Controlling method for air single-preheating partitional directional selecting valve heat accumulating burner

A control method and reversing valve technology, which are applied to combustion methods, control combustion, lighting and heating equipment, etc., can solve the problems affecting the life of refractory materials and metal components, difficult maintenance, and large equipment, saving development and debugging cycles, The effect of high application promotion value and shortened development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

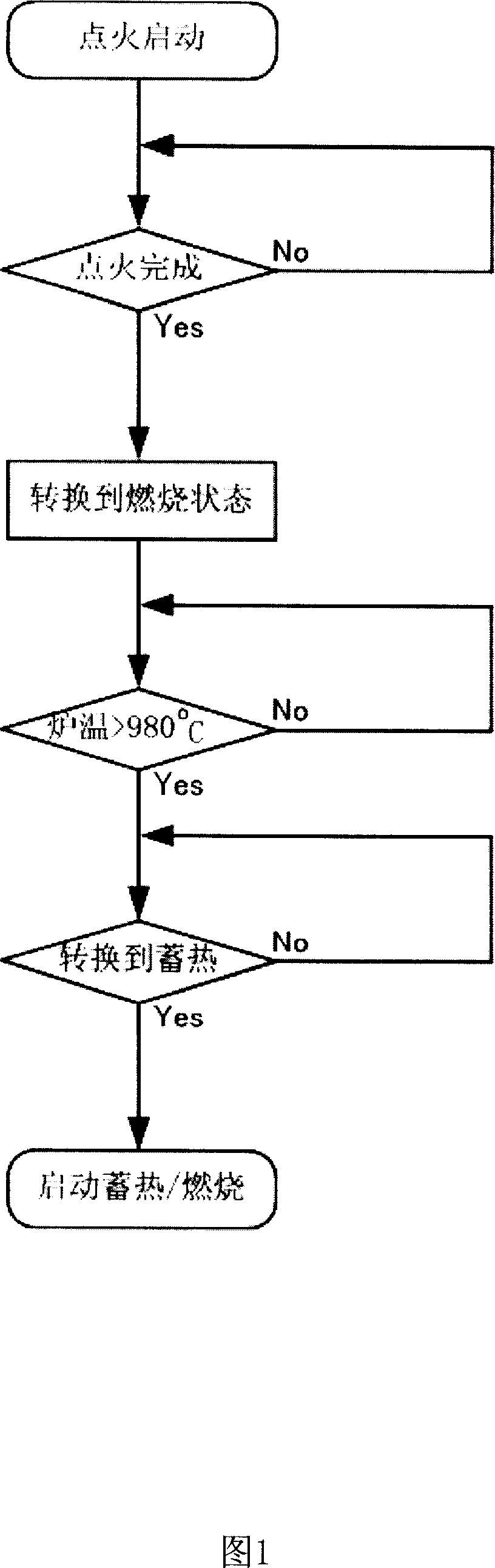

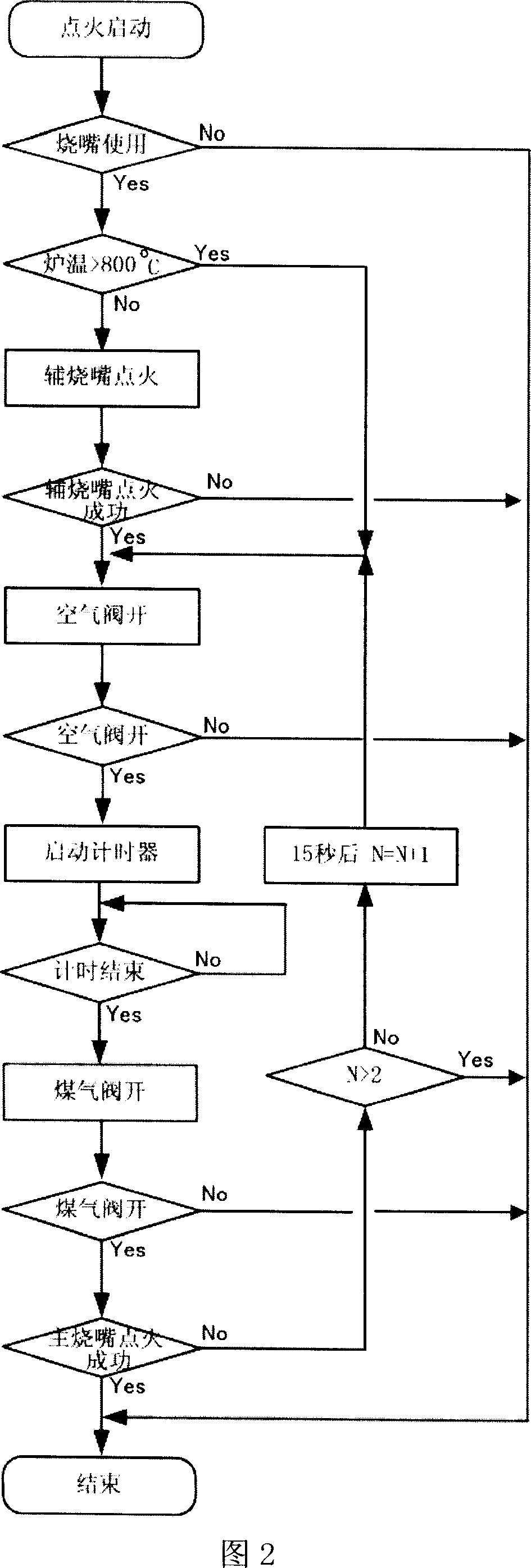

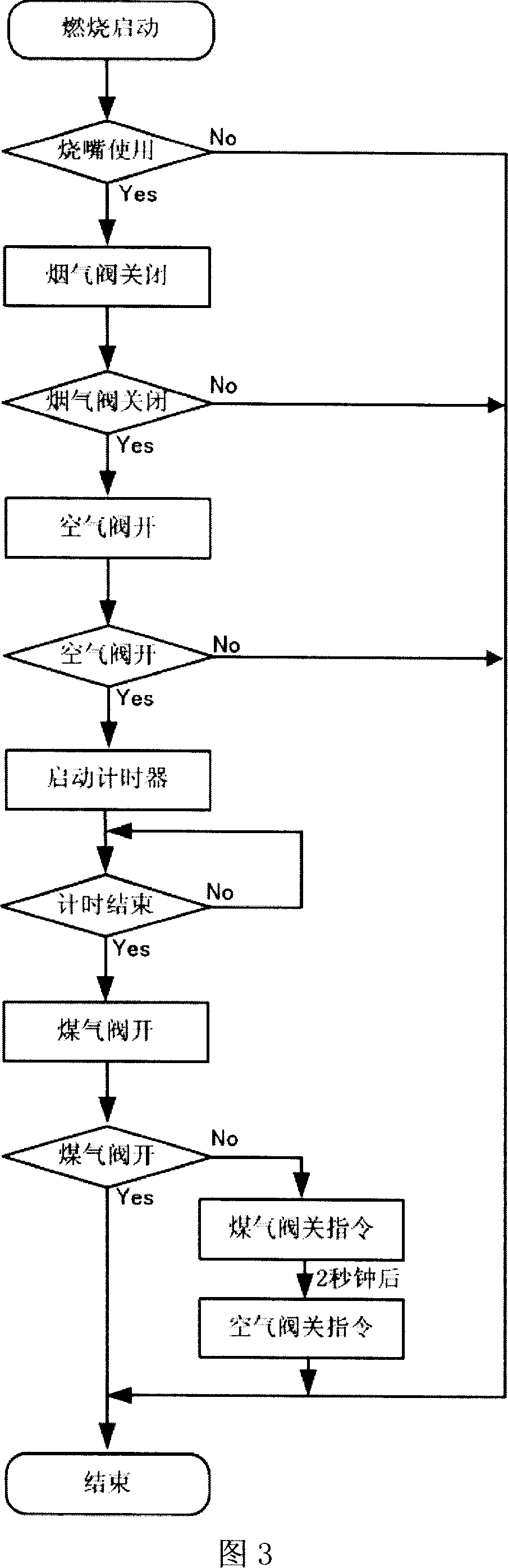

Embodiment Construction

[0020] The burner type regenerative burner organically combines the regenerator and the burner, and the regenerator in the regenerator adopts a composite regenerative structure of ceramic pellets and ceramic honeycomb. The working principle of the regenerative burner is: the normal temperature air coming out of the blower enters the regenerative burner through the reversing valve and is heated, and the normal temperature air is heated to close to the furnace temperature in a very short time. The heated high-temperature air enters the furnace and burns with fuel; at the same time, the high-temperature hot flue gas after combustion in the furnace stores heat energy in the regenerative burner when it passes through the regenerative burner on the opposite side; the low-temperature flue gas Exhausted through the chimney via the reversing valve.

[0021] Regenerative burners usually have three combustion modes: conventional combustion, cross-reversal and centralized reversing.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com