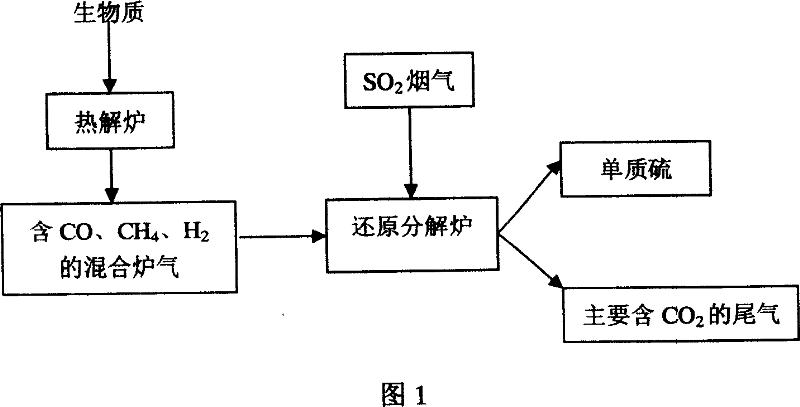

Method for deacidizing low sulfur dioxide concentration by using gas produced by biomass pyrolysis

A sulfur dioxide, low-concentration technology, applied in the field of flue gas desulfurization, can solve problems such as energy waste, environmental pollution, and the safety of waste residue utilization to be investigated, and achieve the effect of reducing emissions and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: TiO 2 The carrier is immersed in 15% ferric nitrate solution for 4 hours, dried at 110-120°C until the water content is below 2wt%, and then calcined at 500-600°C for 4.5-5 hours until ferric nitrate is decomposed to form iron oxide, and finally mixed with gas ( SO 2 :N 2 =1:9) after pre-curing for 2 hours. The prepared catalyst is loaded into the reduction and decomposition furnace to make a catalytic reduction fixed bed; the raw material of the desulfurizer is stalk, and the stalk with a water content of 10% after drying is crushed to a particle size below 20mm, and the crushed stalk enters The pyrolysis reaction is carried out in the pyrolysis furnace, the temperature is controlled at 450 ° C ~ 550 ° C, and the reaction is carried out for 1 hour. During the reaction, the CO and CH in the furnace gas are continuously detected online by a flue gas analyzer. 4 、H 2 Concentration, the generation mainly contains 30% CO, 30% CH 4 , 20%H 2 The mixed pyro...

Embodiment 2

[0027] Example 2: the gamma-Al 2 o 3 The carrier was immersed in a 5% lanthanum nitrate solution for 6 hours, dried at 110-120°C to a moisture content of 0.5wt%, and then calcined at 600°C for 4 hours until the lanthanum nitrate was decomposed to form lanthanum oxide, and finally mixed gas (SO 2 :N 2 =1:9) after pre-curing for 1.5h. The prepared catalyst is loaded into the reduction and decomposition furnace; the raw material of the desulfurizer is wood chips, and the wood chips with a water content of 15% after drying are crushed to a particle size below 3mm, and the crushed wood chips enter the pyrolysis furnace, and the temperature is controlled at 500℃~600℃, the biomass is pyrolyzed in the pyrolysis furnace for 1 hour, and the CO and CH in the furnace gas are continuously detected online by the flue gas analyzer during the reaction process 4 、H 2 concentration. Generate mainly 20% CO, 40% CH 4 , 10%H 2 Mixed furnace gas; pyrolysis reaction containing 20% CO, 40% C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com