Preparation method of zirconium tetrachloride

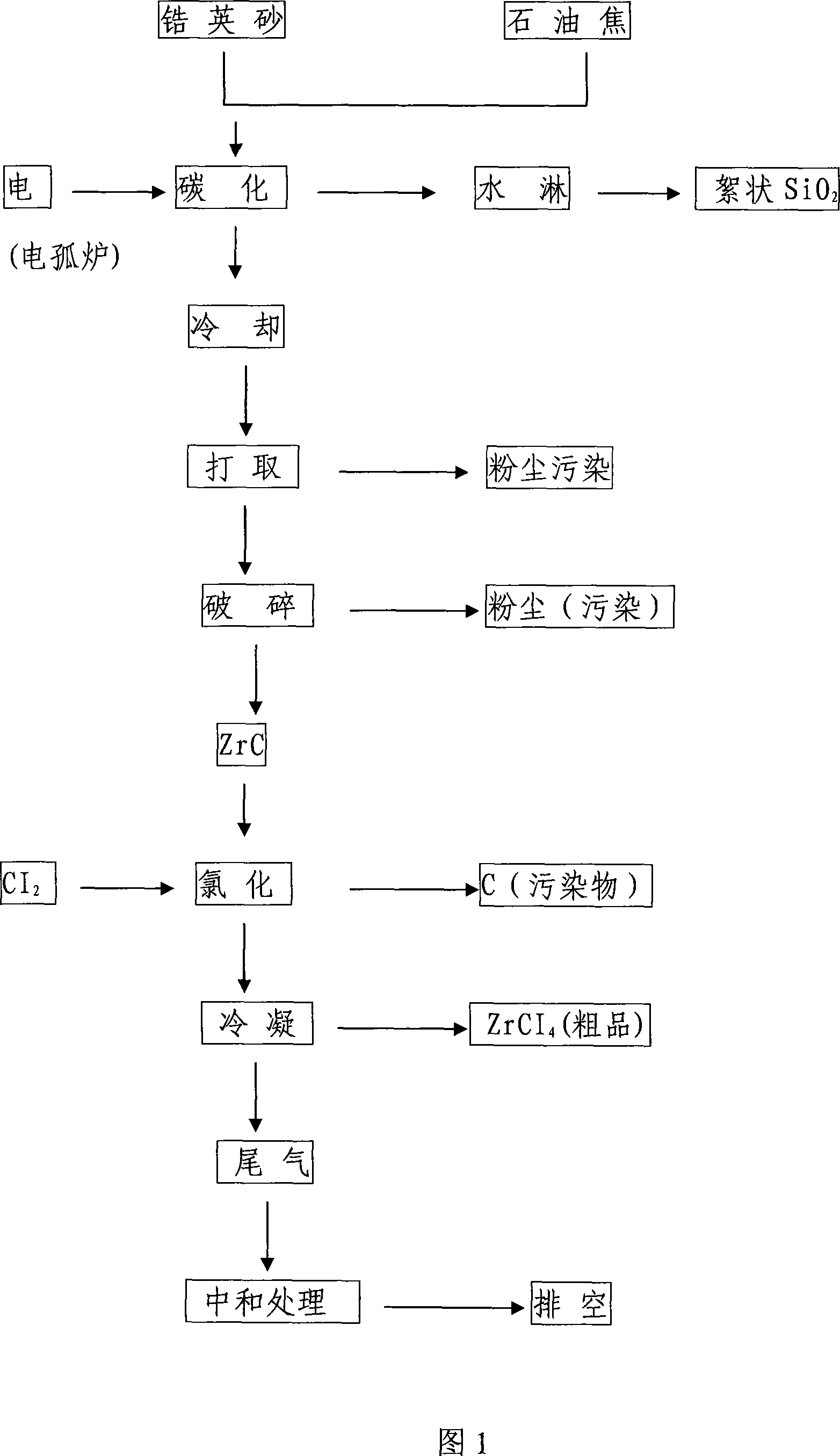

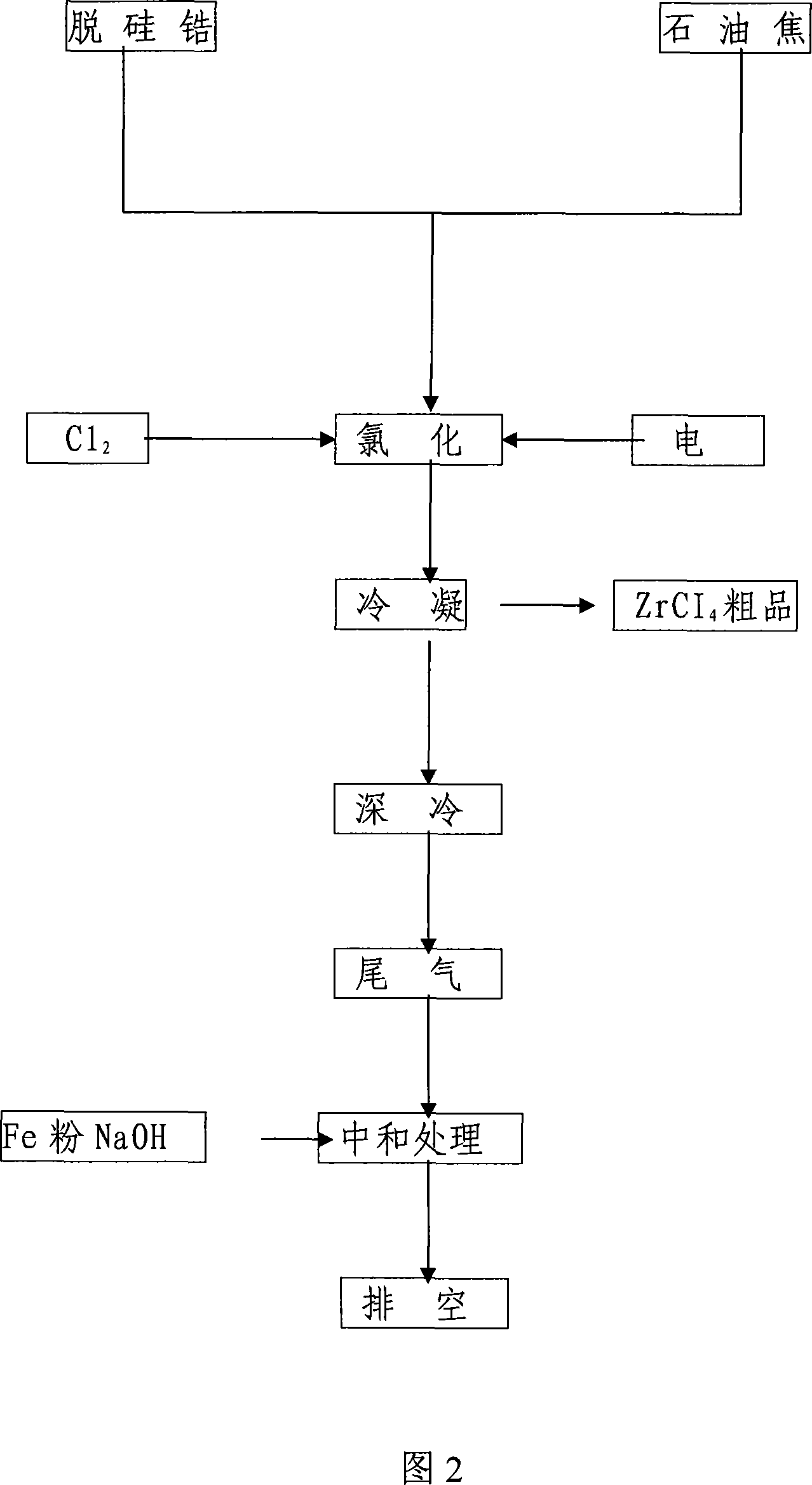

A technology of zirconium tetrachloride and zirconium oxide, which is applied in the direction of zirconium halide, etc., can solve the problems of shortening the process flow, impact on product yield and purity, and large difference in product quality, so as to achieve short process flow, shorten production process flow, and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for producing zirconium tetrachloride with boiling furnace, first zircon sand (ZrSiO 4 ) is desiliconized in an electric arc furnace in advance, the weight percentage of desiliconized zirconia is greater than 92%, and SiO in zirconia 2 The content should be less than 0.5% by weight. Desiliconized zirconium is crushed into 160-325 mesh fine powder, mixed with 100-200 mesh petroleum coke to increase uniformity, and the weight ratio is 100:18; desiliconized zirconia and petroleum coke fine powder are pre-heated at a temperature of 80-200°C Dehydration treatment for 1-2 hours; when the furnace temperature rises to 900±5°C, add the dehydrated material into the fluidized furnace at a feeding rate of 100-150kg / hour, and feed chlorine at a rate of 0.67M 3 / hour, and react at a temperature of 900~1100±5°C for 20~21 hours. The reacted material is cooled to 200±10°C for 8-10 hours, and then continued to cool to 20±5°C for 3-5 hours. The finally discharged hydrochlori...

Embodiment 2

[0032] The raw materials after dehydration treatment are ready for use. Raise the boiling furnace temperature from 0 to 900°C for 2 to 3 hours. When the furnace temperature reaches 900°C, add the dehydrated material at a feeding rate of 150kg / hour, and feed chlorine gas at the same time. The rate of chlorine gas is 0.85M 3 / hour, react at 900-1100±5°C for 20-21 hours, and the zirconium tetrachloride produced is condensed by a condenser to obtain the product. Other conditions are with embodiment 1.

Embodiment 3

[0034] Dehydrate the desiliconized zirconia and petroleum coke powder at 150-200°C for 1.5 hours; raise the boiling furnace temperature to 0-900°C for 2-3 hours, add the dehydrated materials when the furnace temperature rises to 900°C, and the feeding speed It is 120kg / hour, feed chlorine gas at the same time, the flow rate is 0.8M 3 / hour, reacted at 900~1100±5°C for 20~21 hours, and other conditions were the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com