Lead-free compatible high frequency copper clad laminate and its preparing method

A copper clad laminate, high-frequency technology, applied in printed circuit manufacturing, printed circuit components, electrical components, etc., can solve problems such as unfriendly human body and environment, and the generation of harmful gases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

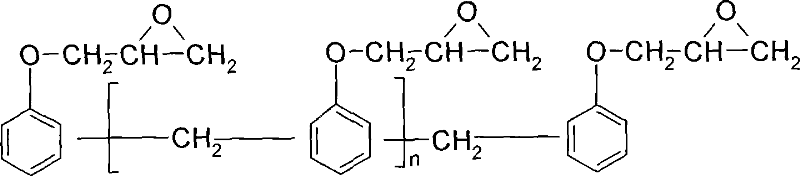

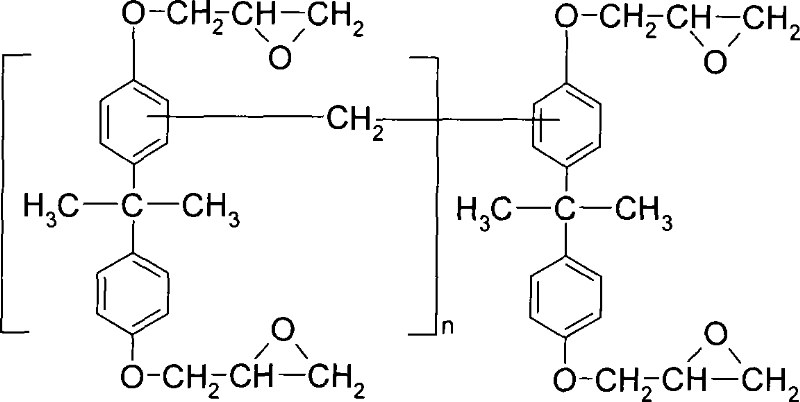

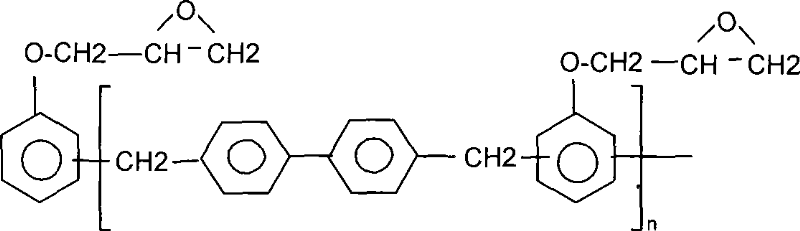

Method used

Image

Examples

Embodiment 1

[0066] Take 35 parts of multifunctional epoxy resin, 23 parts of phosphorus-containing phenolic resin, 21 parts of PTFE, 20 parts of silicon micropowder and 1 part of imidazole accelerator, add an appropriate amount of methyl ethyl ketone as a solvent, and prepare it with a solid content of 65% under sufficient stirring. resin solution.

[0067]Use 2116NE glass fiber cloth to impregnate the above resin solution, and bake at 170°C for 5 minutes to make a bonding sheet. The resin content of the adhesive sheet was 53%, and the resin fluidity was 20%.

[0068] Take 8 bonding sheets, stack them neatly, cover both sides with 35μm electrolytic copper foil, and then sandwich them between two mirror stainless steel plates, place them in a vacuum press, at 195±3°C, 30Kg / cm 2 Under the condition of hot pressing for 90 minutes, a double-sided copper clad laminate is made. The test results of copper clad laminates are shown in Table 1.

Embodiment 2

[0070] Take 37 parts of multifunctional epoxy resin, 25 parts of phosphorus-containing phenolic resin, 20 parts of PTFE, 17 parts of silicon micropowder and 1 part of imidazole accelerator, add an appropriate amount of methyl ethyl ketone as a solvent, and prepare a solid content of 65% under sufficient stirring resin solution.

[0071] Use 2116NE glass fiber cloth to impregnate the above resin solution, and bake at 170°C for 5 minutes to make a bonding sheet. The resin content of the adhesive sheet was 53%, and the resin fluidity was 21%.

[0072] Take 8 bonding sheets, stack them neatly, cover both sides with 35μm electrolytic copper foil, and then sandwich them between two mirror stainless steel plates, place them in a vacuum press, at 195±3°C, 30Kg / cm 2 Under the condition of hot pressing for 90 minutes, a double-sided copper clad laminate is made. The test results of copper clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com