New technique for producing cement by using carbide mud residue ingredient of shaft kiln

A technology of slag batching and new technology, which is applied in the new technology field of producing cement by using calcium carbide slag batching in shaft kilns. It is easy to meet environmental protection standards, save energy consumption for drying and grinding, and save limestone resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

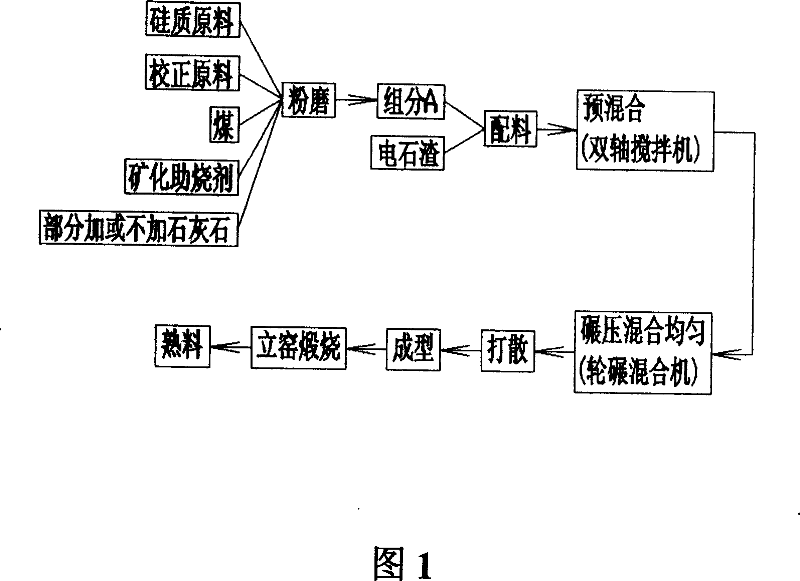

Method used

Image

Examples

Embodiment

[0030] The vertical kiln trial production line of a factory in Zhuzhou used carbide slag discharged from the production of polyvinyl chloride of Zhuzhou Chemical Group to replace limestone. The calcium carbide slag has a moisture content of 35-38% and an average dry basis CaO content of 67.70%. Raw materials used in trial production are fly ash, silica sand, sulfuric acid mud, zinc slag, anthracite and carbide slag. The dry raw meal powder is made of fly ash, silica sand, sulfuric acid mud, zinc slag and anthracite, and is ground by a Φ1.83×7m raw meal mill with a classifier, with a fineness of 80um and a 9.8% sieve. The dry raw meal powder and calcium carbide slag are pre-mixed in the twin-shaft mixer after metering and batching, and then unloaded into the planetary wheel mill mixer for rolling and mixing. The bar material is sent to the vertical kiln by the belt, and the original material ball enters the kiln belt and is transported into the kiln for calcination.

[0031] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com