the problem of taking a long time, achieve the effects of easy regeneration, improve wear resistance, and prevent adhesion and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] 1. Fabrication of Biaxial Stretch Blow Molding Mold

[0111] (1) Mold making

[0112] The aluminum 7075-T651 material (hardness Hv300g: 190) used as the base of the mold is cut and processed to make a mold (two divided master molds), which can be biaxially stretched and blow-molded to produce a bottle diameter: 65mm, removing the mouth Height: 185mm, content: 500ml Polyester bottle with a cylindrical cross section.

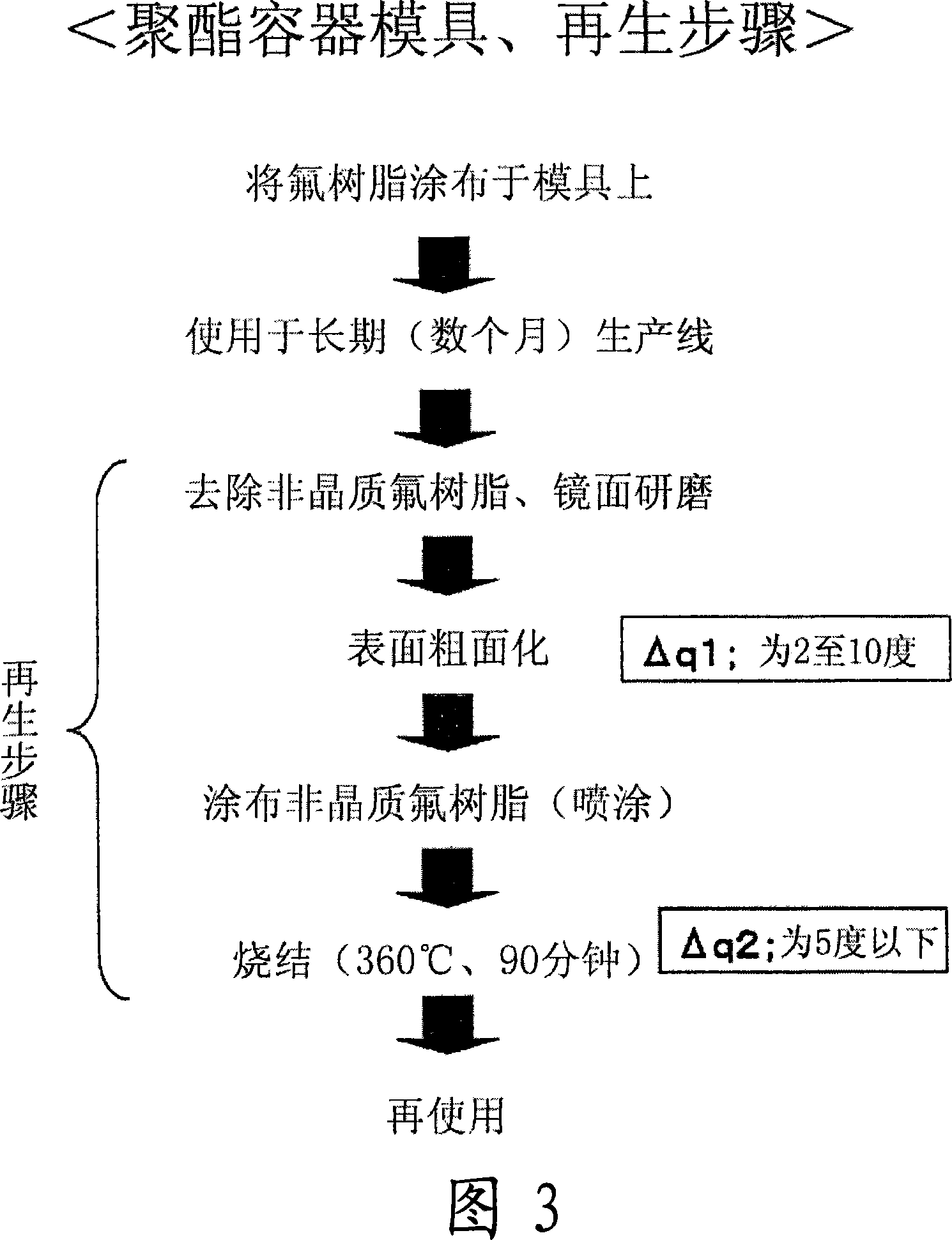

[0113] Afterwards, the surface of the mold is ground with a grinding wheel for precision processing, and then, the silicon carbide raw material powder with a particle size distribution of several μm to tens of μm is treated by blowing shot peening within a few seconds under a pressure of 0.1Mpa. To carry out rough surface processing until the mean square gradient Δq1 of surface roughness reaches 10 degrees.

