Colibacillus-lactic acid bacteria shuttle plasmid capable of expressing and excreting beta-galactosidase and its construction method and application

A technology of galactosidase and Escherichia coli, which is applied in the direction of botany equipment and methods, biochemical equipment and methods, applications, etc., can solve unfavorable industrial preparation of enzyme products, β-galactosidase does not have secretion, β -Galactosidase can not be secreted and other problems, to achieve the effect of wide application value and direct application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

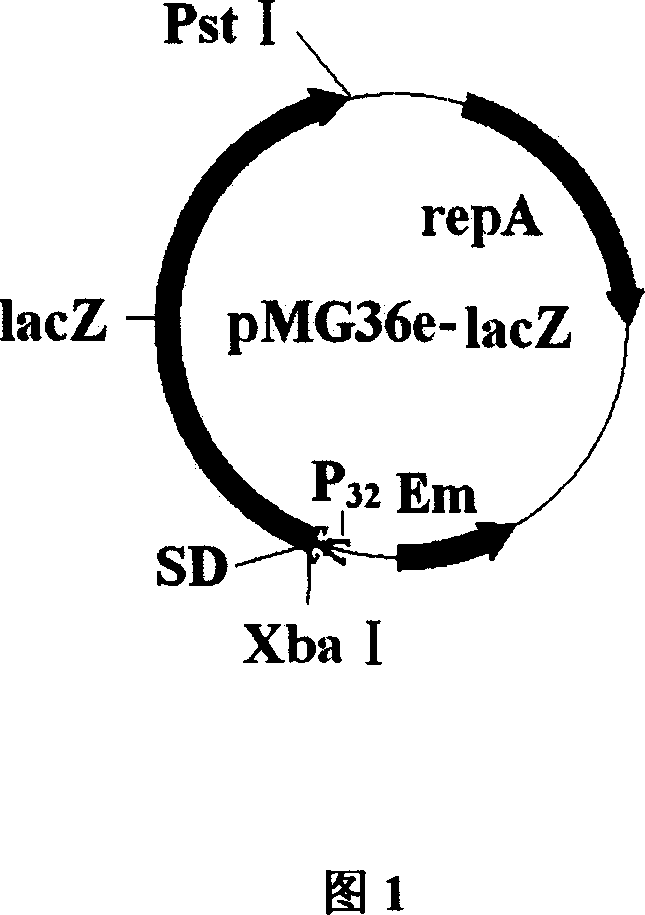

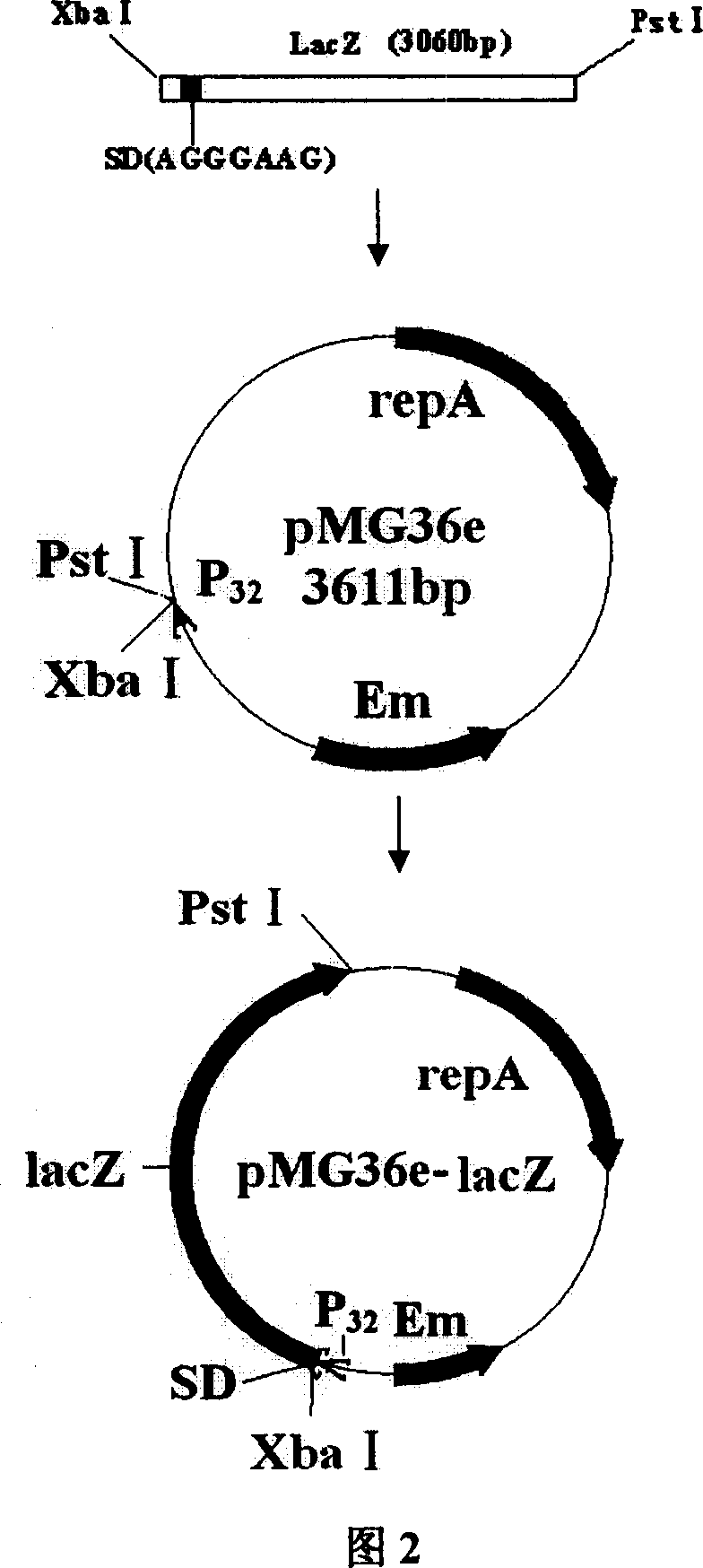

[0034] Example 1: Construction of Escherichia coli-lactic acid bacteria shuttle plasmid capable of expressing and secreting β-galactosidase

[0035] In this example and subsequent examples, the Escherichia coli-lactic acid bacteria shuttle plasmid capable of expressing and secreting β-galactosidase was named pMG36e-lacZ. The steps of its construction method are as follows:

[0036] (1) Amplification of Lactobacillus delbrueckii subsp. bulgaricus β-galactosidase gene fragment (SEQ ID NO.3)

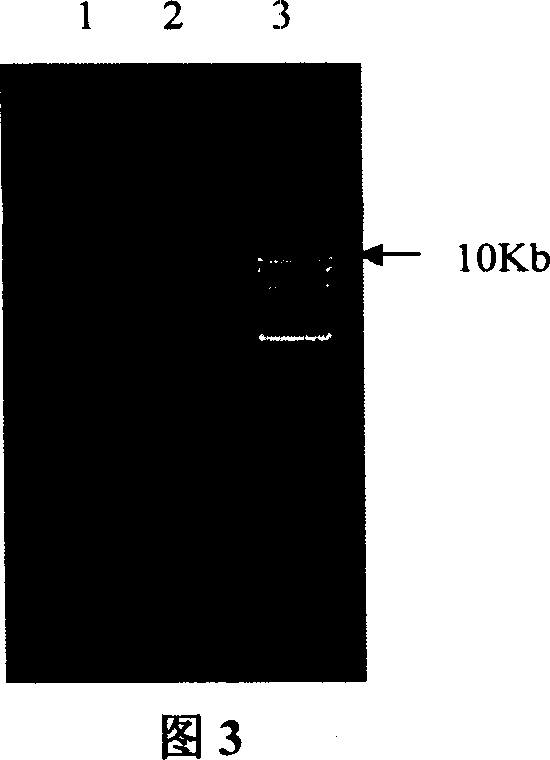

[0037] Take Lactobacillus delbrueckii subsp. bulgaricus out of the refrigerator at -20°C, melt in a water bath at 37°C, streak the MRS plate, culture at 37°C for 48 hours, pick colonies and transfer to 5ml MRS broth, culture at 37°C for 24 hours, use a small amount of The bacterial genomic DNA extraction kit extracts genomic DNA as a template, and the extracted product is checked by 0.8% agarose gel electrophoresis, and there is an obvious band at >10kb in the positive result (see Figure 3...

Embodiment 2

[0066] Example 2: Electrotransformation of Lactococcus lactis with the recombinant plasmid pMG36e-lacZ

[0067] (1) Preparation of Lactococcus lactis cells for electroporation

