Method for producing propene ethylene by carbon-contained alkene

A technology of propylene ethylene and carbon olefins, applied in ethylene production, hydrocarbon cracking to hydrocarbon production, organic chemistry, etc., can solve problems such as low olefin yield, and achieve the effect of improving conversion rate and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

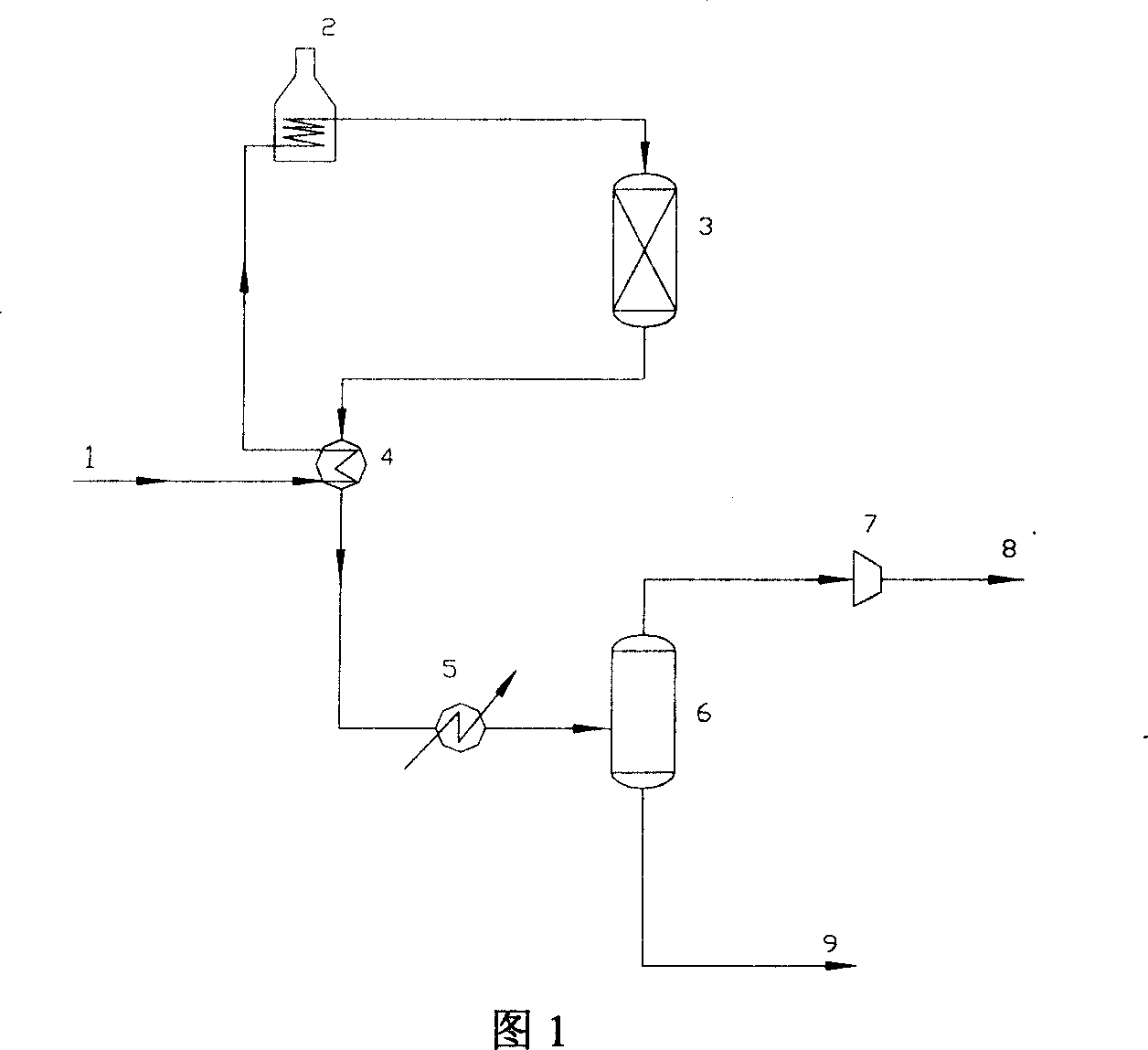

[0031] As shown in Figure 1, the carbon-containing olefin mixture composition (weight %) is: isobutene: 45%, isobutane: 55%. Adopt the technological process of the present invention, catalyst is the ZSM-5 molecular sieve that silicon-aluminum molar ratio is 200, and reaction weight hourly space velocity is 10 hours -1 , the reaction temperature is 450°C, the reaction pressure is 15KPa (absolute pressure), and the temperature behind the partial condenser 5 is 25°C. The pilot plant proves that the product in the following ratio will be obtained (relative to the olefin content of the raw material):

[0032] C 2 ~C 3 : 68.3%

[0033] Fuel gas: 0.08%

[0034] C 4 Above fraction: 31.6%

Embodiment 2

[0036] As shown in Figure 1, the composition of the carbon-containing olefin mixture is the same as in Example 1. Adopt the technological process of the present invention, catalyst is the ZSM-5 molecular sieve that silicon-aluminum molar ratio is 200, and reaction weight hourly space velocity is 80 hours -1 , temperature of reaction is 500 DEG C, and reaction pressure is 30KPa (absolute pressure), and the temperature behind partial condenser 5 is 45 DEG C, will obtain the product (weight %) of following ratio:

[0037] C 2 ~C 3 : 65.5%

[0038] Fuel gas: 0.07%

[0039] C 4 Above fraction: 34.4%

Embodiment 3

[0041] As shown in Figure 1, the composition of the carbon-containing olefin mixture is the same as in Example 1. Adopt the technological process of the present invention, catalyst is the ZSM-5 molecular sieve that silicon-aluminum molar ratio is 200, and reaction weight hourly space velocity is 30 hours -1 , temperature of reaction is 550 ℃, and reaction pressure is 50KPa (absolute pressure), and the temperature behind partial condenser 5 is 55 ℃, will obtain the product (weight %) of following ratio:

[0042] C 2 ~C 3 : 69.5%

[0043] Fuel gas: 0.1%

[0044] C 4Above fraction: 30.4%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com