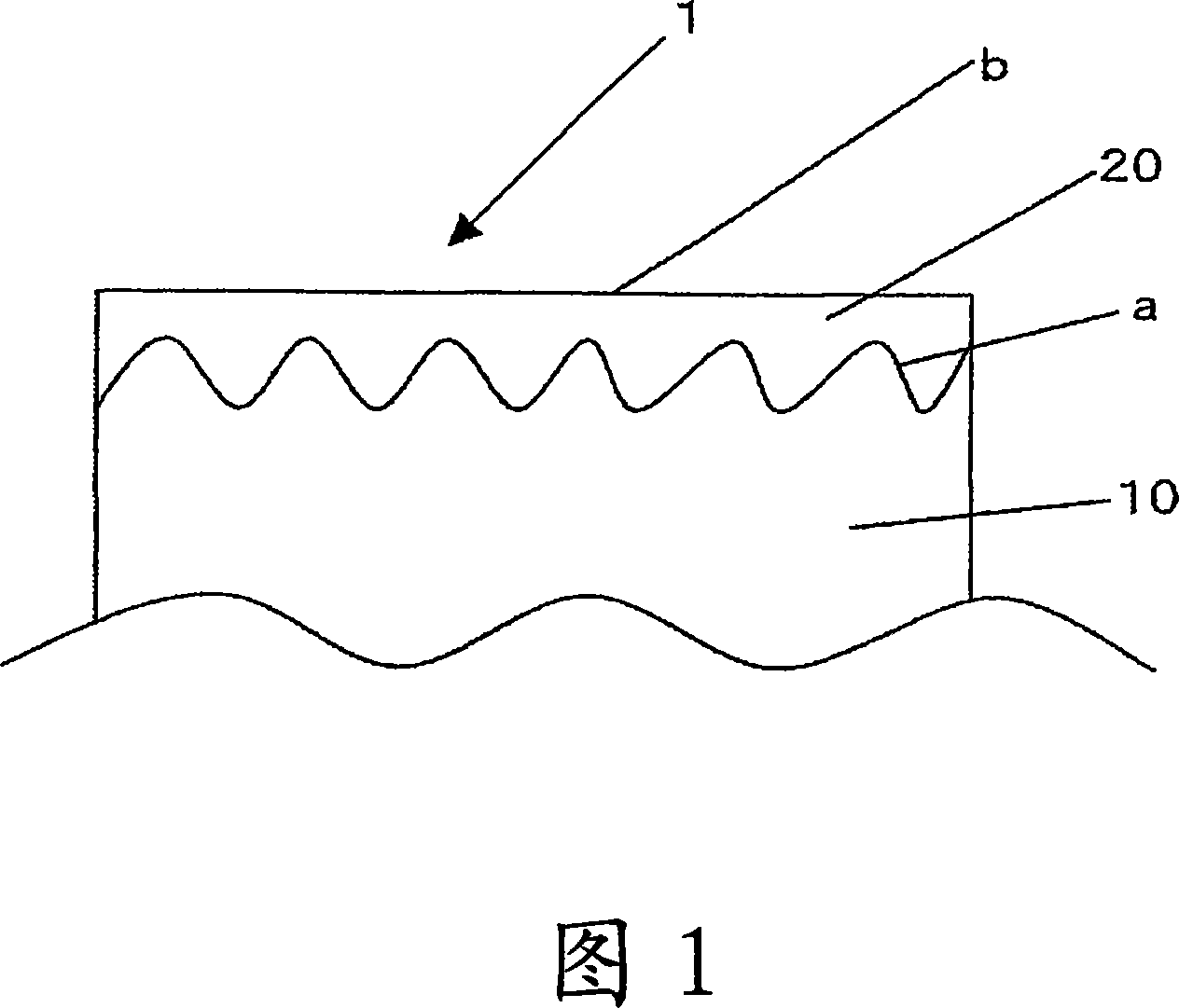

[0114] (2) Formation of fluororesin layer

[0115] The above-mentioned mold was cleaned with alcohol, and an amorphous fluororesin [AF2400] (glass ...

Embodiment 2

[0120] Use the quenched and tempered material of 13 chromium (13Cr) manganese-containing stainless steel (Hitachi Metals (Co., Ltd.) HPM38, hardness Hv300g: 550) as the base of the mold, and perform rough surface processing until the mean square gradient Δq1 of the surface roughness is 6. degree, then in the formation of the mold base fluororesin layer, dissolve the solution of the fluororesin to make the concentration 0.6% by weight / volume, then spray it on the surface of the mold, and sinter the fluororesin in an electric furnace at 340°C for 30 minutes. Heating and melting, except for the formation of a coating amount of 5g / m 2 1. Except for the fluororesin layer whose mean square gradient Δq2 of surface roughness was 3 degrees, the same fluororesin coating mold and polyester container as in Example 1 were produced, and then similarly evaluated. Also, there was no change in the hardness of the base material after sintering.

