Disinfectant for improving hydrogen peroxide bactericidal activity

A technology of hydrogen peroxide and bactericidal activity, which is applied in the direction of disinfectants, biocides, animal repellants, etc., can solve the problems of high concentration, large dosage, and slow sterilization speed of hydrogen peroxide, etc. Strong, broad-spectrum bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

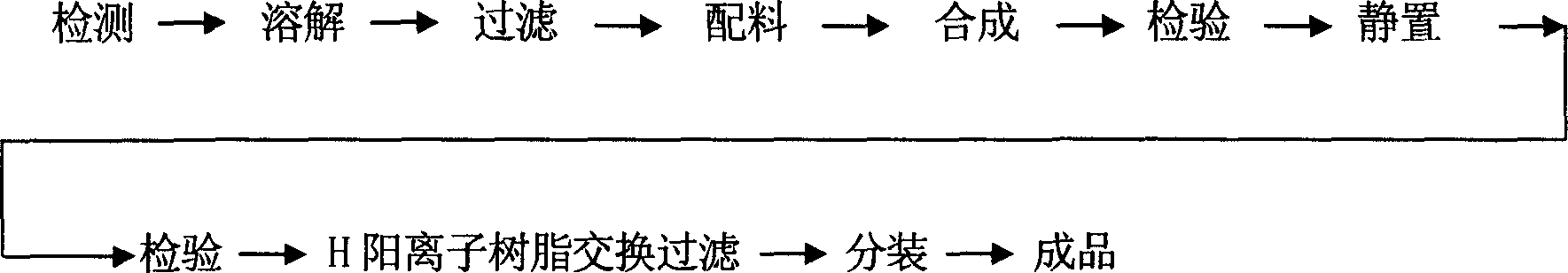

Method used

Image

Examples

example 1

[0037] Example 1, take by weight the following components of raw materials: A component main raw material: 840 parts of hydrogen peroxide (content 59%) for subsequent use; B component activator: 70 parts of acetic anhydride (content 98%); Component stabilization regulator: 20 parts of phosphoric acid (content 85%), 20 parts of acetic acid and 10 parts of salicylic acid (content 98%) for later use; auxiliary materials for component D: 30 parts of ethanol and 10 parts of polyvinyl alcohol are mixed and dissolved for later use.

[0038] Put the hydrogen peroxide of component A in the container, add the mixed and dissolved component B and D component acetic anhydride, ethanol, polyvinyl alcohol solution under stirring, add the mixed and dissolved component C solution after stirring evenly, continue Stir for 30 to 60 minutes, stir evenly and then stand still for 2 hours to prepare a disinfectant that improves the bactericidal activity of hydrogen peroxide.

example 2

[0039] Example 2, take by weight the following components of raw materials: A component main raw material: 850 parts of hydrogen peroxide (content is 58%) for subsequent use; B component activator: 60 parts of glutaric anhydride (content 98%) Standby; component C stabilizer: 20 parts of glutaric acid, 40 parts of benzoic acid; auxiliary material of component D: 30 parts of ethanol for standby.

[0040] Put the hydrogen peroxide of component A in the container, add the mixed and dissolved components B, C and D glutaric anhydride, glutaric acid, benzoic acid, and ethanol solution under stirring, stir well and let stand Within 2 hours, a disinfectant that improves the bactericidal activity of hydrogen peroxide can be prepared.

example 3

[0041] Example 3, take by weight the following components of raw materials: A component main raw material: 860 parts of hydrogen peroxide (content is 57%) for subsequent use; B component activator: propionic anhydride (content of 98%) 50 parts for subsequent use ; Component C stabilizer: 15 parts of propionic acid and 50 parts of phthalic acid are mixed and dissolved for later use; component D auxiliary material: 25 parts of ethanol for later use.

[0042] Put the hydrogen peroxide of component A in the container, add the mixed and dissolved component B propionic anhydride and D component ethanol solution under stirring, and stir for 30 minutes; then add the mixed and dissolved component C propionic acid and phthalate Formic acid solution, continue to stir for 30 to 60 minutes, stir evenly and let it stand for 2 hours to prepare a disinfectant that improves the bactericidal activity of hydrogen peroxide.

[0043]The product produced by this method is detected by the China Cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com