[0068] Lactococcus lactis strains were taken out from the -20°C refrigerator, melted in a 37°C water bath, and cultured on a streaked MRS plate at 30°C for 48 hours. Pick colonies from the plate and inoculate 5ml of MRS broth, incubate at 30°C for 12-16h, pipette 5ml of bacterial liquid into 100ml of MRS broth, and incubate at 30°C until A 600 It is 0.5-0.8 (about 4h). 1 h before stopping the culture, ampicillin was added to make the final concentration 20 μg / ml. After stopping the culture, draw the bacterial solution into a clean, sterile, pre-cooled 50ml polypropylene centrifuge tube, and place it in an ice bath for 10 minutes. Centrifuge at 4000r / min for 7min at 4°C, discard the supernatant, invert the tube, and absorb the residual liquid with a sterile filter paper strip. Add 20ml of ice-cold g...

Embodiment 3

[0080] Example 3: Expression of recombinant plasmid pMG36e-lacZ in Escherichia coli DH5α

[0081] The positive bacteria E.coli DH5α / pMG36e-lacZ were obtained after the recombinant plasmid pMG36e-lacZ was transformed into Escherichia coli DH5α, and the β-galactosidase activity of the bacteria was determined to study the expression of the recombinant plasmid pMG36e-lacZ in Escherichia coli.

[0082] E. coli DH5α / pMG36e-lacZ streaked LB-Ery-X-gal plate, cultured at 37°C for 48 hours, picked blue colonies on the plate and inoculated 15ml of LB-Ery broth, cultured with shaking at 220r / min at 37°C for 24 hours; E. coli DH5α streaked LB plate, cultured at 37°C for 24 hours, picked a single colony on the plate to inoculate 15ml of LB broth, and cultured at 37°C with shaking at 220r / min for 24 hours. Take 10ml of the bacterial solution in a 50ml centrifuge tube (10ml bacterial solution / centrifuge tube), centrifuge at 15000r / min for 3min at 4°C, discard the supernatant, wash the bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com