Embodiment 3

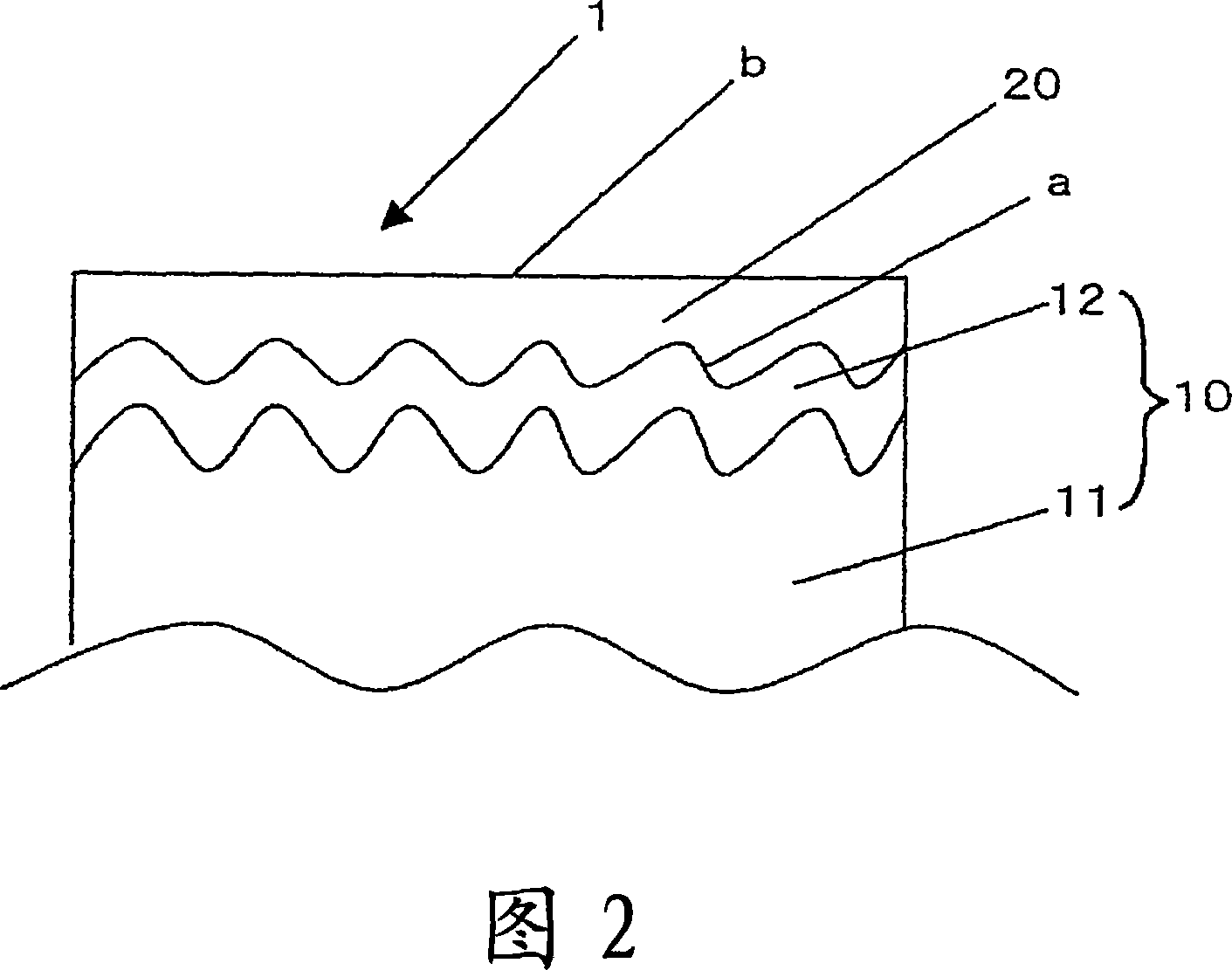

[0122] In Example 1, the surface of the aluminum 7075-T651 material of the mold base is ground, and a hard layer with an average thickness of 20 μm formed by the electroless nickel-phosphorus alloy plating layer is set on the surface (hardness Hv25g: 600 ) as the base of the mould, the above-mentioned hard layer is subjected to precision processing with a grinding wheel, and then, except that the average average gradient Δq1 of the surface roughness reaches 2 degrees by shot blasting, it is made into the same as that of the embodiment 1 same mold.

[0123] In addition, in the formation of the fluororesin layer on the surface of the mold, the solution of the fluororesin is dissolved to make the concentration 0.6% by weight / volume, sprayed on the surface of the mold, and fired in an electric furnace at 360°C for one and a half hours to carry out the fluorine resin solution. Heated and melted, except for the formation of a coating amount of 0.5g / m 2 Except for the fluororesin la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com